Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Magna Co-op

Danijel

Major: Mechanical Engineering

At the location here at Kraft we do a lot of testing to meet environmental, mechanical, and safety requirements desired by the customers. I would perform many of these tests for the engineers and the projects they have with the customers to directly determine data of the mirrors' characteristics, and whether or not design changes need to happen. I would also do plenty of design work, from designing custom fixtures or adapters for the part I would need to test them, to gathering any other data when viewing designs in CAD.

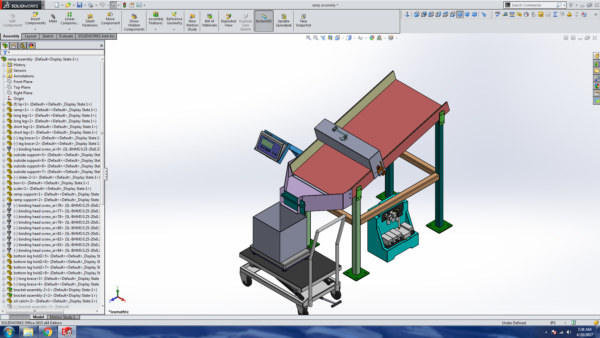

The Structural Concepts Experience

Joseph

Major: Mechanical Engineering

The most common task was changing the bill of materials on part assemblies as well as changing the respective models of these assemblies to represent the changes. Sometimes an entirely new part had to be designed in SolidWorks to satisfy the need of a part on the final product or assembly. For example if the part was made out of sheet metal, the SolidWorks model would be cut out on a CNC laser and then bent to shape.

Gentex Co-op

Dalton

Major: Mechanical Engineering

While at Gentex, I worked along side the process engineers in the final assembly area. Their job is to assemble all of the mirror components to create the final product. When arriving at Gentex, my group was in the process of implementing a new production line for Full Display Mirrors. My first project was to fully assembly and install three conveyor belts for the production line. I had to utilize my hands on skills and knowledge of Solidworks to complete my tasks. As the internship progressed, I received many task for improving the existing machine designs for the line. These improvements included designing and finding locations for brackets and flow racks. I also got some experience with selecting and testing new sensors for improving the build process.

Controls Intern summer

Brian

Major: Mechanical Engineering

Most of the tasks I worked on was data logging. For nearly every project in my business unit I would update the build's schematic which had changes made on paper but had yet to be updated electronically. When I wasn't updating schematics I was programming robots, designing user interface screens, and completing documentation for the company.

First Year Co-op Experience

Bruce

Major: Mechanical Engineering

The project that took up most of my time throughout the semester was a competitive review project. The purpose was to take competitors products, test the units, tear them down to see what was inside, and report on the findings and results.

I also was involved in a little bit of product enhancement projects as well as various testing that needed to be done.

JR Automation Co-op Experience

Johnathan

Major: Mechanical Engineering

For my first co-op rotation I was assigned to quoting. Companies looking for automated manufacturing solutions send JR Automation a "request for quote" document that outlines the requirements and specifications of the machine they would like us to provide them. I was assigned many quotes during my co-op semester. The tasks associated with these quotes included developing a concept and cost for the potential machine to be designed and built. This required contacting vendors for large components of the machine and meeting with our internal engineers to build on past experience.

Engineering co-op

Megan

Major: Mechanical Engineering

As an intern doing my first semester of co-op, I did training and orientation for about a month. The tasks I did after that started out as fairly simple design projects, but gradually became more complex and I was given more responsibility.

Mechanical Engineering Intern

Chad

Major: Mechanical Engineering

My tasks often revolved around continuous improvement of Genesis' production processes. This has provided me with projects that vary largely in scope and purpose. I have spent some time doing time studies to see where time is lost or there is some inefficiency and how the process could be enhanced or changed to make it more efficient and quicker if possible. I have spent some time designing and fabricating carts or racks to hold materials, parts, or finished products. As the semester progressed, I was given more complicated projects to work on. A couple of those more complex projects were fixtures that are actually part of one of Genesis' new productions cells and they are to help make the process more efficient.

