Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

2nd Co-op rotation

Tyler

Major: Product Design and Manufacturing Engineering

I was asked to help design and build automation cells that assisted with the e-coating of the parts. This involved designing end of arm tooling for robots, building lighting cells to help illuminate the parts, and even coding the cell to help ensure the most efficient run times. I was also asked to design and build an inspection cell that vision inspected the packing of finished parts. This was done to ensure proper packaging. With this cell I was granted full design freedom and was allowed to code, build and design it how I envisioned best fit for the project.

Advanced Manufacturing Engineer

Eric

Major: Mechanical Engineering

Day to day activities includes quoting, part setup, tooling design, material deficiency report review and change order processing. On top of that, I also managed and co-designed three projects. The projects included a lathe, a automatic stripper and a sleeve machine.

CO-OP with Dominion Systems

Collin

Major: Computer Engineering

Projects I worked on range from bug fixes, quality of life improvements, new features, and converting legacy code to our new architecture. My main project was to complete a dashboard summarizing data that is created when a payroll is accepted.

Controls Engineering Co-op - 2nd Rotation

Jaret

Major: Electrical Engineering

This semester I spent some time doing electrical design and programming on machines, as well as some wiring and machine commissioning. I also accompanied our engineers and builders to a customer site in town on one occasion.

Engineering Co-op

Gabriel

Major: Product Design and Manufacturing Engineering

I spent the majority of the semester working on a new SATCOM antenna that we are trying to get contracted for. My responsibilities consisted of designing and modifying various components, coordinating with mold houses to have parts injection molded, designing and constructing interim fixtures to build samples of the antenna, physically building the antenna, and creating a drawing package for the antenna. I also completed similar smaller projects throughout the co-op semester.

M.E. Co-Op Experience with Team HS Die and Engineering Inc.

Steven

Major: Mechanical Engineering

During this second Co-Op rotation, similar to previous rotations, I spent the majority of my time working as a mechanical engineering designer. I was responsible for designing automated machines and their respective components. The first half of the rotation I spent most of my hours designing components to solve the current problems we were experiencing while designing, building, and/or testing our automated machines. A problem would arise during the machine's designing, building, and/or testing phases so I would be assigned to fix the problem. While performing these tasks I was able to gain trust and responsibility from my supervisor and co-workers. Later in the semester, I was given my very own machine to design. I was able to go through the whole machine design process. I collaborated directly with the customer while designing the machine. I also continued to perform problem solving side projects while designing my own machine. In summary, I performed and learned a lot within the mechanical engineering design field. I spent 500+ hours using SolidWorks 2018 as well as 20+ hours of hands on building.

Read More About M.E. Co-Op Experience with Team HS Die and Engineering Inc.

EMC CO-OP 2

Brittany

Major: Electrical Engineering

As a co-op student I was tasked with completing several tests for clients, analyzing and simulating signal integrity projects, and assisting in the development of the company website.

West Michigan Sports Commission Internship

Holly

Major: Sport Management

I continually worked with vendors to organize services like catering, tents, welcome information, and more for upcoming events. I was able to create marketing materials to promote our events. When event days came, I was on-site to assist with setting up, guiding volunteers, and answering questions to visitors.

Engineering Co-op

Nora

Major: Interdisciplinary Engineering

At Twisthink, I worked in the AI and Computer Vision team. This team is responsible for creating systems that map perceived environmental conditions to suggestions, answers, decisions, and autonomous actions. The projects I worked on were in the early research and development phases. Our goal was to identify the most effective detection system within given constraints. To do this, we took an iterative approach, evaluating the effectiveness of several sensors and their associated detection algorithms. One project included the development of a sensor and algorithm to detect the strokes of a deep well hand pump utilized in third world villages. The purpose for this was to track the health of the pump over time. Currently, if a pump breaks, it takes time to mobilize the resources to fix it, leaving locals without water. The device I worked on will use signal processing and machine learning to process signals from special sensors. The processed signals will be sent to the cloud allowing the health of pumps to be monitored and resources allocated prior to their failure.

The Grandest Time

Marisa

Major: Sport Management

I completed anything from daily credit card reports to putting on our annual spring sale at the end of the year. I handled the money before and after every event for both Louie's Locker Room and Tickets. I stayed on top of online orders and inventory for our merchandise. I created the events within our ticketing system for the upcoming seasons. I supervised and managed ticket and merchandise sales interns at all home events.

