Students design, build new products for GE

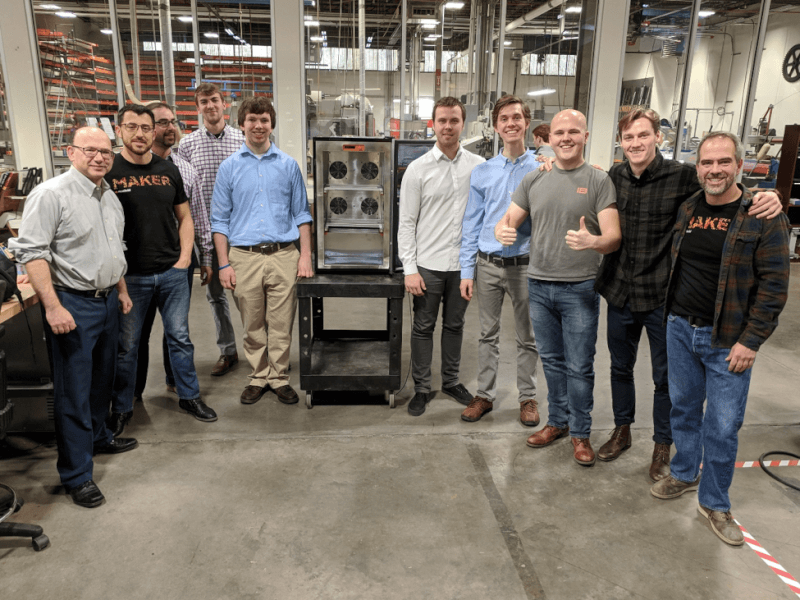

Students from Grand Valley and Kendall College of Art and Design recently teamed up to design and build two new home products for FirstBuild, GE Appliance's microfactory, or maker space, that drives innovation for its appliances.

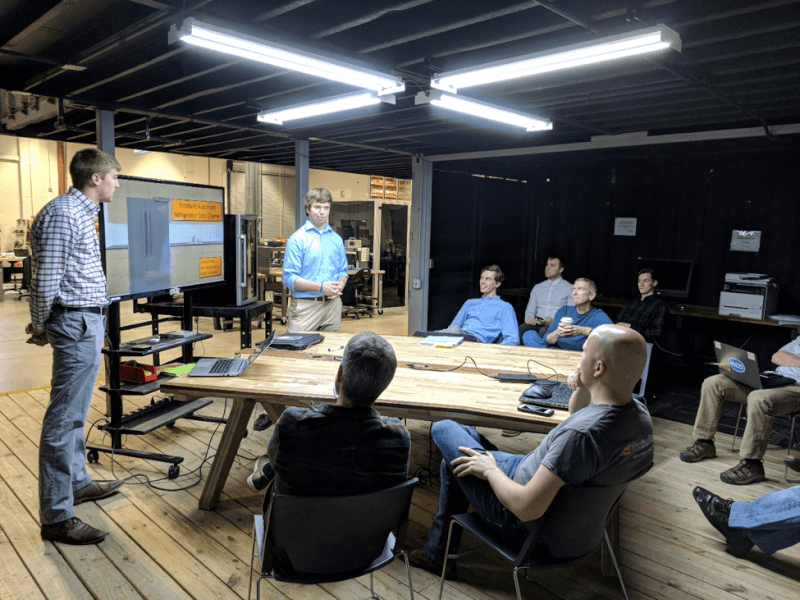

The students presented their prototypes — an automatic refrigerator door opener and a residential dry ager for meat — to engineers at FirstBuild in Louisville, Kentucky, in December.

Each team included three students: an industrial design student from KCAD, and an engineering student and a marketing student from Grand Valley. John Farris, professor of product design and manufacturing engineering at Grand Valley; Paul Lane, professor of marketing at Grand Valley; and Jon Moroney, chair of the industrial design program at KCAD, served as academic advisors and mentors.

