Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Sport Internship at the YMCA

Stephen

Major: Sport Management

I was in charge of the setup and tear down of equipment for both the youth and men's basketball league, as well as managing the scorekeepers and referees during the games. I also assisted in running a free baseball league for the innercity kids of Grand Rapids, MI. My tasks were to attract clients, data entry, manage equipment and uniforms, collect gloves from the glove drive, manage the coaches and umpires, and to follow the state's regulations while passing out free meals to the kids after the games.

Trane Grand Rapids Graphic's Experience

Tyler

Major: Mechanical Engineering

At Trane Grand Rapids, I was responsible for drawing their floor, hydronic, and air handler graphics using Photoshop. Using floor and mechanical plans, I drew 2-D graphics their customers use to control their HVAC system and what the technicians use to easily fix any issues. I put together graphics orders by going through mechanical plans and control submittals and sent the order to their centralized graphics team.

Intern project

Reuben

Major: Mechanical Engineering

I created work instructions, performed team member training, data analysis, and product development. I worked extensively with a team to develop a product rationalization process - meaning, how to wisely determine which products to discontinue producing.

Super Hands-on

Zachary

Major: Mechanical Engineering

As an intern/cop-op student working with the Innovation team, my job as long as the other engineers job's on the Innovation team was to find any and all ways to improve the manufacturing processes throughout the shop. Whether that be deciding where to put a new machine or relocate a current machine, to designing milling fixtures for various parts, or designing new systems or parts to be used around the shop. I was tasked with a job in pretty much every aspect of the shop. I designed and fabricated a new cart that holds hooks for the powder coating line, designed 7-8 milling fixtures for the automated CNC milling cell, to running a time study and analysis looking at the laser cutting and press braking processes.

First rotation at DornerWorks

Kendra

Major: Computer Engineering

I worked on developing automated hardware tests for a prosthetic elbow. This included writing unit tests to cover as much of the existing manual test protocol as possible and adding hardware to the existing test fixture.

DornerWorks EE Co-Op

Jonathan

Major: Electrical Engineering

I worked on a project at DornerWorks for Traeger Grills and was involved in many facets of the project including performance testing and data compilation of grill temperature and pellet level sensing. As a result performance enhancement I worked on were integrated into the grills firmware. I also worked on integration testing by developing a schematic and laying out a test simulation PCB. Part of the function of the test simulation board was to simulate a thermocouple for the integration tests to run grill cycles. I also gained experience setting up flashing of the on-board microcontroller and had opportunities for developing embedded software.

- IT

Creating scripts to help automate quarterly updates. These included creating a list of wiki pages without backlinks, creating a list of unused licenses, and creating websites to aid in cleaning up company repositories. Small tasks included help with NIST documentation, creating a widget to help track equipment on the IT Helpdesk website, and documenting my own work on the wiki.

First Steps

George

Major: Computer Engineering

I worked on writing unit test, feature testing, debugging, small feature updates for our Analytics software, and database scripts. I wrote guides for setting up third part vision systems with our software and troubleshooting guides for when communication errors occur.

I also worked with a customer to install and periodically update our software.

Engineering Co-Op Rotation One at Motion Mechanics LLC

Dylan

Major: Mechanical Engineering

This semester I was able to design, build and test. I designed various mounts for a company that we developed a front mount blower for. These mounts adapted to various z-Turn mowers and golf course vehicles. I also was able to go through a prototype build of a floor scrubber and do a lot of validation testing. Whether it was developing mounts or building the scrubbers I was able to do a lot of testing and troubleshooting.

Read More About Engineering Co-Op Rotation One at Motion Mechanics LLC

Machine Design Co-op 1

Bryanna

Major: Mechanical Engineering

For this rotation, I handled smaller work orders coming from the manufacturing engineers at different facilities to the Machine Tool Services team that I was working on. These work orders involved using CAD programs to design small assemblies or adding to larger ones to solve issues that we were seeing on the assembly lines. I also took on all 3D print orders, many of which were used as prototypes to test designs. I took on a few longer term projects both of which involved in the automation of an entire assembly line for one of our most popular products. I was tasked with two projects within the automation project that will be used in the automated assembly line. Also at Herman Miller, as a summer intern, you are placed in a group of about 9 other interns, all from different fields of study, and tasked with a large project sponsored by someone higher up in the company. My group was given a sales and operational planning project, of which I knew very little of the topic. We met 1-2 times a week meeting with each other or with operational managers from all of our manufacturing sites in West Michigan. The project was meant to find the capacity constraints of each product lines, what would be required to do to add about 30% capacity to each of the lines, and to find issues within the supply chain. At the end of the summer, we were to present our information to our sponsors and whoever else joined us.

