Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Signal integrity / Power integrity Co-op Experience

Ian

Major: Electrical Engineering

As a SIPI co-op student, I performed time-domain and frequency-domain measurements on customer products. I also performed EMC pre-compliance testing on customer products, as well as networked and discussed various engineering topics with customers.

Read More About Signal integrity / Power integrity Co-op Experience

EGR390 Experience

Jake

Major: Electrical Engineering

I completed multiple cable drawing packages that interface between our completed automated test stations to both flight data recorder products and displays. I also completed electrical schematics and a printed circuit board design for a cable tester completed new product that has its own printed circuit board inside of the cable. In between working on projects, I spent my time sustaining production test stations which include 3-axis robots and outdated hands-on electronic test fixtures.

JR Automation Control Engineering Co-op

Ryan

Major: Electrical Engineering

As a controls engineering, I am responsible for programming these machines using PLCs (Programmable logic controllers, and HMIs (Human Machine Interfaces). Other responsibilities include using AutoCAD Electrical to design and update machine electrical documentation.

2nd Co-op Rotation

Yougourthene

Major: Electrical Engineering

I was tasked to redesign and build a device that tests the different functions of the Ford Bronco tail lamp. Another project that I worked on consisted of designing a smart lamp, which is a lamp with an additional circuit that will modify its functioning by simulating individual failures of the LEDs sequentially. The smart lamp is used to check if the equipment could detect the failures. I also did a lot of troubleshooting of failed lamps to determine the exact cause of the failure and then documented the findings in a report.

The life in High Speeds

Nicholas

Major: Electrical Engineering

Tasks ranged from troubleshooting preproduction parts to running simulations of circuit boards. It also entailed working with clients from Fortune 500 companies to small entities like our organization.

Peter Basso Experience

Joseph

Major: Electrical Engineering

I have designed lighting systems for buildings. I have helped in research on emergency generators. I have designed the layout of receptacles for office spaces. Lastly, I learned how to the use Revit, CAD and AFI.

EGR 490 Co-op 3rd Rotation

Megan

Major: Electrical Engineering

During my 3rd rotation, my tasks included writing test reports, testing products for pre-compliance emissions, immunity and transients, communicating results to customers, and performing diagnostics on non-compliant projects.

Electrical Engineering @ aMDI

Renzo

Major: Electrical Engineering

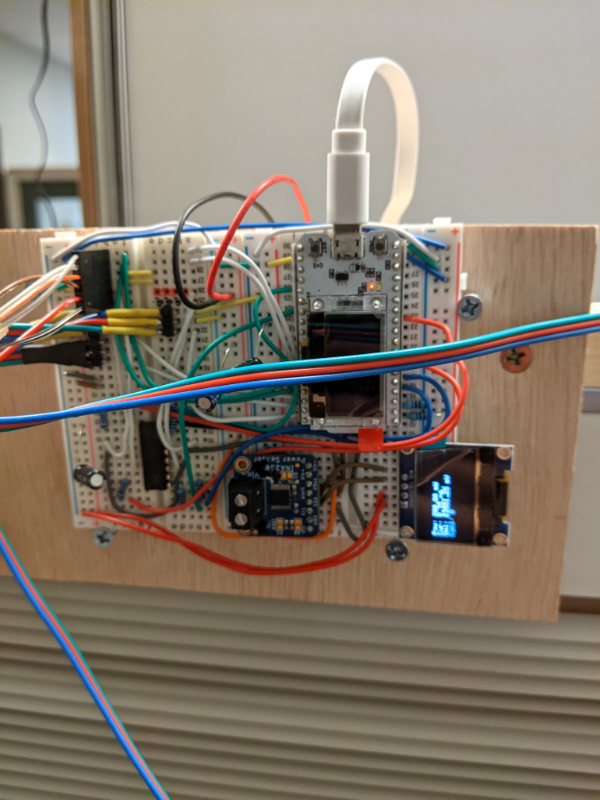

This semester I was able to develop an attachment for the sensor package EmotiBit. This package contains a variety of sensors containing photoplethysmography, thermistors, electrodermal activity, accelerometer, gyroscope, magnetometer, etc.