"The students used design thinking to create solutions to problems," Lane said. "It’s an exciting, applied interdisciplinary project across colleges."

The students became connected to FirstBuild when they attended the company's Hackathon event last summer, which brought together builders, engineers and programmers from across the country who were tasked with creating new ideas and prototypes. The GVSU-KCAD groups spent the fall semester continuing work on their ideas.

Moroney said the experience included research, design, engineering and development.

"If anything mirrors what a successful start up should feel like, this experience got pretty close to it," he said.

Refrigerator door opener

Sam Oostendorp, a product design and manufacturing engineering major, worked on the refrigerator device. He said the group was tasked with making the refrigerator more accessible.

"Sometimes the seal on the fridge is tight and can be hard to open because the suction is strong, so we wanted to make it easier for people to open the door, especially for those with balance issues and those who use a cane, walker or wheelchair," said Oostendorp, from Grand Rapids.

The small device sits on top of a refrigerator and the group believes this is the first device of its kind.

Market research was an important part of the project, said Stephen Lietz, a marketing and entrepreneurship major from Chelsea. He conducted surveys, interviews and group discussions with active older adults and individuals who want to age in place.

"We talked to experts about fall risks and learned that 20 percent of middle-aged adults are affected by falls each year," Lietz said. "We also learned that the Baby Boomer generation wants to age in place; they want to stay in their homes and maintain their independence, which means homes need to be better equipped to maintain that independence."

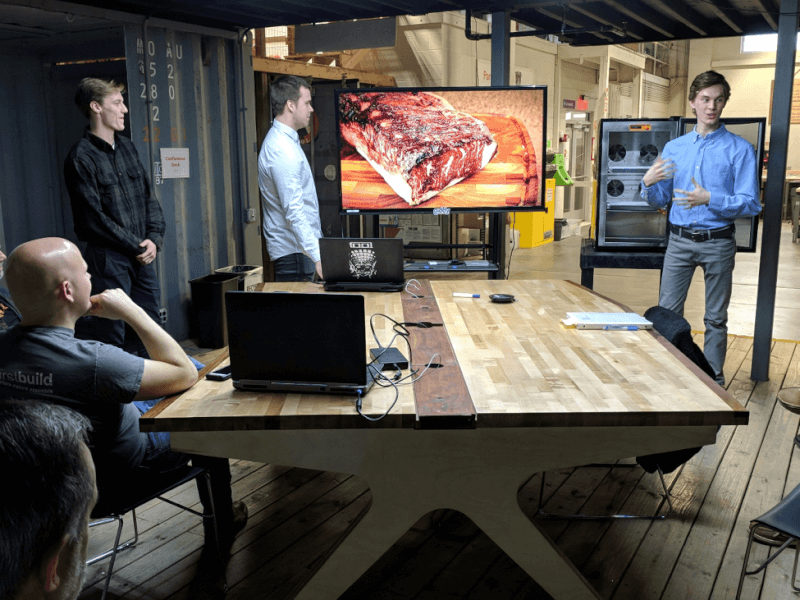

Dry meat ager

Zach Skogheim, an entrepreneurship and finance major, was part of the team that built the dry ager. The appliance stores beef for up to 28 days at a specific temperature, humidity and air flow to tenderize it and give it more flavor.

Skogheim, from Dearborn, was tasked with researching and creating customer profiles.

"There has not been a lot of marketing research done on residential dry agers, so it was difficult and interesting to create customer profiles," he said.

Skogheim's favorite part of the experience was traveling to Louisville to present the appliance and receive positive feedback from FirstBuild engineers.

"They are going to develop our prototype further and present it at a convention," he said. "It'll be exciting to be involved in the process and see where it goes."

Students on the refrigerator device team included Sam Oostendorp, Stephen Lietz and Caleb Teerman. Students on the dry ager team included Jordan Vanderham, Zach Skogheim and Richard Krauss.

Subscribe

Sign up and receive the latest Grand Valley headlines delivered to your email inbox each morning.