Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Magna Co-op

Zakary

Major: Mechanical Engineering

Throughout the course of a semester, I put to use my skills learned in classes to help improve on the design of a robot used for cycling. I was also able to help with determining how parts would fit together for a new mirror as well as complete multiple kinds of testing to determine if the mirrors were meeting required standards.

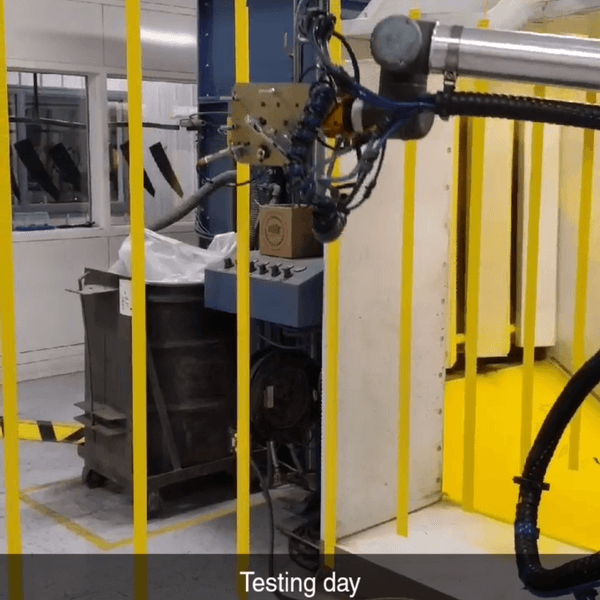

Axis Automation Second Co-op

Mason

Major: Mechanical Engineering

This semester I worked on a variety of projects on the back end of the design process. This consisted of detailing prints for parts and assemblies, redesigning and updating existing designs, verifying robot loads, and evaluating robot and fixture interaction.

Individual Community Living Service Mentor

Connor

Major: Psychology

I worked as an Individual Community Living Service (ICLS) Mentor. In this job, you are paired with individuals with different disabilities and are tasked with helping them meet their goals (which have already been established) within the community. This can range from ensuring they are conducting themselves in a safe manner, to not excessively waving to strangers or using inappropriate boundaries - it is super unique by individual.

Production Assistant Internship

Maggie

Major: Communications

Throughout the semester I helped produce the show the Grand Valley State Sports Report. I wrote the script every Sunday and worked in studio on Monday mornings, usually working behind the camera and occasionally monitoring audio. In studio, Jake Levy hosted the show and interviewed coaches of GV sports. I was also able to help film some of the sports that premiered on the show.

Structural Concepts - Engineering Co-op Rotation #1

Treman

Major: Interdisciplinary Engineering

Over the course of my first rotation, I brought several engineering designs to life in our facilities to address issues on our manufacturing floor.

My first designed part was a mobile stainless steel cover for hydraulic pumps that power lift tables on our assembly lines. This design was adopted by several lines in our facilities.

From there, I practiced many different skillsets to assist our continuous improvement team with different areas of our manufacturing facilities. I collected and analyzed data of the different types of tools being used on our assembly lines. This was in an attempt to create a collective tool bag which each worker would get for use on the line due to tools often being misplaced, causing unnecessary downtime looking for the proper tool.

I made an excel spreadsheet to help rethink how we organize our fastener storage area. As it was, fasteners were hard to find because they were all in boxes and out of order. I made an excel spreadsheet which served as a way to enter in descriptors of a fastener (size, color, name, description, etc..) and would then point you to the specific location of the fastener to save workers time.

I designed a storage unit for rubber bumper that is used on sharp edges of our cases. This storage unit is used in multiple locations within our warehouses.

I helped create a customizable workbench that served a dual purpose by also functioning as a computer stand with retractable keyboard holders and a pegboard backing. This design is currently being adopted by all areas of our warehouses and will likely be built 50-100 times.

There were many more small creative design projects similar to the ones described previously. Often times, I worked on open-ended problems with no clear solution and was given creative freedom to develop a solution as I saw fit.

My final and largest project was the implementation of machine data collection software in our sheet metal department. I built up all of the user-interface required to implement data collection of the causes of downtime within the department as classified by our operators. I also built up the backend of the software to ensure that the hardware collecting data within the machines was functioning and reporting properly. I worked with area leaders within sheet metal to implement this software and build a routine for using it and logging data on a daily basis. I also set up several styles of reports to use for data analysis which will then be used to tackle large issues of downtime. The software even provides us with clear cost justifications for our machines and will allow us to make better decisions in the future regarding the area.