This attachment helps visualize all the data without the need for wifi/Bluetooth. A variety of approaches were used to calculate Heart Rate, Heart Rate Variability, and Oxygen Saturation with the available data.

Co-op Rotation 3_ODL Inc.

Joshua

Major: Electrical Engineering

The projects I completed this year was creating a information matrix for all of the electrical equipment we use in our three plants. I also calculated the power used from the mains all the way down to the outlets.

My first co-op rotation at Nissan

Stephen

Major: Electrical Engineering

During my term I validated electric car chargers for current production vehicles, and performed a benchmark analysis of many competitors vehicles and their high voltage battery systems. I also synthesized weekly reports and presentation material. Data analysis was a huge portion of my job, so I often used MATLAB and excel.

2021 Co-op Experience First Rotation

Zachary

Major: Electrical Engineering

The tasks that I was assigned this semester included understanding the design of constructing a building electrically. This includes designing new and existing power, lighting and fire alarm in a three dimensional CAD software. I was also tasked with coordinating across different disciplines to ensure that the project design is moving at a great pace between disciplines. It really helps the project design when disciplines are on the same pace, and this ensures that the client would be not only satisfied, but excited about the outcome of the project. I also was tasked with understanding the phasing of the design of a project, and why each project goes through different phases.

E3 Compliance Co op First Rotation

Nicholas

Major: Electrical Engineering

I have performed numerous EMC tests from a wide range of products from aviation to commercial household equipment. I also helped diagnose issue with certain products and developed solutions to make these products pass test standards or simply prototyping stages.

Koops Project Engineer Co-op

Zachary

Major: Electrical Engineering

Over the course of my PE rotation I worked to debug a line of machines all made for one customer. This involved finding problems with the already assembled machines, looking for the best and most sensible solution for each problem, and then carrying out said solution. One problem with interference between two moving parts could be grinding off excess material, while another problem of a sensor not functioning could be a miss wired connection. These problems often take on the spot problem solving to find and fix, and making a machine work when it wasn't is a satisfying feeling.

Electrical Engineering at ODL

Joshua

Major: Electrical Engineering

While at ODL I was able to design and help use a force/position tester. I was the one that made the software for the tests and helped pick the hardware. I also established Altium at ODL and was able to start designing PCBs for ODL. I was also able to make different test codes and data analysis for the different tests we were running.

Shape Corp: Thinkers, Believers, Doers.

Chau

Major: Electrical Engineering

The majority of my responsibilities were split into two categories: continues improvement and maintenance. The continues improvement was an on-going project where I was responsible for designing, programming to upgrade the functionalities on all the roll-former systems, welding robot, or deburring system to improve the production processing. The main goal was to reduce the time needed to manufacture parts but still keep the product at high-end quality. On the other hand, maintenance was the work requests from other areas of the company to support production.

Engineering Co-Op 1 at E3 Compliance

Megan

Major: Electrical Engineering

I personally completed several different EMC tests for commercial, medical and automotive products to help get them out on the shelves and being used in important everyday applications. These tests also included generated reports full of information which is sent to the customer. I also completed several documents, including work instructions, test setup instructions and materials lists to make things easier and more organized/streamlined in the lab.

Winter 2021 Co-op Experience

Joshua

Major: Electrical Engineering

I mainly focused on software engineering throughout my co-op this winter. I was involved in our most recent mega project Urban outfitters. I re-wrote multiple high speed sorter divert function blocks and converted them from STL to SCL. This was done because the PLCs used in projects were upgraded from the Siemens 300 PLC to the Siemens 1500 PLC. I also built the visualization and PLC software for two empty tote buffer stacker and destacker systems. On top of this I engineered the added value high speed sorter loop.

