2023 Engineering Design Conference - Autocam Medical Team 3

Team 3: Autocam Medical - Project: Automated Press-Fit Assembly Cell

Team Members

Jenna Doyle

Jacob Ruemenapp

Chris Simaz

Pedro Takayanagui

Nathan VanHouten

Faculty Advisors

Dr. Chris Pung

Abstract

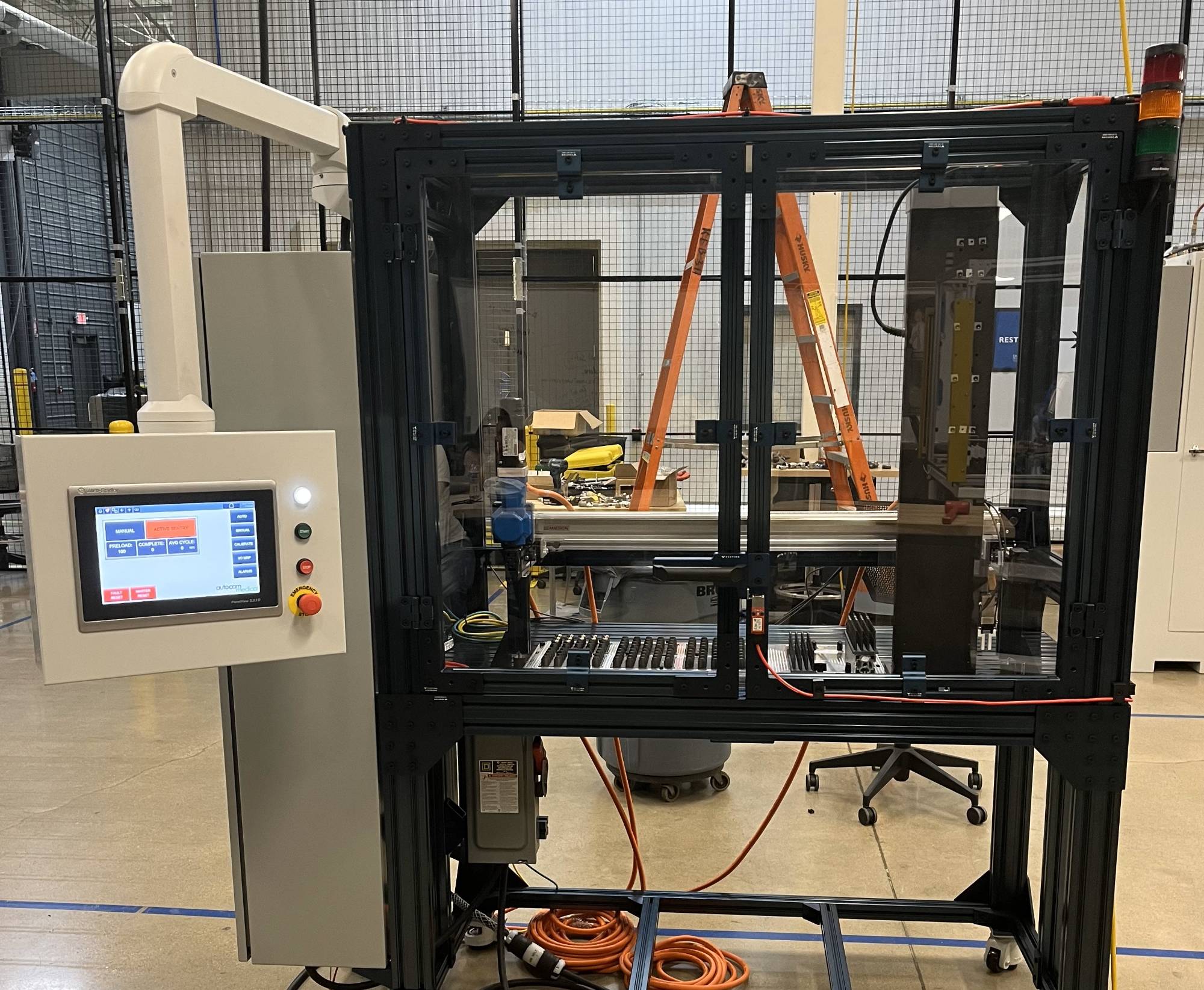

Autocam Medical is contracted to manufacture handheld surgical instruments used in the removal of cataracts from a human eye. The handpiece is composed of many subassemblies with two of interest, the endcap assembly and the sensor housing assembly. Each subassembly is made of two components, and each set of mated pairs are designed with an interference fit and must be pressed together for assembly prior to being welded. The current assembly solution involves an operator manually pressing together the components of the subassemblies using an arbor press. Therefore, the goal of this project was to build an automated assembly cell to perform the part handling and press-fit assembly operations with minimal operator input. The cell was designed to handle 5 different sets of parts as prioritized by Autocam, but can be expanded to accommodate future subassemblies. The main components of the design include a rolling aluminum extrusion machine enclosure, 3-axis gantry system, electronic grippers with custom tooling, variable force servo electric press with custom press fixturing, custom part pallets, and a PLC based control system. The design meets OSHA specifications as well as many internal specifications. The machine once implemented will be capable of exceeding 60 parts produced per hour.

Autocam Medical

Our Mission: Be the world’s leading contract manufacturer of high-performance, precision CNC-machined components for the most demanding medical applications.

[1689946895].jpg)