Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Machine Design Co-op 1

Bryanna

Major: Mechanical Engineering

For this rotation, I handled smaller work orders coming from the manufacturing engineers at different facilities to the Machine Tool Services team that I was working on. These work orders involved using CAD programs to design small assemblies or adding to larger ones to solve issues that we were seeing on the assembly lines. I also took on all 3D print orders, many of which were used as prototypes to test designs. I took on a few longer term projects both of which involved in the automation of an entire assembly line for one of our most popular products. I was tasked with two projects within the automation project that will be used in the automated assembly line. Also at Herman Miller, as a summer intern, you are placed in a group of about 9 other interns, all from different fields of study, and tasked with a large project sponsored by someone higher up in the company. My group was given a sales and operational planning project, of which I knew very little of the topic. We met 1-2 times a week meeting with each other or with operational managers from all of our manufacturing sites in West Michigan. The project was meant to find the capacity constraints of each product lines, what would be required to do to add about 30% capacity to each of the lines, and to find issues within the supply chain. At the end of the summer, we were to present our information to our sponsors and whoever else joined us.

Summer Co-op

Josephine

Major: Mechanical Engineering

I worked as an ME and I drew up parts for machines. Everything was done in Solidworks. Sometimes I was working on modifications for existing machines, other times I was working on new machines. The last part of my time I was an unassigned resource and was able to work with a lot of different people and departments.

Mechanical Engineering Co-op

Austin

Major: Mechanical Engineering

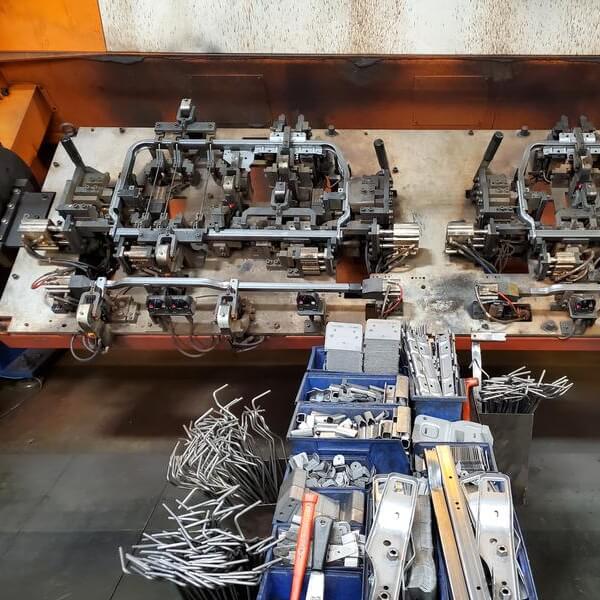

During my co-op, I worked on a range of projects dealing with robotic welding cells used for the assembly of auto seat frames. My work was mainly focused on the fixtures that the seat assemblies are welded in, modifying components or creating new ones using SolidWorks to help save money, meet new customer requirements, or increase quality of life for operators.

Mechanical Engineering Co-Op -- 1st Rotation

Chad

Major: Mechanical Engineering

This summer I completed a number of design projects related to continuous improvement in existing production flow. My role was design heavy, which entailed primarily CAD design. It also involved meaningful interaction with engineers, hourly team members, and production support to arrive at appropriate solutions to existing production issues. In some instances, I was involved in machining my designs from scratch.

Read More About Mechanical Engineering Co-Op -- 1st Rotation

Living Logistics

Beau

Major: Mechanical Engineering

I was a systems engineer at TGW. Our primary task was to take everything that was visualized in the sales phase and bring those layouts to reality. Gathering quotes and going on site to measure and map building columns and floor flatness along with meeting with the customer to approve drawings was a large part of the responsibility. Making sure that the system that sales built was going to be able to meet rate and also fit in the building was a tough task because in the logistics industry rate is everything.

First Co-Op Rotation at Nissan

Jordyn

Major: Mechanical Engineering

I had three main objectives for the summer and had a few side projects. My first objective was to categorize warranty claims for primary failed parts (PFP) on specific models manufactured at different plants; my second objective was to analyze shape data and key feature diagrams to determine if there were any discrepancies in the PFPs between each plant and determine any solutions to reduce warranty claims on these PFPs. My third objective was not related to the first two, it was to benchmark universal garage door openers (UGDO), specifically Homelink, among different OEMs to improve and amend our own Homelink quick reference guide (QRG) and owner's manual (OM) to improve our JD Power customer survey scores. Some side tasks include attending 20 hours of Nissan training, giving an intern introduction presentation, plant visits, and intern activities.

