Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Electrical Engineering in the Architecture/Engineering Industry

Greg

Major: Electrical Engineering

I aided in the layout and design of lighting systems in new construction buildings as well as historical renovations. I also provided design assistance in the layout of power distribution systems within these buildings according to local, state and national electric codes. I provided assistance on a variety of different building projects for K-12 education, higher education (including projects for Grand Valley State University), historical building renovations, healthcare facilities, and large scale airport renovations.

Read More About Electrical Engineering in the Architecture/Engineering Industry

Test Software Engineer Intern

John

Major: Electrical Engineering

During the time spent here, I was able to be involved in many different areas. Anywhere from fixing problems that arouse in the production line (both hardware and software), to developing software and hardware used to test new units going through qualification testing. The task that I was able to spend the most time on was writing/updating code for stations that were being upgraded from Windows XP machines to Windows 7. Much of the hardware used in Windows XP is not supported in Windows 7, therefore the code had to be altered to communicate with a new pieces of hardware. This gave me the opportunity to learn how many different communication protocols work, and how to interface with many different components.

Co-op at JR Automation

Kevin

Major: Electrical Engineering

Projects and tasks included writing a PLC program to control and monitor equipment (heat gun) via interfacing Allen Bradley ControlLogix systems with hardware by generated tags (timer and control). Also, it included creating a Macro to assist in importing and generating data for use in software. It also included human machine interface design and implementation on machines to interface between machine and operator and also included data transfer via machine to databases.

Co-op I: Innotec Group

Lauren

Major: Electrical Engineering

I helped wire machines, build machines, create and update schematics, use CAD to design solutions, and helped move a launch product into production. I also was able to learn how to use different electrical equipment and conduct studies directly for our customer.

Working and Learning at a Great Company

Isaac

Major: Electrical Engineering

I worked on many projects for different engineers this semester ranging in size and complexity. I worked on schematic updates, PLC programming, circuit design, and circuit building. I also received the opportunity to go to Mexico as a new machine was being assembled there and assist an engineer. It has been a great experience being at Shape learning and working with the engineers here.

Controls Engineering Co-op

Marshall

Major: Electrical Engineering

This summer, I worked with machine controls, handling electrical drawings and documentation. I set up inputs and outputs in electrical panels and had them installed according to my design. I installed safety features and the electrical systems controlling them. I worked with PLC installation and programming, setting up and modifying the controls that determine how machinery behaves under certain conditions.

JR Auto

Adam

Major: Electrical Engineering

As a controls intern at JR Automation I was tasked with a variety of goals and jobs. This could have ranged from computer programming and debugging to swapping parts in and out of a machine trying to find the perfect solution to setting up a camera to accurately analyze a part.

Electrical Engineering Co-op

John

Major: Electrical Engineering

My main focus of this semester was trolling motors, however, I was able to spend a little bit of time in lighting. I soldered and potted boards, working on my coding skills and used a thermal imaging to find hot spots on boards during testing. I also designed an LED board for task lights.

More than just 9-5

Josiah

Major: Electrical Engineering

While at Disher I was able to work on many different interesting projects that I cannot describe to thoroughly. I was able to work with a company that makes car visors, on a project that is meant to redefine how visors are made and installed. I also was able to work on a project for a company that makes smart tables as well. There were plenty of smaller projects as well, but these were the two most important and interesting ones.

Engineering Co-op

Emily

Major: Electrical Engineering

I would split my work into three categories: projects, reports and busy work. Projects were things given to me that took more than a few days. Tasks of this nature occupied about 60-70% of my time. Reports were things that required the acquisition of data, the transformation of raw data, and the actual writing of a report. I had 4 of these within my 3 months at Gill. The last category is busy work. This is the doing of miscellaneous and small tasks. This ranged anywhere from cleaning, to assembling products and this is where the remainder of my time was allocated.

Twisthink Co-op Round 1

Audrey

Major: Electrical Engineering

I did a lot of research on machine learning algorithms for various applications Twisthink is working on, and also wrote some MATLAB functions. I also worked on a detection project, which included determining the optimal sensor for the project's application by researching and then testing. In addition to those projects, I did some temperature testing on several resistors by creating a circuit that simulated what would be happening in the product, and used an IR camera and an oscilloscope to capture the temperature at different time intervals.

Summer 2015 Engineering Co-op #1

Drew

Major: Electrical Engineering

electrical drawing changes, setting up PCs, setting up and wiring CNCs, backing up PCs, printing manuals, and assembling vendor manuals to name a few.

A Grand Experience, at Johnson Controls

Omar

Major: Electrical Engineering

I learned the specifications for two products that are being released in a future model of a major car brand, and applied that to the testing that was conducted on the software. I automated the testing on certain features to save time on current/future testing on this product and future products similar to it.

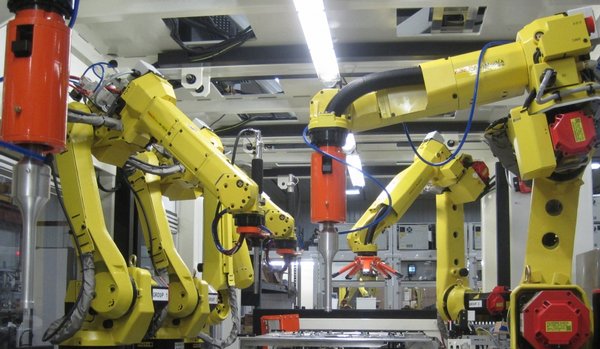

Welding Robot

Corey

Major: Electrical Engineering

I was assigned to the headrest launch division where we assemble machines that bend and put notches in the metal headrest tubes. My major task for the summer was to help assemble, program the PLC and program the HMI for a Weld Cell that used a robot arm to weld up to six different stations around a 7 sided structure.