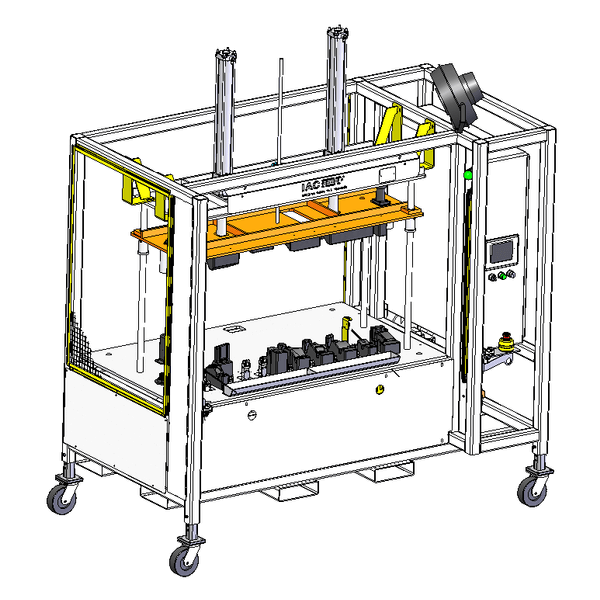

Koops Mechanical Engineering Co-op

Jacob

Major: Mechanical Engineering

During my co-op rotation as a member of the Koops mechanical engineering team my primary responsibility was to work on the mechanical design of custom automation equipment. The main tasks associated with this were the creation of accurate and detailed CAD models, part drawings, and bills of materials (BOMs). During the winter semester I had the opportunity to work on numerous projects in both assisting and primary designer roles.

Co-op Rotation 2

Kyle

Major: Mechanical Engineering

One of the main tasks I completed during this co-op rotation was creating and managing graphics for completed projects. Graphics include floor plans, water systems, and air handlers. It was my job to ensure graphics were ready for technicians when it was time for them to program the graphic and get it ready for the customer to use. Another task I performed was creating record drawings. This entailed going into the drawings created by one of the project engineers and making changes. The changes made were a result of a technician realizing that something isn't portrayed accurately in the drawings while in the field. They would then mark up the drawings and give them to me to update.

EMC Co-op

Nicklas

Major: Electrical Engineering

Over the semester I worked on products for several companies from various industries testing and debugging their products. I also worked on internal lab infrastructure projects to make testing more efficient and accurate.

Production Support Engineer

Aidan

Major: Mechanical Engineering

This rotation focused on manufacturing and was more closely tied to production. A lot of time was spent on the floor, building confidence in working with the team, scrapping out bad parts, and responding to alarms. After that knowledge base was built, Some Continuous Improvement projects began, such as dashboard setup, and line rework/modifications.

A Winter at Phase 1

Benjamin

Major: Electrical Engineering

Tractor Downforce- Updated a pre existing system that controls the depth of planting wheels.

Pizza Chiller- Updated a system that dispenses water at the correct temperature for making pizzas

IOT Outlet - Measured the RF characteristics of printed antennas and changed part to balance them

BLE beacon- Prototyped a Bluetooth beacon that will be used to track portable road segments

BLE pressure sensor- Measured the connection quality of different BLE sensors.

SAF Holland Electrical Co-Op Rotation 2

Alexander

Major: Electrical Engineering

The Electrical Engineering department performs work related to all aspects of product development and production. The tasks have been hands-on and provide great opportunities to work on the development and production of company products. Projects in this rotation included commercial vehicle electrical system network analysis, web server management, microcontroller evaluation, programming, and testing, and extensive research for product development.

EGR 390 Co-op 2

Jacob

Major: Mechanical Engineering

Throughout the co-op semester, I worked on several K-12 education projects that involved designing new mechanical systems (HVAC, mechanical equipment, and domestic plumbing). I was presented with a higher sense of responsibility from my previous co-op by being given the task of fully designing a new HVAC system for an elementary school with the guidance of a full-time engineer.

Advanced Product Development

Kelly

Major: Product Design and Manufacturing Engineering

This semester, I further developed my CAD skills with projects such as a camera mount, outside mirror blindzone signal, and electronics storage unit. I learned how to operate the CNC as well as how to test electrochromic reflectance in a temperature-controlled chamber. Over the course of the semester, I developed a standardized lighting specification procedure.