First Co-op Rotation with Innotec

Ryan

Major: Mechanical Engineering

The majority of my projects were geared toward machine improvement. This involved designing and assembling/installing components that solved an existing problem, or improved upon an original design. Some noteworthy projects include redesigning a part crowder assembly and designing an attachment that trims off excess material from parts.

In addition, I was also involved in a group intern project that helped to organize the material flow and layout of a new line.

First Rotation, Engineering Co-Op

Nathan

Major: Mechanical Engineering

Over the course of this co-op rotation, I helped to facilitate the required maintenance and repair of a wide variety of industrial automotive manufacturing equipment.

EGR 290 - Co-Op I

Brianna

Major: Mechanical Engineering

During my first Co-Op rotation, I was involved in designing prototypes, 3D printing prototypes, drafting and executing design verification and validation protocols, updating existing drawings, discussing action items for projects with customers, and drafting incoming inspection documents. For the first half of the rotation, I spent most of my time designing a connector that will be used in a new catheter design. For the second half of the rotation, I spent a lot of my time 3D printing the prototypes for this connector as well as executing the testing protocols for it.

Engineering Co-op at Flexco

Trevor

Major: Mechanical Engineering

I did engineering work involving testing, designing, building, and analyzing data. A lot of the projects took grit and determination, because they were massive and had different obstacles to tackle the whole way through. I like a challenge since it does my heart good to see it all finished and to feel accomplished at what I had achieved.

Great learning experience

Malcolm

Major: Mechanical Engineering

One of my main tasks was managing the 3D printing schedule and the prints themselves. I spent a good amount of time in the machine shop, doing development work in the lab, and creating/updating documentation.

1st Co-op Rotation

Bryce

Major: Mechanical Engineering

Pressroom:

-Worked production on press

-Helped change out dies

-Cleaned up presses

Die Shop:

-Worked production on press

-Learned about press simulating software

-Assisted in setting up parts for CNC

-Assisted in setting up parts for EDM

-Machined some punches

-Assisted in assembling die

Maintenance:

-Observed maintenance work on multiple machines

-Observed how weld adjustments are done

-Performed preventative maintenance

-Did maintenance on a pin press

Materials:

-Cycled Inventory

-Scrapped Obsolete inventory

Quality:

-Assisted with PPAP's

-Worked on pin hole diameter study

-Worked on torque testing study

-Worked on CAD tutorial in free time

-Designed gauge fixtures using Creo 4.0

-Worked on visual aids

Manufacturing Engineering:

-Worked on rework data analyzing tool

-Began rework data study

-Assisted with weld adjustments and fixture inspections

-Designed sensor bracket

-Assisted with headrest start up line

Estimating:

- Continued rework data study

- Worked on time study for assembling tasks

- Shadowed people to learn more about the estimating world

Continuous Improvement:

N/A

Assembly:

N/A

Engineering Co op First Rotation

Daniel

Major: Mechanical Engineering

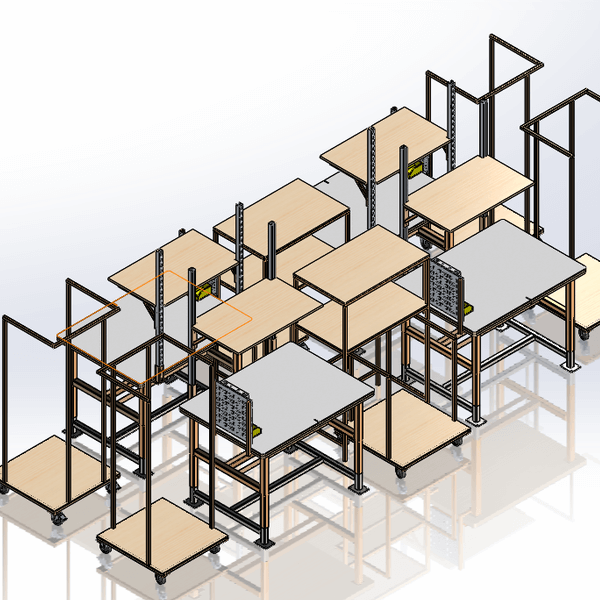

My main focus was to look for ways to improve efficiency in the Eames Lounge Chair cell. This involved creating new work stations for cushion upholstery and carts to transport foam in and out of the cell. This resulted in creating more space within the cell and better material flow.