Twisthink Electrical Engineering Co-Op

Sarah

Major: Electrical Engineering

While at Twisthink, I was given the opportunity to work on a program for an embedded system through CCS. I was also able to work on debugging circuits on manufactured circuit boards. I was also able to redesign an existing circuit so that it could be recreated using a new software. These tasks were extremely interesting as they all built on my existing knowledge from classes, but pushed me to learn and do more with that knowledge.

Co-op Rotation II

Andrew

Major: Electrical Engineering

I worked in the notching department of the battery making process. I helped keep machines running at their highest capabilities through various troubleshooting and permanent upgrades. I had a focus on reducing scrap which would positively impact our yield. I helped implement the ability to rework material that would otherwise have been scrap for in the notching process. This is the first time in LG ES Michigan that we were able to rework material in notching.

JR Automation - 2nd Rotation

Hannah

Major: Electrical Engineering

I was assigned to one main project this semester that allowed me more individual responsibility, while still having a mentor to guide me. I was able to help through the debug process of the machine which included updating HMI screens, PLC programs, and teaching points for robots.

Herman Miller Co Op - Design For The Good Of Humankind

Xue Hua

Major: Electrical Engineering

The majority of my responsibilities were split into two categories: The Database Project and Work Orders. The Database Project was an 8-month project where I was responsible for programming, designing, testing, and implementing an asset management system. This system would be used by the entire Controls Department at Herman Miller. The specifications included vigorous querying needs, functionality to interact with the data, and an intuitive user experience. The goal was to manufacture an asset management system where the entire Controls Department could manage its internal assets and its various details and information such as IP information. On the other hand, Work Orders were work requests from other areas of the company to support production. The one I enjoyed most was implementing a sensor to detect the edge of a panel to eliminate a design error. This work order was on the back burner for around a year before it came to me. It was a 3-month project where I had to research sensors, calibrate them precisely and implement them into the existing PLC program. This specific was project was a success and the steps I laid out were administered to 7 other machines. This was an example of a typical work order.

Read More About Herman Miller Co Op - Design For The Good Of Humankind

L3Harris - 3rd Rotation Co-Op

Michael

Major: Electrical Engineering

Throughout the semester, I worked on a lot of different projects that involved things such as library development, program verification, and hardware maintenance and repairs. Most of the time spent during this semester was dedicated to writing the testing program that will be used for an upcoming product, which I was primarily responsible for.

Final Rotation at Phase 1 Engineering

Andrew

Major: Electrical Engineering

During my third co-op rotation, I designed and built a test fixture used to test multiple device radio communication. I aided in the analysis of the data collected with this test fixture.

Performed medical grade stainless steel welding on an expensive RF prototype.

Upgraded existing testing module prototype to have use a stepper motor. Wrote controller code and installed stepper motor in place of existing motor configuration.

Aided in the design and development of a photo-voltaic solar harvester for use in energy intake analysis. Built and tested all working prototypes. Created data analysis tool using java to store data in the database and then analyze data based upon user input parameters.

Performed data collection with Thermo-Electric generators to determine energy output versus temperature drop across several devices.

3rd Rotation at Innotec

Cameron

Major: Electrical Engineering

I completed a variety of projects this rotation. For example, I completed process improvement projects such as machining steel fixtures to improve automation, improving quality check reliability by performing simple worst case circuit analysis, designing 3D prints for machine fixtures, implemented a data logging feature on a production line, and more. I was given the monthly responsibility of 5S for my team, which involves streamlining everyday tasks such that the team operates in a ýleaný manufacturing environment.

Dematic - Rotation III

Aleksandr

Major: Electrical Engineering

I was put on a project and I was working on controls layouts for most of my rotation. This involves placing devices on the conveyor, routing power cables, routing network cables, and then creating layout drawings for required views (power bus, networks, devices). I also spent some time during my last couple of weeks training/guiding a new engineer through the entire process of creating the controls drawings (including using the software the company uses) so that once I left he would have the knowledge and skills to work on an area on his own.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.