Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

The Final Co-op

Ryan

Major: Electrical Engineering

Designed PLC and HMI programs for two projects, one project consisted of modifications to 3 air handling units and the other was the design of two new air handling units. I also went on a few commissioning trips (Indiana and Virginia) to aid in the commissioning and installation process for these projects.

Embedded Software Co-op at Gentex Corporation

Allen

Major: Computer Engineering

This semester, I worked on a new full display mirror (FDM) for an automotive customer. My typical tasks included discussing and implementing requirements for the mirror.

Specifically, I focused on the graphical user interface (GUI) and HomeLink features. The FDM is a very complex system with several modes - each of which must display its own set of graphics to the user. Some of the GUI features I implemented include pan/roll/tilt/zoom adjustment menus, HomeLink training instructions, and HomeLink activity graphics.

I also focused on other implementation details of the FDM including power modes (battery support) and peripheral management.

Read More About Embedded Software Co-op at Gentex Corporation

Software and Hardware Development

Kelly

Major: Electrical Engineering

This semester I got to dive a bit into hardware development. I helped design and prototype a dongle that will be used by Amway. This dongle communicates with existing water and air filters, and technicians will use it to debug issues for customers whom own these devices. In addition, I worked on software development in Python and C for a missile systems project. I also began to gain more FPGA experience through other tasks I was assigned.

Innovation

Connor

Major: Product Design and Manufacturing Engineering

As an advanced product design intern I work mostly on benchmarking and assisting other engineers. Benchmarking consists of taking competitors mirrors and creating a document that breaks down competitors mirrors performance and parts. Another huge part of working in the Advanced Product Development group is our quarterly innovation meetings. Each quarter we are tasks with prototyping a new feature or product that has never been done before and presenting it to the team.

Co-op 3

Bradley

Major: Product Design and Manufacturing Engineering

My job during this internship was to play the role of a test and measurement mechanical engineer. This role involved designing fixtures, custom parts, and machines in CAD to improve the efficiency of test and measurement stations on specific assembly lines in all departments around the company. After a design solution was generated, it was also my job to send out the fabricated parts and purchase the necessary purchased parts. This involved the creation of a professional Bill of Materials as well as budget planning to justify certain solutions. Once that project was fully fabricated, it was also my job to assemble and wire the solution. This allowed me to spot mistakes and learn better ways to design machines and fixtures in the future.

Holland BPW

Chad

Major: Computer Engineering

This semester, aside from my day to day maintenance and duties, I had two big projects. One project was an enterprise wide wi-fi upgrade. The other project was a proof of concept software defined network where I worked with an external company.

Cybersecurity Co-Op

Evan

Major: Computer Engineering

I performed a large variety of project during my co-op but they all boiled down to one goal, evaluate the overall security posture for an organization. This included performing technical reviews such as penetration tests for a company's internal and external presence as well as policy and procedure reviews. These tasks included a lot of travel due to performing most of these assessments from the client's location. I was able to travel across the U.S. but many people from the firm travel all around the world.

Header and Hanger

Tyler

Major: Mechanical Engineering

This semester I was assigned with a senior engineer on a specific project. He put me in charge of designing a header and hanger system. This system supports conveyor by suspending them from the ceiling. This allows for additional conveyor to run underneath. The goal was to design components that will safely hold the conveyor with the maximum conveyed load. Part drawings were made and sent to fabricators to make the necessary components. Installation drawings were made with labels for the correct parts and dimensions to tell mechanical installers where to put the components in the building. Finally, assembly drawings were made to show the installers how to put the components together.

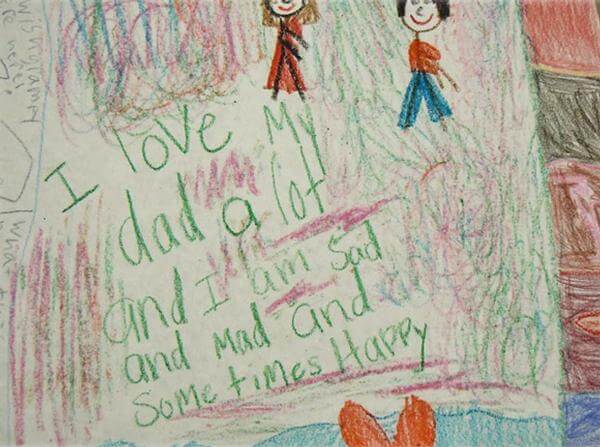

Ele's Place Internship

Ashley

Major: Health Communication

I completed media releases, social media calendar, designed invitations and save the dates, collected donations and helped organize a festival, created an updated media contact list and designed new handouts and newsletters.