DornerWorks EE Internship Rotation 1

Josh

Major: Electrical Engineering

I was placed as a Custom Logic Intern at day one. I had to quickly pick up the basics of Python and C++, as well as become loosely proficient in VHDL, 3 languages of which I'd never done any work in. Some of the main tasks I've completed were writing test cases for a Single Port RAM, and adapting a VHDL Pseudo-Random Number Generator to our libraries and adding functionality to it.

Third Engineering Co-op at Johnson Controls

Xu

Major: Electrical Engineering

I worked on software detail design documentation for software architecture design. I also participated in updating a database and project management documentation maintenance activities.

Future Gadgets

Omar

Major: Electrical Engineering

I worked on a product that will be released in a future model car, that I cannot disclose.

Project Coordinator

Sam

Major: Electrical Engineering

Coordinated an industrial automation upgrade project, to include researching available options, coordinating vendor meetings, creating and submitting request for quote (RFQ) documents, evaluating potential solutions. Future work to be performed includes negotiating terms of purchase, generating statement of work (SOW) documents, installing and testing hardware and software, developing a high-level user interface, and providing long-term support for the finished product.

Purchased components for, assembled, programmed and installed a large-format ambient temperature and humidity monitoring system for a controlled environment testing laboratory.

Industrial Eye Opener

Nathan

Major: Electrical Engineering

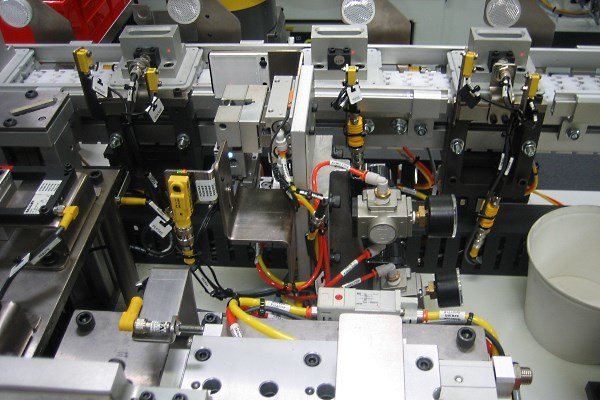

The picture attached is a picture of the biggest

project i had this semester. It controlled a

pneumatic cylinder that cycled in and out on a predetermined duty cycle and kept track of the # of

cycles. It was implemented to test the durability of

a new wire wheel system to de-burr the sharp parts.

EE - Controls

Ben

Major: Electrical Engineering

*Designed electrical, pneumatic and hydraulic prints for machines.

*Standard electrical codes and practices

*Wrote machine PLC logic and programmed HMI screens

*Some robot programming

*Camera/Vision work (part defect/presence)

*In general figured out how hardware worked and how to use it.

The JCI Experience

Timothy

Major: Electrical Engineering

Test development in support of Homelink and related testing procedures.

Embedded Systems Engineering Co-Op II

Kurtis

Major: Electrical Engineering

I was assigned to the custom logic team for this particular semester. Thus, I became familiar with writing professional VHDL code and I wrote VHDL modules for commonly used modules intended to be used for future SoC designs. Furthermore, I completed simulations to ensure VHDL module behavioral functionality.

I also wrote Python and C code for an internally developed custom logic software tool that enabled engineers to conveniently compile VHDL cores.

Lastly, I worked on integrating an Aptina camera board with a daughter card and a Stratix IV FPGA. The daughter card and the camera module weren't designed to directly interface with one another; thus, careful board bring-up and testing procedures were performed. PCB modifications were performed as well.

I also helped configure the video processing SOPC modules. Moreover, I wrote C code for the embedded NIOSII on the Stratix IV in order to configure the SOPC video modules. SignalTap was used to obtain empirical samples of the internal signals within the video pipeline for debugging purposes.

Cleanroom Chronicles III

Willy

Major: Electrical Engineering

I was assigned a couple of tasks as the semester went on. The main task was to design and manufacture (using in-house machines) a structural extension to an automated arm in order to fit the constraints of the environment it is operated in: a wet bench used in the College of Engineering's cleanroom.

Test Engineer

Jared

Major: Electrical Engineering

I was tasked with maintaining and developing functional testers in the final assembly department. This included streamlining testing to increase throughput, modifying test-methods to reduce scrap, and developing new tests to improve quality. In addition, I was involved with launching new products, which required performing capabilities studies and setting specification limits based on customer specifications. These are just two of many areas that required my attention.

My Time As a Controls Engineer

Christian

Major: Electrical Engineering

While on Co-op with Granco Clark I was placed in charge of 2 primary projects. The most significant of the two has actually gained myself and the company global recognition within our industry. I was tasked with and successful in testing, prototyping, and integrating wireless Bluetooth technology into our machines to allow for completely wireless I/O and communication between machines and the central processor. This made Granco Clark the first industrial automation manufacturer in the world to have integrated such technology into the automated metal extrusion process. It also resulted in a featured article by Light Metals Magazine that highlighted Granco's decision for its integration of wireless communication technology into the field of aluminum/metal extrusion.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.