3rd Co-op Rotation

Adan

Experience Information

Employer: Metal Technologies Inc.

Job Title: Process Engineer

Major: Mechanical Engineering

Received Credit: Yes

Paid: Yes

Abroad: No

Description of the Organization

Metal Technologies Inc. (MTI) produces high quality metal castings for many different industries. Ravenna Ductile Iron (RDI) is MTI's Ravenna, Michigan facility. RDI specializes in casting ductile iron, which is renowned for its strength and ductility. RDI's diverse market includes automotive, commercial vehicles, hydraulics, railroad, and small engine. MTI is headquartered in Auburn, Indiana and consists of 7 different facilities, including one gauge producing facility. These facilities are spread throughout the midwest.

Description of the Tasks/Projects Completed

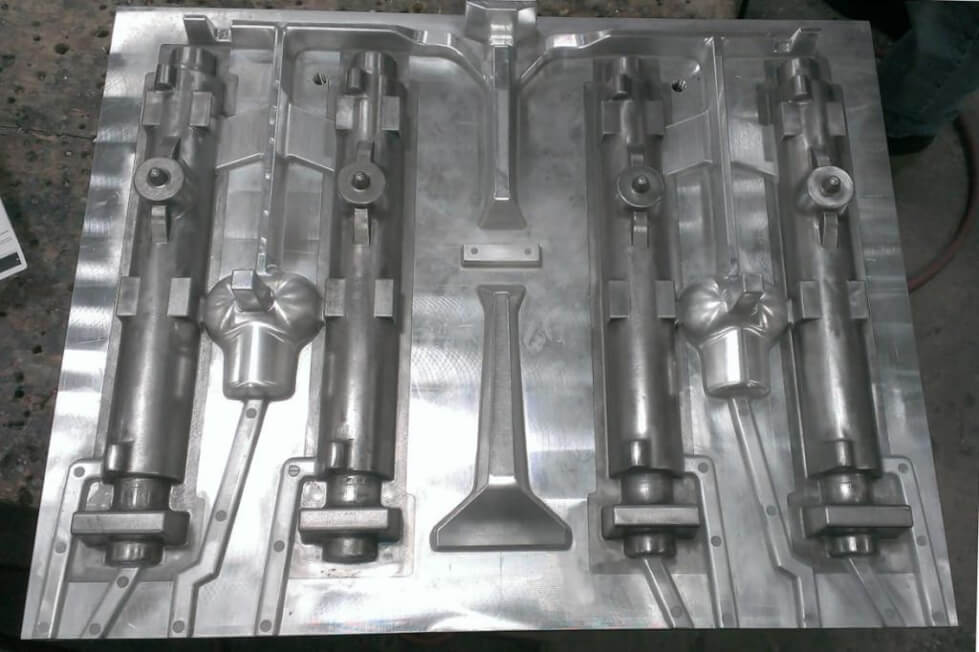

As new products are enrolled into RDI, my job is to design the gating pattern's that will allow molten iron to flow into casting molds. A large machine, called DISAMATIC, produces green-sand molds that contain negative space within them. Iron is poured into an opening at the top of the mold until the negative space is completely filled, and eventually solidifies. Each mold is capable of producing multiple castings, depending on the size and overall geometry of the casting. My job is to layout a design of how the castings will be positioned in the mold and a system of channels that will supply the entire mold with iron at an optimum rate. Iron must also feed into casting cavities as the castings solidify and shrink, which requires integrating reservoirs of iron, called risers, into the layout.

Skills/Knowledge Gained Through The Experience

Along with basic professional skills, I gained more insight on fluid mechanics and heat transfer. Fluid mechanics is a branch of science and engineering that is mostly understood through empirical data. That being said, there is still a lot of room to discover new methods for predicting the behavior of fluids, especially in specific industries such as metal casting. Trying to predict the behavior of the iron flowing through my mold pattern designs pushed me to think about applying methods learned in Fluid Mechanics, such as dimensional analysis and laminar/turbulent flow analysis. This experience gave me the opportunity to apply these principals and perform experiments on a daily basis, in a structured manner.

Favorite Part of the Experience

My favorite part of this co-op experience was having the opportunity to practice and test my creativity and professional skills. Going to class and getting the grades is small fraction of proving you have what it takes to be a practicing engineer. Gaining base knowledge is critical, but being pragmatic is just as important. I was given a platform to communicate and contribute to high-stake engineering projects.

How the Experience Influenced Future Career Goals

Toward the end of the semester, I was offered a full time position with RDI, set to begin post-graduation. While I still remain open to other opportunities, this job offer has me planning in the event of specific scenarios that are more realistic than ever before. While its uncertain that I'll remain with RDI for an extensive period, I think that I will likely stay in the automotive arena.