Co-op #3 The Final Twist

Christopher

Major: Electrical Engineering

In my previous semesters, I had the ability to work on numerous projects for different West Michigan companies where I learned a lot of valuable skills. However, this semester I had a very narrow focus on a single vision system project. This project included camera evaluation and testing, data set development, and transfer learning algorithms. I was able to utilize a variety of tools in order to complete this project including MATLAB, python-based scripts, TensorFlow and Google's machine learning engine.

Farming Girl

Jessica

Major: Advertising & Public Relations

I worked on the farm in all aspects including day to day work, Tuesday Harvests, and Wednesday Markets. I also worked on creating content for Instagram and day to day posts. I also worked on a special project that posted every Thursday. This project was a recipe a week. I used the veggies and some fruits in a way that some people may not have thought about. In a bonus there were many times that the veggies were grown on the SAP farm.

Controls Engineering Co-op at

Kyler

Major: Electrical Engineering

My day-to-day tasks consisted of hardware and software design for various machines. Projects that I was involved with included a laser marking machine, a pin-stamping poka-yoke machine, robot end-of-arm-tooling configuration, and a rod crimping machine to name a few. I worked on PLC programs, electrical schematic drawings, and also completed standard documentation for all of the machines along with research and development for upcoming projects.

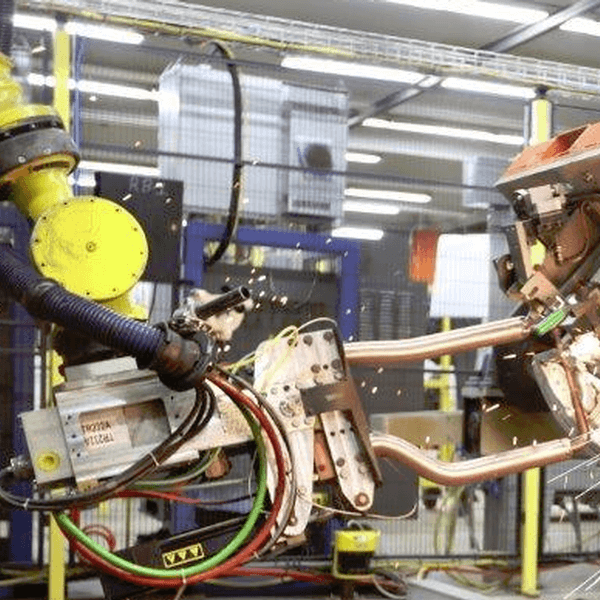

JR Automation - 3rd Rotation

Natalie

Major: Electrical Engineering

In my third rotation, I was given a lot of individual responsibility. I got the opportunity to write programs as well as teach routes and points for material handling robots. This is what moves parts through the cell to get the automation moving. I also got to create HMI (Human Machine Interface) screens so that operators can interact with the cell. On top of that I got to write logic for the actual operation of the machine and assist with design decisions to best suit the customer's needs.

Controls Programming At Koops

Max

Major: Mechanical Engineering

The projects I was given were PLC based, which is programming via ladder logic. A task given to me was to offline code machines; this is creating the general structure of the machine and how it processes inputs and outputs. Another task of a controls engineer at Koops is to debug machines, which required working with the PLC and the hardware of a machine to create create an operational PLC.

Open doors to a Bright future

Luis Enrique

Major: Mechanical Engineering

In my time at Axis, I wanted to be part of the different department along with my three co-op rotations. My first semester with them I was mainly working on the factory floor with the workers and reporting directly to one of the project managers. On my second rotation, y was part of the Design department, this is where I wanted to stay the most time since the work was more interesting and the relation between the designers, factory floor workers, project managers, and customers was interconnected. Basically, I was able to know what was going on everywhere and suggest changes to anything.

This is where I found the most interest inside the company other from the project manager position that I wanted to be part of, but this was not possible since a project on the automation industry could take more than 1 constant year of work and I was just there 1 semester at a time making this opportunity almost impossible.

