Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-Op at Johnson Controls

Dan

Major: Electrical Engineering

I am responsible for process development. I completed electrical schematics for a conveyor oven and developed a laser weld for hermetic sealing of lithium ion cells.

Steelcase Summer

Janelle

Major: Computer Engineering

Each week, I was required to update software for the plant system. Each section in the plant had a "Golf ball" HMI. The plant user had to choose certain components on the screen and the program shows if the part in front of them matches what components it is supposed to have. In other words, says if the part was built correctly. I also wrote new parameters for barcode scanners as a creative new input method. I also changed C++ based code that creates the labels for reports which incorporates SQL language. The biggest part of my impact was when I led a project that creates shipping boxes. The boxes are built so that there is minimal waste. Through code, I had to analyze the size of our products and calculate which size of boxes would fit the most products as well as create minimal waste. In addition, I gained experience working with RFID barcodes and TCP connections.

GVSU Athletics Intern

Caity

Major: Sport Management

We were responsible of running all the promotions during the sporting events at GVSU. We also helped promote and market the games to the students as well as the community outside of GV.

ME 2017 First Coop

Tim

Major: Mechanical Engineering

Primary projects i worked on were two innovation projects, some quality testing for various programs, and a wide variety of miscellaneous non-PDP development.

Grand Rapids Griffins Youth Foundation Internship

Chase

Major: Sport Management

I helped in the planning and the organization of the Great Skate Winterfest. Helped to organize, plan, and set up for the foundations Career Day. Created a comprehensive end-of-year survey for parents and kids, and then broke down the results and data, and presented it to the board of directors. I helped to find grant opportunities for the foundation. I also did research and statistical preparation for Griffins game day radio broadcasts.

Read More About Grand Rapids Griffins Youth Foundation Internship

Arconic (APP) - 2nd Rotation

Clark

Major: Mechanical Engineering

I worked in the Research & Development department, so my range of tasks was diverse. As a mechanical engineer I got to design bucket elevators, guarding, fixtures, and several small projects along the way. I was also involved in some small automation projects and was introduced to robots and the logic behind them.

Cyber-security Co-Op

Evan

Major: Computer Engineering

I worked on performing a variety of security assessments for companies around the country. This included direct penetration attempts (Hacking) from both external and internal connections as well as performing deep dives into corporate systems and policies to ensure the company's security.

EGR 390

Jake

Major: Mechanical Engineering

I am a design engineer, so I create drawings and models of filter presses according to the customer's selected options. Occasionally I will help out with creating aftermarket retrofits to competitors products.

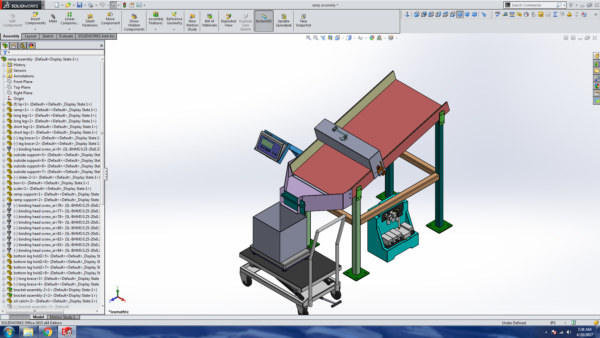

Dematic Co-Op II

Zach

Major: Mechanical Engineering

While at Dematic, I have completed a wide variety of engineering tasks. I work on the Amazon Mechanical Engineering team which designs conveying and sortation systems for Amazon Fulfillment Centers. My day-to-day functions include making/updating drawings in AutoCAD. These drawings are sent to installation teams on the jobsite to aid in the installation of conveying systems. I also order parts that may have been missed or ordered incorrectly during primary order entry.

Yanfeng Automotive Interiors

Morgan

Major: Product Design and Manufacturing Engineering

This semester I worked in a plant as the manufacturing engineer on three door assembly lines. As part of that, I handled a wide range of tasks as they came up. This included working on the manufacturing line to gain experience, resolving safety and quality concerns, repairing machines as needed, leading a work re-balance to eliminate unnecessary production, and helping with on-going updates to equipment and processes.

Trans-Matic Engineering Co-op

Sam

Major: Mechanical Engineering

Working as an intern for the engineering department I completed a wide range of tasks. Like my last semester, I handled a lot of updating and redesigning existing tooling in the presses. Each production job has tooling originally designed that fits into the presses to produce specific features on the part. These designs go through constant changes as the tools wear down or industry standards change. This was all done using the latest version of Creo (3D CAD software). Besides just redesigning existing tooling I got to work with other designers on twelve new tooling jobs, and was able to take a lead role on two other new tooling designs. I also handled the design work for all gauges and managed engineering drawings for the product launches.

EGR 290

David

Major: Electrical Engineering

I was assigned a main project to work on throughout the co-op. This project had me design a peak current meter that was capable of measuring the peak on time current as well as continuous current of all types of industrial LED driver products. The meter was capable of measuring a wide range of current. I also worked on many smaller projects that allowed me to get experience with a variety of products.

2nd Co-op Rotation at Emerald Corporation

Trent

Major: Product Design and Manufacturing Engineering

During my second rotation of co-op at Emerald Corporation I was able to take charge and lead a few new projects. One of the projects was to come up with a new way to ensure traceability on all of the parts that are painted on our paint line. I was able to talk with many different printer and label suppliers to determine a plan of action to implement printers on our unload side of the line. These printers will allow Emerald to place labels on every part which will include important information about that specific paint run. If we have a quality alert from our customer we will be able to quickly determine a root cause based on the information printed on the label. Along with the leadership roles I was still able to enhance my CAD skills by designing new fixtures and even making edits to our plant floor blueprint.