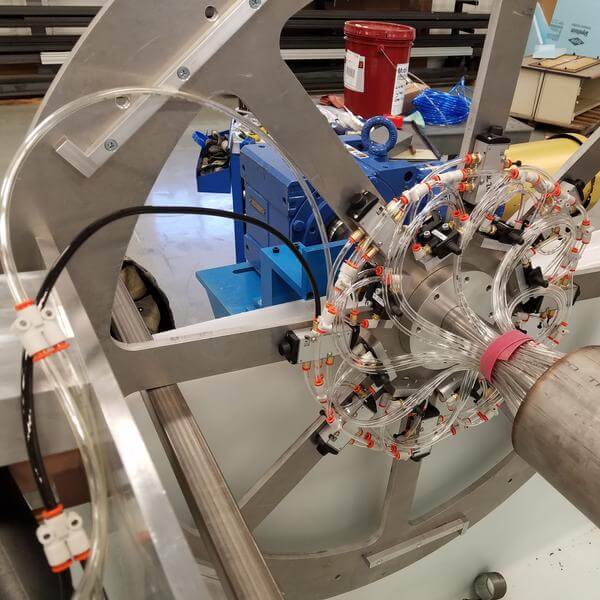

Hutchinson Co-op 3

Alex

Major: Mechanical Engineering

At Hutchinson I was able to be involved in a variety of different tasks and projects in different labs and project groups. With the product development group I worked with I was able to test a variety of transmission and engine mounts for different performance and damping characteristics. I helped manufacture and modify prototype parts to tune performance. I also helped design test fixtures for parts for static and torsional testing. I experimented with design modifications to a part component using FEA analysis to look to decrease component mass. I assisted in developing bracket designs to meet stress targets and tooling clearance requirements. I helped conduct production process rate studies as well. Along with this I helped assemble and build a prototype heating unit for rubber to metal bonding and conducted heat studies. I also developed procedures for testing metal insert material compression yield strength.

EBWE First Rotation

Jacob

Major: Mechanical Engineering

I was able to design components being used on the floor today, quote them, and have them built to spec. I was also able to perform finite element analysis and strain gage testing as well. I created many CAD drawings for my fellow workers and wrote many engineering reports to follow up on my engineering experiments involving torque and load tests.

Scrap Metal Engineering

Alex

Major: Product Design and Manufacturing Engineering

Projects included reverse engineering cyclone systems, designing airlocks, overseeing the design & production of four semi truck trailers, and helping organize the re-location of one of our recycling plants. Other projects included minor plant improvements and additions to our manufacturing processes.

Rotation 2 for CAE Role Co-Op Student

Adam

Major: Product Design and Manufacturing Engineering

Magna Mirrors of America gave me the opportunity to train with a senior CAE (Computer Assisted Engineering) engineer to learn Finite Element Analysis (FEA) skills as well as Optimizations techniques, and other CAE tasks. Some programs that were assigned over my second rotation included completing FEA analysis and CAE analysis of Honda's T90A (Civic) handle program, Ford's U611 (Aviator) handle program, Toyota's 890B (Tundra) mirror program and multiple other smaller jobs that were required of me during the 16 weeks of the rotation. Although FEA and CAE took most of my time at the company, I was involved with multiple physical part testing and data acquisition for the U611 handle program, as well as GM's T1XX (Silverado Trailer Tow) mirror programs.

2nd Co-op Rotation at Gill Industries

Leif

Major: Product Design and Manufacturing Engineering

This semester, I split my time between process engineering at a plant level and product engineering at a corporate level. In process engineering I worked closely with operators and team leaders on the production floor to monitor and improve line efficiency in several ways. Some of the smaller projects I completed include updating operator work instructions, modeling small fixture parts from drawings, and maintaining a daily throughput line chart that reported efficiency of one of Gill's larger volume lines. I also completed several larger projects like doing a time study on one of Gill's larger volume lines and completing an engineering time breakdown of every operation in the line, finding inefficiencies, and suggesting steps to improve the line. Another large project was measuring a feature on a welded subassembly to complete a study seeing if there was a correlation between weld fixture, stamping, and gap dimension. By far, my largest project while in process engineering was designing, ordering components for, and fabricating a flow rack for a line in order to potentially increase efficiency. The second half of this semester, I spent my time with the corporate product engineering team. Some of my miscellaneous tasks in this department included testing and measuring parts for quality concerns and benchmarking, comparing different revision levels of drawings, and gauging parts to see if they matched coordinate measuring machine (CMM) data. Most of my time in this department was spent preparing to take over the work of a project engineer that went on maternity leave at the beginning of April. This included attending all of her meetings with her in order to gather all of the information I would need to be self-sufficient throughout the product launch. My involvement in the launch included traveling to machine builders to oversee trial parts, speak with engineers from the customer, and do light rework on some parts. My experience in this stage of my co-op allowed me to step right into a full product engineering role and test my professional abilities.

The Hidden World of College Athletics

Courtney

Major: Sport Management

More often than not, there are huge chunks of students who want to work in college athletics. They aspire to work alongside the top Division 1 schools within their athletic programs. But where does one start? In the marketing department for athletics, we are responsible for fulfilling promotional and sponsorship contracts, develop marketing strategies to engage with students, and execute those marketing plans on game days.

JR Automation Controls Engineering Co-op

Robert

Major: Computer Engineering

The tasks I completed were largely dependent upon the projects I was placed on, which I am not at liberty to disclose details about. In general terms, I did a great deal of HMI work, configuring and programming of numerous devices, PLC programming, working with robots, 2D CAD work, working with servos and gantries, and debugging. I was trusted with my own small cell to work on independently (though I frequently received help), and was also allowed to travel and play a role in the installation of a project at the customer's location.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.