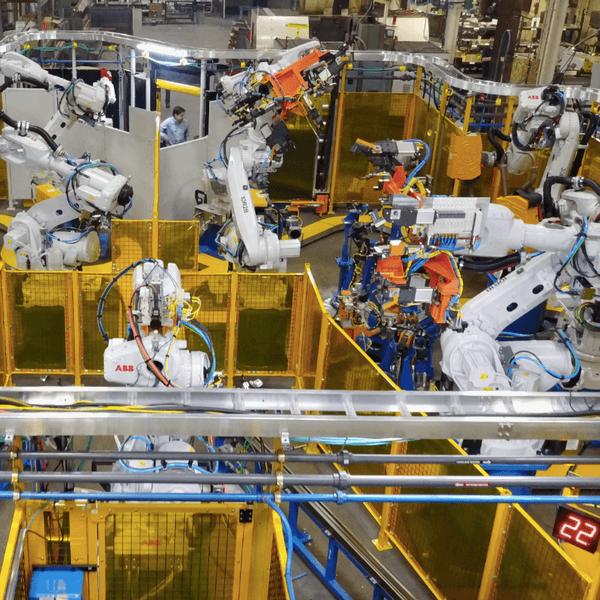

Mechanical Design

Johnathan

Major: Mechanical Engineering

This co-op semester I worked as a mechanical engineer at JR Automation Technologies. The majority of my tasks were related to one project. The project involved designing an automated machine to assemble industrial A/C compressors. When I joined the project the design was nearly 100% complete. Most of the engineers that were working on the project left to work on others. I became responsible for supporting the build team and dealing with any issues that came up during the build process. I designed some of the guarding around the machine and added sensors where needed. I redesigned some machine components when issues came up on the build floor with components that were not working as planned. I met with the customer to discuss changes they wanted to make to the machine that were not brought up in the original design meetings and processed an Engineering Change Order for their requests. Other mechanical engineers, controls engineers and machine builders taught me a lot this semester, I have gained tons of practical experience during my time at JR Automation.

Griffins Corporate Sales Intern

Mitchell

Major: Sport Management

My day to day tasks were split into two different categories based on what I was in the office for. For my "office hours" I was tasked with different data entries for donations and promotional inquiries. I was also in charge of the Griffins Kids Club where we organized memberships and created packages for the kids that signed up. Other "office hours" activities included preparing the promotional giveaways that happened for each game. For the days that we had games, we would often show up several hours before puck drop to set of the arena. This meant hanging banners, signs, rolling shirts, preparing coupons, setting up promotional tables, allocating promotional material to different areas and departments. During the game we would be tasked with different game time events and activities such as t-shirt toss, the smoke show before the game, Zamboni riders and much more. This was a fast paced and incredibly fun environment! I was also given the opportunity to put on the Griff Costume and make various different appearances for different videos and events.

Final Co-op Rotation

Bruce

Major: Mechanical Engineering

The two project that I worked on most were improvements to an existing product as well as the launch of a new product. I was around for the entire design phase for the new product.

'Controlling' the HVAC Industry - One Building at a Time

Anthony

Major: Mechanical Engineering

My co-op rotations were spent working with the contracting department. This department is contracted to building owners to install Building Automation controls. Once our sales department wins a job, the contracting department takes over the project management, engineering, installation, and programming of the controls. Specifically, I was/am involved in the engineering of this process. The engineering consists of creating Control Drawings for the installation and programming phases of the jobs. The Control Drawings show our electrical subcontractors and control technicians what controllers are going to be used throughout the job and what end devices / equipment are going to be used in the Building Automation System.

Read More About 'Controlling' the HVAC Industry - One Building at a Time

Ravenna Ductile Iron Co-op III

Spencer

Major: Mechanical Engineering

This semester, I worked with RDI's engineering team completing a large variety of tasks. These tasks included: cleaning and inspecting casting tooling, designing casting tooling, evaluating performance of said tooling, and determining appropriate solutions to any problems found. A major project completed was a redesign of several high volume tools to improve yield and decrease costs.

Internship in Athletics

Emma

Major: Sport Management

As Frostburg State University transitions from NCAA Division III to NCAA Division II, I am heavily involved in the application process. Some areas of responsibility include: assembling necessary documents to comply with NCAA application standards and recording the transition process by documenting meeting minutes and timeline. I also provided support at all home football games as the Department implemented new ticketing procedures.

Hutchinson NA Coop 1

Stephen

Major: Mechanical Engineering

Although this was my first official coop, I worked at Hutchinson NA last summer as an Intern. This gave me a huge advantage going into my coop semester because I had already completed all of my lab and safety training the year before. I was able to jump right in, working closely with engineers for projects for well known companies including Ford and GM. My primary role was designing fixtures for cementing, the process for preparing components to have rubber adhere to them, assembly, and testing of parts. I used SOLIDWORKS to design all of these fixtures.

Volunteer

Marie

Major: Political Science

While at the LAC, I assisted patrons with signing in and filling out a service agreement form stating they understood what we could and could not do for them. Once that was done, I'd ask, "how can I help you?", a powerful question that implies I am here to help you get through this, however I will not do all of the work for you. The patron will explain their issue and then I will explain what their options are. I can then set up the patron with the appropriate paperwork, help them fill it out and check it for completeness, set them up with a hearing before a judge (should the situation warrant it), and then instruct them on how to file the paperwork.

My summer with the Sierra Club

Rebecca

Major: Political Science

I worked on projects such as planning town halls and canvassing events, including connecting various venues. I assisted in creating GOTV campaigns for multiple precincts.

Recycling Engineering

Alex

Major: Product Design and Manufacturing Engineering

OSHA compliant guarding- from machinery to handrails for raised platforms. Platform designs for machinery, large scale material storage and transportation solutions- such as custom scrap bins and semi truck trailers. Multiple small scale projects to improve workflow and upgrade machinery.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.