Read More About Structural Concepts - Engineering Co-op Rotation #1

Co-op Student at RDI - Semester 1

Andrew

Major: Mechanical Engineering

The first half of each day began by cleaning, inspecting, and organizing the pattern plates that were recently ran. During this time, various other tasks could come up including shipping out or receiving patterns, stamping unmarked patterns, and watching a sample run for a modified or new pattern.

The second half of each day usually consisted of various jobs on the CAD program Creo. I reverse engineered patterns on transfer tools and created new tools from scratch. Molten iron flowing through the created patterns was simulated in a program called Magma. These simulations were then used to make modifications to potential new patterns as well as improvements to existing tools.

Creating a Seat at the Table

Patrick

Major: Product Design and Manufacturing Engineering

I participated in many projects in my experience at Genesis Seating. Shelving units and manufacturing fixtures were created to improve ergonomics and efficiency within the cell of a main chair line of Herman Miller, as well as cell layouts, which were redesigned to increase efficiency. A proposal was created for the re-design of an assembly station for the Eames Plastic and Wire chair line from Herman Miller. Torque specifications were gathered for battery, pneumatic, and electric drills from each cell in the factory. Finally, I re-designed a leather buck to expand and contract to improve ergonomics for the leather cutters.

Magna Mirrors Co-op Experience

Joshua

Major: Mechanical Engineering

I did a variety of tasks. Much of my time was spent in preparation for engineering builds for prototypes, studies, etc. This required me to gather mirror components and arrange for time to be spent on the line. I also performed studies/gathered measurements. This usually came in the form of dimensional measurements, reflectivity measurements, angle measurements, and Instron measurements (pull-out strength, for example). I also had several longer term assignments, such as designing a portable "suitcase" tester for a new video mirror, and a role in producing, testing, and statistical analysis of mirrors built with experimental aluminum tubes (replacing steel).

Searching for Diversity in Film

Samantha

Major: Writing

At the beginning of the internship I was tasked with writing a few short reviews and a full length article per week. Later in the internship I was asked to also edit articles so my writing load was lightened in order to give me time to edit three or four articles a week.

Second Rotation

Kasonde

Major: Computer Engineering

My responsibilities with JR Automation had two categories; environmental documentation and machinery commissioning.

Environmental documentation included researching devices to be integrated into a project, and ensuring the device met the environmental and fire retardancy per the client's specification. On the other hand, machine commissioning included certifying that all the integrated parts and devices, perform their intended functions well and efficiently.

Herman Miller Co Op - Design For The Good Of Humankind

Xue Hua

Major: Electrical Engineering

The majority of my responsibilities were split into two categories: The Database Project and Work Orders. The Database Project was an 8-month project where I was responsible for programming, designing, testing, and implementing an asset management system. This system would be used by the entire Controls Department at Herman Miller. The specifications included vigorous querying needs, functionality to interact with the data, and an intuitive user experience. The goal was to manufacture an asset management system where the entire Controls Department could manage its internal assets and its various details and information such as IP information. On the other hand, Work Orders were work requests from other areas of the company to support production. The one I enjoyed most was implementing a sensor to detect the edge of a panel to eliminate a design error. This work order was on the back burner for around a year before it came to me. It was a 3-month project where I had to research sensors, calibrate them precisely and implement them into the existing PLC program. This specific was project was a success and the steps I laid out were administered to 7 other machines. This was an example of a typical work order.

Read More About Herman Miller Co Op - Design For The Good Of Humankind

Third Co-op Rotation

Jordyn

Major: Mechanical Engineering

I analyzed customer verbatim and complaints, benchmarked competitors, and made possible recommendations to improve customer satisfaction

Third co-op rotation at Autocam Medical

Zachry

Major: Product Design and Manufacturing Engineering

For my third rotation I took on a full manufacturing engineer's role. I focused mainly on new product launches and production support for our bone screw division. I also completed many continuous improvement projects for secondary operations such as bead blasting and electropolishing.

DeWys Manufacturing Co-op

Zachary

Major: Mechanical Engineering

In my final co-op rotation, I worked mainly on a project which sought to add a collaborative robot to the powder coating line on-site to help with quality issues of the powder application. I did lots of CAD design and planning, and the build and testing will be happening shortly. It was overall a great semester and I learned a lot from the experience.

IPM Mechanical Engineering Co-op #3

Logan

Major: Mechanical Engineering

I was tasked with various degrees of project work, where I designed, modeled, and assembled hundreds of parts to form a specified conveyor for the application at hand. I also worked on standard library components to help improve efficiency for designing in future similar projects.