Dematic Co-Op I

Tanner

Major: Mechanical Engineering

During my time at Dematic I have worked on a wide variety of engineering tasks. I work primarily on the Walmart Mechanical Engineering team which focuses on the design of conveying and sortation systems for Walmart Distribution Centers. I have also had the opportunity to work on the Amazon Mechanical Engineering team which specializes in the design of conveying and sortation systems for Amazon Fulfillment Centers. My responsibilities at Dematic have been diverse. The majority of my time is spent on AutoCAD and Maestro, two of Dematic's primary CAD programs. Using these programs I spend time developing and updating drawings. I have worked on system layout drawings which describe the system's design in detail, and have also worked on installation drawings. These installation drawings are sent to Dematic's installation teams on jobsites to guide them through the installation process of the new systems. I have also spent time assisting lead project engineers with their project needs.

Co-op Rotation 1 at SAF-Holland

Erich

Major: Mechanical Engineering

I aided in a research project to develop the best steel coating in the industry; made conceptual designs for a potential new product; design changes to current products; learned to weld and plasma cut, among many other things, working in the test lab; and lead tests on my own. All the work I did was meaningful; it was never busywork.

2017 First Engineering Co-op

Anthony

Major: Mechanical Engineering

I worked on creating 3D graphics for the Hydronic and Air Handler system's controls we implemented as an interface for the customer we were working for. This way they could easily monitor their equipment from one central site without it being confusing.

ME 2017 First Coop

Tim

Major: Mechanical Engineering

Primary projects i worked on were two innovation projects, some quality testing for various programs, and a wide variety of miscellaneous non-PDP development.

Arconic (APP) - 2nd Rotation

Clark

Major: Mechanical Engineering

I worked in the Research & Development department, so my range of tasks was diverse. As a mechanical engineer I got to design bucket elevators, guarding, fixtures, and several small projects along the way. I was also involved in some small automation projects and was introduced to robots and the logic behind them.

EGR 390

Jake

Major: Mechanical Engineering

I am a design engineer, so I create drawings and models of filter presses according to the customer's selected options. Occasionally I will help out with creating aftermarket retrofits to competitors products.

Dematic Co-Op II

Zach

Major: Mechanical Engineering

While at Dematic, I have completed a wide variety of engineering tasks. I work on the Amazon Mechanical Engineering team which designs conveying and sortation systems for Amazon Fulfillment Centers. My day-to-day functions include making/updating drawings in AutoCAD. These drawings are sent to installation teams on the jobsite to aid in the installation of conveying systems. I also order parts that may have been missed or ordered incorrectly during primary order entry.

Trans-Matic Engineering Co-op

Sam

Major: Mechanical Engineering

Working as an intern for the engineering department I completed a wide range of tasks. Like my last semester, I handled a lot of updating and redesigning existing tooling in the presses. Each production job has tooling originally designed that fits into the presses to produce specific features on the part. These designs go through constant changes as the tools wear down or industry standards change. This was all done using the latest version of Creo (3D CAD software). Besides just redesigning existing tooling I got to work with other designers on twelve new tooling jobs, and was able to take a lead role on two other new tooling designs. I also handled the design work for all gauges and managed engineering drawings for the product launches.

JR Automation Quoting Engineering

Preston

Major: Mechanical Engineering

My job was to prepare quotes for customers. This consisted of creating conceptual automated solutions for complex manufacturing problems, documenting and developing costing/internal budgets for each solution, and then presenting them in a professional and logical manner.

I was able to send over 20 quotes to potential customers over the course of the semester, and ended up winning contracts to produce 2 of them, which resulted in over 1 million dollars of business that was awarded to JR.