Engineering Co-op Rotation I

Jenna

Major: Mechanical Engineering

Some of the projects I completed involved helping to control our processes. I used applications like MiniTab to take a statistical approach to each of our processes to better target nominal on dimensions called out in the blueprint. Other projects included designing a small visual gauge and designing a template to improve our welding process. Other tasks included assisting the quality and manufacturing engineer in trouble shooting daily shop floor issues.

Engineering Co-Op I

David

Major: Mechanical Engineering

Here at SAF-Holland, I have mostly been working on improvements to lab supplies and cost reducing tooling with regards to coupler products (Fifth Wheels). As the semester progressed, I got into more complex projects such as: redesign proposal for fifth wheel components, design of new crimping tool, FEA analysis on fifth wheel components, and much more.

Advanced Manufacturing Engineer

Eric

Major: Mechanical Engineering

Day to day activities includes quoting, part setup, tooling design, material deficiency report review and change order processing. On top of that, I also managed and co-designed three projects. The projects included a lathe, a automatic stripper and a sleeve machine.

M.E. Co-Op Experience with Team HS Die and Engineering Inc.

Steven

Major: Mechanical Engineering

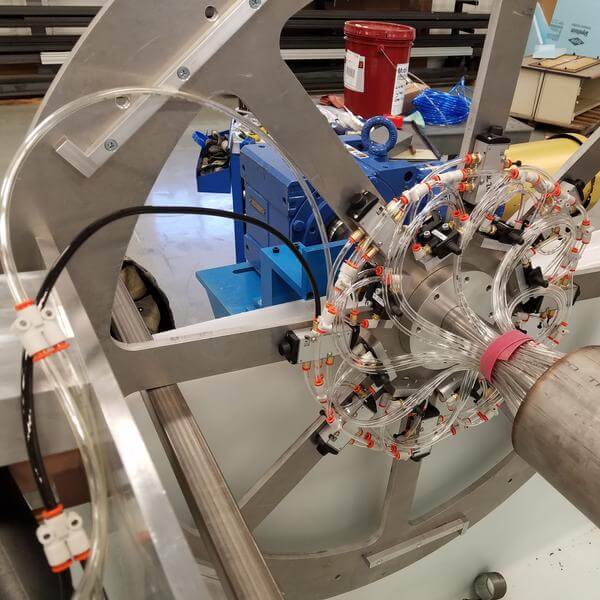

During this second Co-Op rotation, similar to previous rotations, I spent the majority of my time working as a mechanical engineering designer. I was responsible for designing automated machines and their respective components. The first half of the rotation I spent most of my hours designing components to solve the current problems we were experiencing while designing, building, and/or testing our automated machines. A problem would arise during the machine's designing, building, and/or testing phases so I would be assigned to fix the problem. While performing these tasks I was able to gain trust and responsibility from my supervisor and co-workers. Later in the semester, I was given my very own machine to design. I was able to go through the whole machine design process. I collaborated directly with the customer while designing the machine. I also continued to perform problem solving side projects while designing my own machine. In summary, I performed and learned a lot within the mechanical engineering design field. I spent 500+ hours using SolidWorks 2018 as well as 20+ hours of hands on building.

Read More About M.E. Co-Op Experience with Team HS Die and Engineering Inc.

