1st Co-op Rotation at Rose Medical: Winter 2023

Justin

Experience Information

Employer: Rose Medical

Job Title: Engineering Intern

Major: Biomedical Engineering

Received Credit: Yes

Paid: Yes

Abroad: No

Description of the Organization

Rose Medical is a small (100+ employees), but rapidly growing medical device manufacturing company. Rose is structured with president Todd Grimm, general manager Eric Vroegop, Director of Engineering, Chris Zandstra, and Director of Manufacturing Engineering, Steve Gronsman, as our leadership team. Chris Zandstra also leads Rose's team of project engineers who get to oversee interns and co-op students. My supervisor, Ryan Hoek, and the other project engineers focus on prototyping new products and improving the process for established products. Manufacturing Engineers work to design, build, and repair our advanced fixtures. Our products are manufactured in our five clean rooms by our two shifts of operators.

Description of the Tasks/Projects Completed

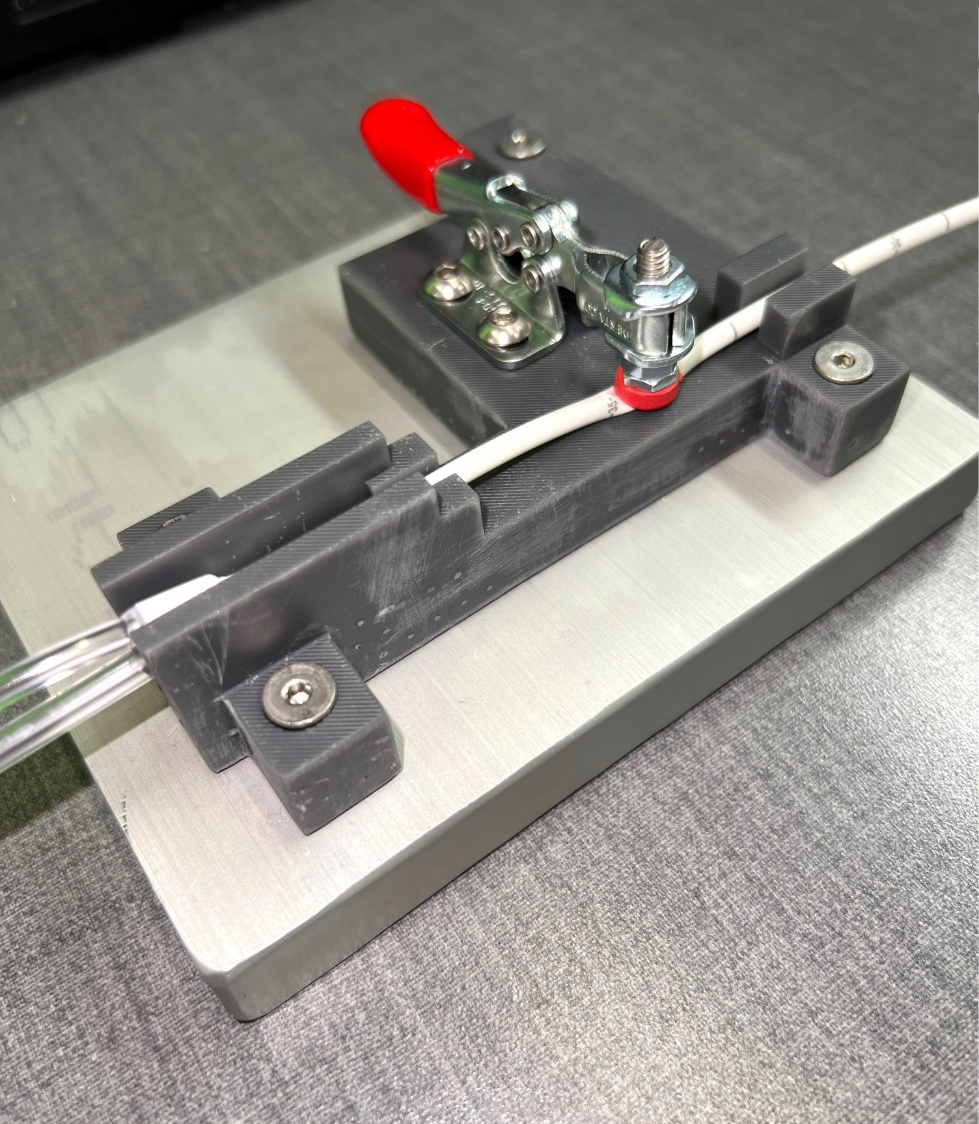

My first two weeks I spent a rotation of about 3 hours in the clean rooms to be able to see our processes and what Rose is capable of. From there I took the lead on two development builds for a new product transitioning from development to production at Rose. This involved doing much of the manufacturing by hand or with basic fixtures. Once these development builds were completed my work became focused on designing and qualifying new fixtures Rose would use to manufacture the the new product. In addition, I completed qualifications for the processes used in production.

Skills/Knowledge Gained Through The Experience

I learned to take measurements on a tool maker scope, Keyence, and optical comparator. I learned how to perform manufacturing processes of UV bonding, tipping extrusions, CNC hole punching and notching, leak testing, pressure decay testing, pouch sealing, and tensile testing. I was exposed to the documentation that comes with medical devices and learned to draft Installation Qualifications and Operational Qualifications, Corrective Action Requests, Non-conformance reports, and First Article Inspection Reports. I also learned to perform incoming inspections, process capability studies, IQs, Design of Experiment to find the process window for an OQ, and the OQ itself.

Favorite Part of the Experience

My favorite part of this co-op was improving my skills in SOLIDWORKS. I was pretty rusty when I started my rotation, but I quickly began to remember useful tips and learned new ones from my supervisor and coworkers. I had time to experiment with different features when designing a fixture and how to optimize a design for 3D printing. It was very rewarding to be able to see my design become real.

How the Experience Influenced Future Career Goals

By being exposed to the medical device industry, my long term goal of being a prosthetist has become more tangible. Seeing how medical device manufacturing can be improved with different fixtures shows there would be ample opportunities to improve prosthetic manufacturing processes. My time spent on SOLIDWORKS this rotation has given me a lot more confidence in my design skills. This will be extremely useful as additive manufacturing is becoming more popular for prosthetics. Finally I am very happy with my co-op choice. Rose Medical is a great work environment and place to learn. For the short term I know my engineering skills will continue to grow as I co-op here.

Internship Format

In Person