2nd Semester Co-op

Karla

Major: Electrical Engineering

Mainly, I worked on maintaining and writing tests for a Hardware in the loop test system. I also performed manual tests, tech work in the lab, and rf antenna testing.

Gentex: Production Support

Zachary

Major: Computer Engineering

Initially, my role as a production support engineer was to learn all about the layout and flow of our production lines. I was tasked with debugging and fixing any problems on these lines (especially software-related ones). If I couldn't solve the issue, then I would escalate the problem to the appropriate support personnel. I also dealt with some of the aspects of managing the production team members who worked on the lines.

As the semester progressed, I transitioned more to focus on my main project - a live dashboard that monitors the status of the production lines and detects any ongoing problems (downtime, scrapped parts, etc.). I designed this dashboard from scratch, although many of the events I needed to monitor already had code set up to provide a means of tracking each line's performance. My final task of the semester focused on distributing this dashboard and dealing with the issues that arose on its deployment, as well as tweaking the code to work well with the varying structure of our production lines between buildings.

X-Rite Co-op Experience

David

Major: Computer Engineering

Over the course of the semester I was assigned tasks to help develop a system test library that ensured the functionality of X-Rites products. I was also able to help with the testing and manufacturing of certain prototype products.

JR Automation Quoting Engineering

Preston

Major: Mechanical Engineering

My job was to prepare quotes for customers. This consisted of creating conceptual automated solutions for complex manufacturing problems, documenting and developing costing/internal budgets for each solution, and then presenting them in a professional and logical manner.

I was able to send over 20 quotes to potential customers over the course of the semester, and ended up winning contracts to produce 2 of them, which resulted in over 1 million dollars of business that was awarded to JR.

ME Co-op Experience

Robbie

Major: Mechanical Engineering

The tasks I completed ranged from design all the way to quality work. Bigger projects started out as design work, then milling the parts out myself or by the tool room, then assembly, troubleshoot, and install. Other tasks include being a member of a rust management team, designing parts for other machines, and helping troubleshoot other engineers machines.

Co-op at Altus

Michael

Major: Product Design and Manufacturing Engineering

As being the engineering co-op student at Altus, I have been given many responsibilities. I have tasks of creating and redesigning workstations so that the products could be assembled faster by our assemblers. I also deal with suppliers when there is a quality issue so that the issue does not occur again. I help with prototyping new products and I am including in discussions relating to the future of products and how we can develop our carts to be more successful. For being a co-op student, I have a lot of say in the development of our products.

Architectural / Building Mechanical Engineering

David

Major: Mechanical Engineering

I performed energy analysis for several buildings (Van Andel Institute, University of Cincinnati, and GVSU) to determine if any energy conservation measures (ECMs) could provide reduced energy costs. In some cases, the buildings are preexisting and the ECMs include adjustments and additions to older systems. In the case of a GVSU project in early design phase, building energy modeling provides useful insight for equipment selection and design strategies. Functional testing building automated systems is another task I was able to perform for Purdue's Active Learning Center. The testing consists of running the building's automated controls systems through all modes of operation to ensure systems will function as designed under all conditions (time, thermal loading, seasonal, etc)

Read More About Architectural / Building Mechanical Engineering

Co-op II

Joseph

Major: Electrical Engineering

I assisted in the plant electronics lab, doing what ever needed to be done at the given moment. I repaired and built mobile product test unit for our production floor and customers (shown in the experience submission picture). I performed ESD testing to help design a board layout change. I developed test masters for the end of the line test stations. I also conducted failure analysis of warranty returned parts as well as managed some maintenance improvements in the lab itself.

Gaining Automation Experience

Matthew

Major: Electrical Engineering

Throughout this second co-op rotation, I was tasked with many new responsibilities that I didn't get to do on my first rotation. These responsibilities included designing and implementing a Human Machine Interface (HMI), establishing communication to the machine's components via various communication protocols, setting up the machine's diagnostic settings, and programming the machine. I was also involved enough in a project to leave the plant and help out with the installation and debug process on the customer site.

GVSU Intern

Bryce

Major: Mechanical Engineering

At Magna Mirrors, I worked this semester alongside several engineers in the outside mirrors group at the Kentwood location. During my internship I was involved in a large amount of projects including disassembling parts for benchmarking, finding the output torque both manually and electrically of glass actuators, finding current draws of power fold actuators in different humidity and temperature settings, taking mirrors out for a drive in different test vehicles with accelerometers attached for vibration data, and creating special wire harnesses to allow serial control of a mirror to emulate a car control module. I also operated CNC mills to rework parts, did draft analysis of several mirror assemblies, coordinated part delivery between nearby plants, assembled prototype mirrors for customers, performed door slam simulations, and even conducted a case study at a nearby car dealership to find correlation between VIN numbers and the mirror combinations that are associated with them. I never expected such a small component of a car to have such a diverse array of processes and tests for an engineer to be involved in, but the outside mirror is an ever-evolving piece of technology that I have had the ability to become quite familiar with.

Western Michigan University

Megan

Major: Sport Management

- Executed all aspects of video operations including film breakdown, game capture, and live coding using SportsCode and Synergy Video programs

- Utilized Scoutware program to input recruits and maintain database

- Created mailouts and organized the distribution to potential recruits

EMC Co-op Second Rotation

Daniel

Major: Electrical Engineering

During the second rotation of the co-op, I worked with clients to run a variety of test such as Radiated Emissions (RE), Conducted Emissions (CE), Bulk Current Injection (BCI), Radiated Immunity (RI), and Electrostatic Discharge (ESD). Compared to the first rotation, I was a lot more independent working with client's to perform these tests. I also worked on the diagnostic aspect of the products to understand how the product circuitry was producing failures and how to reduce these failures.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.