Koops Mechanical Engineering Co-op

Jacob

Major: Mechanical Engineering

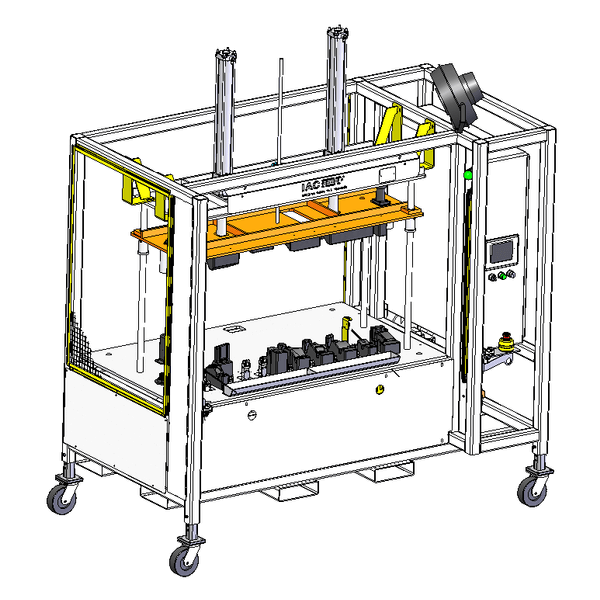

During my co-op rotation as a member of the Koops mechanical engineering team my primary responsibility was to work on the mechanical design of custom automation equipment. The main tasks associated with this were the creation of accurate and detailed CAD models, part drawings, and bills of materials (BOMs). During the winter semester I had the opportunity to work on numerous projects in both assisting and primary designer roles.

Co-op Rotation 2

Kyle

Major: Mechanical Engineering

One of the main tasks I completed during this co-op rotation was creating and managing graphics for completed projects. Graphics include floor plans, water systems, and air handlers. It was my job to ensure graphics were ready for technicians when it was time for them to program the graphic and get it ready for the customer to use. Another task I performed was creating record drawings. This entailed going into the drawings created by one of the project engineers and making changes. The changes made were a result of a technician realizing that something isn't portrayed accurately in the drawings while in the field. They would then mark up the drawings and give them to me to update.

Production Support Engineer

Aidan

Major: Mechanical Engineering

This rotation focused on manufacturing and was more closely tied to production. A lot of time was spent on the floor, building confidence in working with the team, scrapping out bad parts, and responding to alarms. After that knowledge base was built, Some Continuous Improvement projects began, such as dashboard setup, and line rework/modifications.

EGR 390 Co-op 2

Jacob

Major: Mechanical Engineering

Throughout the co-op semester, I worked on several K-12 education projects that involved designing new mechanical systems (HVAC, mechanical equipment, and domestic plumbing). I was presented with a higher sense of responsibility from my previous co-op by being given the task of fully designing a new HVAC system for an elementary school with the guidance of a full-time engineer.

Hutchinson Co-op 3

Alex

Major: Mechanical Engineering

At Hutchinson I was able to be involved in a variety of different tasks and projects in different labs and project groups. With the product development group I worked with I was able to test a variety of transmission and engine mounts for different performance and damping characteristics. I helped manufacture and modify prototype parts to tune performance. I also helped design test fixtures for parts for static and torsional testing. I experimented with design modifications to a part component using FEA analysis to look to decrease component mass. I assisted in developing bracket designs to meet stress targets and tooling clearance requirements. I helped conduct production process rate studies as well. Along with this I helped assemble and build a prototype heating unit for rubber to metal bonding and conducted heat studies. I also developed procedures for testing metal insert material compression yield strength.

EBWE First Rotation

Jacob

Major: Mechanical Engineering

I was able to design components being used on the floor today, quote them, and have them built to spec. I was also able to perform finite element analysis and strain gage testing as well. I created many CAD drawings for my fellow workers and wrote many engineering reports to follow up on my engineering experiments involving torque and load tests.

Second Rotation Mechanical Engineering Co-op

James

Major: Mechanical Engineering

During my second co-op rotation as a mechanical engineering student I was assigned as an intern to the Ford product development team working to meet production launch schedules. Studies where modifications to parts were made to account for variances in production parts and determine design solutions were frequently performed as tasks under a team project manager and project lead's guidance. I frequently visited suppliers of manufacturing equipment and assisted the industrialization team with troubleshooting early development level stations while running parts for shipment schedules. In my down time between tasks there was plenty to keep busy by helping with on-going projects and testing in the Validation lab. Troubleshooting of hydraulic pumps under the lab supervisor's guidance provided an interesting and unique opportunity.

Read More About Second Rotation Mechanical Engineering Co-op

Out there in the real world of engineer

Abdulelah

Major: Mechanical Engineering

I did a lot of different design tasks over the winter 19. creating an A-Frame for shipping purposes, creating a Solidworks lineup for couple cases next to each other. evolving the butcher block toppers to have the right dimension.

creating the end bumper to secured the cases. adding a tube of black silicone to a couple of cases. re-engineered couple of the drawing to have the machines making them.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.