Summer Co-op

Josephine

Major: Mechanical Engineering

I worked as an ME and I drew up parts for machines. Everything was done in Solidworks. Sometimes I was working on modifications for existing machines, other times I was working on new machines. The last part of my time I was an unassigned resource and was able to work with a lot of different people and departments.

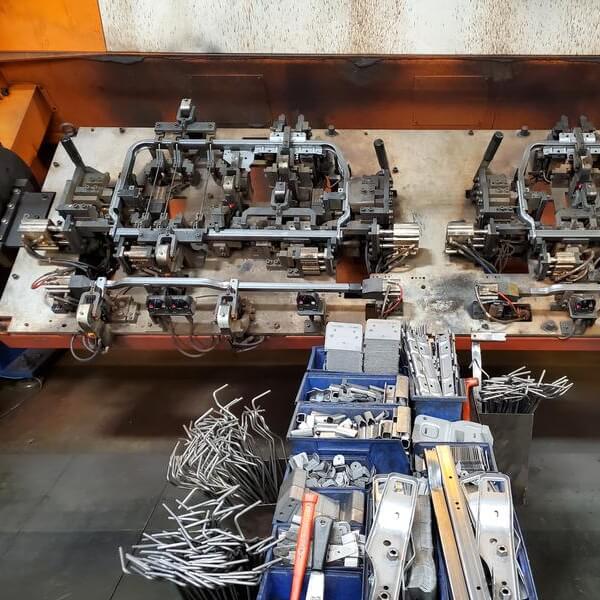

Innotec Co-op

Cameron

Major: Electrical Engineering

I was responsible for kicking-off tooling designs, testing and verifying tools, lean process organization, and many other projects. All summer I was assisting in 6 product and process launches where I recorded data, made tooling upgrades, machined tools and helped run production. I was Also part of an intern team that reduced the scrap in our division by 5% through analysis, determining root causes, and implementing process changes.

Controls Engineering Co-op I

Aleksandr

Major: Electrical Engineering

I completed several small tasks which consisted of making device labels to go on controls devices and I also made a commissioning checklist for a project. Then I went to a customer site where I helped commission a line that was being added to a system. I was given a small project to do where I had to go through the entire process that a controls engineer would go through to complete a project. This consisted of creating an entire drawing set showing all the devices, networks, and power buses for a cabinet. I had to have technical reviews with a principle engineer to go over the drawings I created. I also had to write a Discription of Operations document and then I had to write the PLC program for the line.

Mechanical Engineering Co-op

Austin

Major: Mechanical Engineering

During my co-op, I worked on a range of projects dealing with robotic welding cells used for the assembly of auto seat frames. My work was mainly focused on the fixtures that the seat assemblies are welded in, modifying components or creating new ones using SolidWorks to help save money, meet new customer requirements, or increase quality of life for operators.

First co-op rotation at Autocam Medical

Zachry

Major: Product Design and Manufacturing Engineering

I came into this co-op with four years of previous machining experience. My role this semester was somewhere between a skilled machinist and an engineer. I worked on a team to help design a process for a new product. This included writing CNC code, testing process capabilities, programming CMMs and other gauging devices and many more things. I worked closely with my team to get the process stable and repeatable on one machine with only one machinist (myself) and then was able to expand our process to four machines and train six machinists on it by the end of the semester.

JR Automation

Ethan

Major: Electrical Engineering

For most of the semester I worked on one really big project. I was with it from pretty much start to end and got to see it go through all it's phases. I helped out with everything from debugging the code to making drawings.

Herman Miller Co-op 1

Chase

Major: Product Design and Manufacturing Engineering

Some of the projects I worked on varied from designing conveyor components, to overseeing part re-routing on the floor, to data collection and interpretation. All of which included working with many different people throughout the company. I was also put on a group project with some of the other interns where we worked on a presentation all summer and reported out at the end.