ME Co-op Experience

Robbie

Major: Mechanical Engineering

The tasks I completed ranged from design all the way to quality work. Bigger projects started out as design work, then milling the parts out myself or by the tool room, then assembly, troubleshoot, and install. Other tasks include being a member of a rust management team, designing parts for other machines, and helping troubleshoot other engineers machines.

Architectural / Building Mechanical Engineering

David

Major: Mechanical Engineering

I performed energy analysis for several buildings (Van Andel Institute, University of Cincinnati, and GVSU) to determine if any energy conservation measures (ECMs) could provide reduced energy costs. In some cases, the buildings are preexisting and the ECMs include adjustments and additions to older systems. In the case of a GVSU project in early design phase, building energy modeling provides useful insight for equipment selection and design strategies. Functional testing building automated systems is another task I was able to perform for Purdue's Active Learning Center. The testing consists of running the building's automated controls systems through all modes of operation to ensure systems will function as designed under all conditions (time, thermal loading, seasonal, etc)

Read More About Architectural / Building Mechanical Engineering

GVSU Intern

Bryce

Major: Mechanical Engineering

At Magna Mirrors, I worked this semester alongside several engineers in the outside mirrors group at the Kentwood location. During my internship I was involved in a large amount of projects including disassembling parts for benchmarking, finding the output torque both manually and electrically of glass actuators, finding current draws of power fold actuators in different humidity and temperature settings, taking mirrors out for a drive in different test vehicles with accelerometers attached for vibration data, and creating special wire harnesses to allow serial control of a mirror to emulate a car control module. I also operated CNC mills to rework parts, did draft analysis of several mirror assemblies, coordinated part delivery between nearby plants, assembled prototype mirrors for customers, performed door slam simulations, and even conducted a case study at a nearby car dealership to find correlation between VIN numbers and the mirror combinations that are associated with them. I never expected such a small component of a car to have such a diverse array of processes and tests for an engineer to be involved in, but the outside mirror is an ever-evolving piece of technology that I have had the ability to become quite familiar with.

2nd Co-op Rotation

Michael

Major: Mechanical Engineering

I was in the design Department this semester and enjoyed it. I dimensioned part drawing, checked other designers work, and designed a few components of my own for various machine cells.

Co-op 2 at Autocam

Joseph

Major: Mechanical Engineering

I performed studies to analyze the capability of an automated inspection machine. I adjusted hardware in the inspection machine so that the machine's measurements correlated more closely with machinists' gages. I analyzed inspection data to identify unnecessary dimensional inspections for certain part models, removed these inspections, and saved 85 inspection hours per week. I updated the Autonomous Maintenance Logs for around 30 machines to a format that is more user-friendly and easier for machinists to keep track of the maintenance that is being performed. I updated a wash process for a high-volume part and increased throughput by 800%. The primary benefit of this wash improvement was 25 hours per week in labor savings due to the parts getting cleaner. I performed tests and improved the wash processes of other parts as well. I performed studies for a new cutting tool that should save about $30,000 annually in rejected parts. I designed devices to improve process efficiency and provide a more ergonomic working environment for employees. I introduced high school and early college students to Autocam through facility tours and presentations.

Small Company, Big Impact

Bridget

Major: Mechanical Engineering

Writing protocols and reports for fixture installation qualifications. Working in the clean room with other engineers to determine new manufacturing processes.

Doing annual fixture calibrations. Was project manager for three small projects.

Cascade Engineering Co-op II

Sara

Major: Mechanical Engineering

I worked with a prototype technician and together we assembled over 500 dashmat prototype parts. This involved some manipulation of plastic injection molded dashmats and assembly of the parts with fiber pads. I also performed a more thorough study and analysis on my dead pedal weight reduction project from the previous co-op semester. Finally, I was involved in the acoustical testing of various fiber pads and the development of a new dashmat we plan to pitch to a potential client.

Co-Op at L3

Mowgli

Major: Mechanical Engineering

I worked as a mechanical engineer responsible for the testing and analysis of transmission components to determine how our current components compare to our proposed improvements.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.