Final Co-op at Medical Device Manufacturer

Emily

Major: Mechanical Engineering

Being my third co-op rotation at Rose Medical, I had the opportunity to work on more challenging and complex projects. I worked mostly independently on protocols-- drafting, receiving customer approvals, executing, and writing reports. The nature of these were for installing new tooling/fixtures, updating tooling, manufacturing process qualifications, operational (verifying machine settings for various products) qualifications, measurement system analysis validations, and numerous customer requested validations. The vast majority of these were for two projects with two project engineers at Rose Medical; I reported to both for the duration of the semester. I also was given the opportunity to run my own project for a company requesting prototypes of a tipped cannula. For this, I was the point of contact for the customer. I created a schedule, designed four fixtures/tools for the tipping process, got quotes for tooling, and placed orders for tooling and material. The project reached a bump in the road with ordering the customer specified material with the customer ultimately changing material; therefore, I didn't get to create any prototypes. Instead, I learned bounds and leaps more by this hiccup through difficult communications than if everything had gone smoothly. In addition, I was a point of contact on one of my supervisor's projects where I sat in on meetings and communicated daily with the customer, answering questions and providing recommendations. By doing so, I kept the project's rapid pace while my supervisor was out of the office and aided getting product out the door during crunch time. I executed multiple DOE's for different products to recommend settings for thermal welding, medical pouch sealing, and cannula bending processes to multiple engineers.

L3Harris - 3rd Rotation Co-Op

Michael

Major: Electrical Engineering

Throughout the semester, I worked on a lot of different projects that involved things such as library development, program verification, and hardware maintenance and repairs. Most of the time spent during this semester was dedicated to writing the testing program that will be used for an upcoming product, which I was primarily responsible for.

Electronics Design and Manufacturing at Ram

Joe

Major: Interdisciplinary Engineering

This semester I worked on a number of products that Ram is currently designing for different clients. These include an IoT backup pump system, a capacitive touch desk lamp, and a number of power supply products.

Final Rotation at Phase 1 Engineering

Andrew

Major: Electrical Engineering

During my third co-op rotation, I designed and built a test fixture used to test multiple device radio communication. I aided in the analysis of the data collected with this test fixture.

Performed medical grade stainless steel welding on an expensive RF prototype.

Upgraded existing testing module prototype to have use a stepper motor. Wrote controller code and installed stepper motor in place of existing motor configuration.

Aided in the design and development of a photo-voltaic solar harvester for use in energy intake analysis. Built and tested all working prototypes. Created data analysis tool using java to store data in the database and then analyze data based upon user input parameters.

Performed data collection with Thermo-Electric generators to determine energy output versus temperature drop across several devices.

3rd Rotation at Innotec

Cameron

Major: Electrical Engineering

I completed a variety of projects this rotation. For example, I completed process improvement projects such as machining steel fixtures to improve automation, improving quality check reliability by performing simple worst case circuit analysis, designing 3D prints for machine fixtures, implemented a data logging feature on a production line, and more. I was given the monthly responsibility of 5S for my team, which involves streamlining everyday tasks such that the team operates in a ýleaný manufacturing environment.

3rd Co-op Rotation

Avery

Major: Product Design and Manufacturing Engineering

I was assigned tasks throughout the semester that required me to design new tooling to make parts and to modify old tooling to improve our stamping processes. I also worked on a task researching new 3D printing technology that we might want to implement at Trans-matic

Engineering Co-Op rotation 3

Dylan

Major: Mechanical Engineering

I started off the semester doing a robotic welding fixture for a local manufacturing company and then I went more into product development, specifically with landscaping tools and power equipment.

Engineering Co-op Final Rotation Experience

Abbey

Major: Mechanical Engineering

I spent the semester mostly designing and detailing parts and assemblies using PTC Creo software.

EGR 490: Co-op 3

Ryan

Major: Mechanical Engineering

During my co-op, my main responsibility was to execute projects that improve upon our manufacturing processes. Some larger projects included redesigning/refreshing major components of our machines. In addition, I was also responsible for a portion of the day's production, materials handling, preventative maintenance, and spare parts management.

Dematic - Rotation III

Aleksandr

Major: Electrical Engineering

I was put on a project and I was working on controls layouts for most of my rotation. This involves placing devices on the conveyor, routing power cables, routing network cables, and then creating layout drawings for required views (power bus, networks, devices). I also spent some time during my last couple of weeks training/guiding a new engineer through the entire process of creating the controls drawings (including using the software the company uses) so that once I left he would have the knowledge and skills to work on an area on his own.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.