Co-op Summer at Herman Miller

Samantha

Major: Product Design and Manufacturing Engineering

This summer I was apart of the options team, which is responsible for making custom modifications to any Herman Miller design. I had the opportunity to engineer real products and actively contribute to my team. Furthermore, I worked on an intern project team that explored the supply chain and identified bottlenecks in the system that are hindering us from increasing the capacity of certain product lines.

Controls Engineering Co-Op

Katey

Major: Electrical Engineering

This internship began with an assignment to use AutoCAD Electrical to design a practice print-package based on requirements from my supervisor. From there, I moved on to updating the companyýs AutoCAD Electrical title block and AutoCAD Electrical tutorials. I was then assigned the task of creating templates to increase the efficiency of the companyýs lock-out-tag-out documentation and bill of materials generation. These tasks formed the bulk of my semester. Furthermore, I was given the task of utilizing my templates on multiple customer jobs. Finally, I gained firsthand experience on the floor shadowing the companyýs electricians and familiarizing myself with the build stage of the engineering process.

Mechanical Engineering Co-Op -- 1st Rotation

Chad

Major: Mechanical Engineering

This summer I completed a number of design projects related to continuous improvement in existing production flow. My role was design heavy, which entailed primarily CAD design. It also involved meaningful interaction with engineers, hourly team members, and production support to arrive at appropriate solutions to existing production issues. In some instances, I was involved in machining my designs from scratch.

Read More About Mechanical Engineering Co-Op -- 1st Rotation

Living Logistics

Beau

Major: Mechanical Engineering

I was a systems engineer at TGW. Our primary task was to take everything that was visualized in the sales phase and bring those layouts to reality. Gathering quotes and going on site to measure and map building columns and floor flatness along with meeting with the customer to approve drawings was a large part of the responsibility. Making sure that the system that sales built was going to be able to meet rate and also fit in the building was a tough task because in the logistics industry rate is everything.

First Co-Op Rotation at Nissan

Jordyn

Major: Mechanical Engineering

I had three main objectives for the summer and had a few side projects. My first objective was to categorize warranty claims for primary failed parts (PFP) on specific models manufactured at different plants; my second objective was to analyze shape data and key feature diagrams to determine if there were any discrepancies in the PFPs between each plant and determine any solutions to reduce warranty claims on these PFPs. My third objective was not related to the first two, it was to benchmark universal garage door openers (UGDO), specifically Homelink, among different OEMs to improve and amend our own Homelink quick reference guide (QRG) and owner's manual (OM) to improve our JD Power customer survey scores. Some side tasks include attending 20 hours of Nissan training, giving an intern introduction presentation, plant visits, and intern activities.

Co-op at Transmatic

Avery

Major: Product Design and Manufacturing Engineering

I completed tasks ranging from simple updates of tooling drawings to updating and designing components for assembly machines and presses in the Holland location. I designed a condensation hood to catch fumes and run off coming from some of the presses, part diverters where operators can switch parts coming off the press from going in the good part bins and bad parts bins.

First Co-op Rotation with Innotec

Ryan

Major: Mechanical Engineering

The majority of my projects were geared toward machine improvement. This involved designing and assembling/installing components that solved an existing problem, or improved upon an original design. Some noteworthy projects include redesigning a part crowder assembly and designing an attachment that trims off excess material from parts.

In addition, I was also involved in a group intern project that helped to organize the material flow and layout of a new line.

The World of Embedded

Nicholas

Major: Computer Engineering

My first project since I've been here and the one I plan to see through it's entirety is a UV device meant to kill bacteria in hospital settings. I have done work with this project in almost all of its functional areas. I started working with the voice commands, testing the sensors and bulbs, testing distance and motion, and even soldering and doing EMC testing on the boards to test the device against radiation standards. That has been the project I have spent most of my time here with as well as the one I've done the most testing with. I have also been able to work alongside my co-workers in writing test software in C# (a new programming language for me up to this point) for a motor on conveyor systems as well as being able to write most of the test software by myself for a Radon Detector. I did a lot of testing with small beacons testing distance and motion as well as troubleshooting a remote control for a light that would be use in an Operating Room setting.

First Rotation, Engineering Co-Op

Nathan

Major: Mechanical Engineering

Over the course of this co-op rotation, I helped to facilitate the required maintenance and repair of a wide variety of industrial automotive manufacturing equipment.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.