Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

EBW Electronics Co-op III

Bryan

Major: Electrical Engineering

I did the PCB layout for a new product and put together all of the necessary design documentation. I also worked on creating thermal models of PCBs, so that the circuits hot spots can be predicted before prototypes are made. A couple other projects that I spent time on were working with an in-circuit programmer and helping with EMC testing.

MotorGuide Electrical Engineering Co-op

John

Major: Electrical Engineering

I validated product changes throughout the semester. From component level analysis to software changes, I made sure the final assembly worked properly as optimizations were made.

Hard Work Pays

Josiah

Major: Electrical Engineering

Sadly the project that I worked on this semester is confidential. I can only say that during this semester I worked with AC Phase control using microcontrollers, wiring harnesses and signal control. This project was one of the most difficult that I have ever worked on and I was lucky to learn so much!

third co-op rotation at Dornerworks

Aaron

Major: Electrical Engineering

I tuned a PID control loop for an embedded system. I documented the progress that I made. I changed a Python GUI for a customer.

Electrical Engineering - Hardware

Joshua

Major: Electrical Engineering

My job was to aide in designing circuits to be used for production or to support production.

Summer Co-op 1

Adam

Major: Electrical Engineering

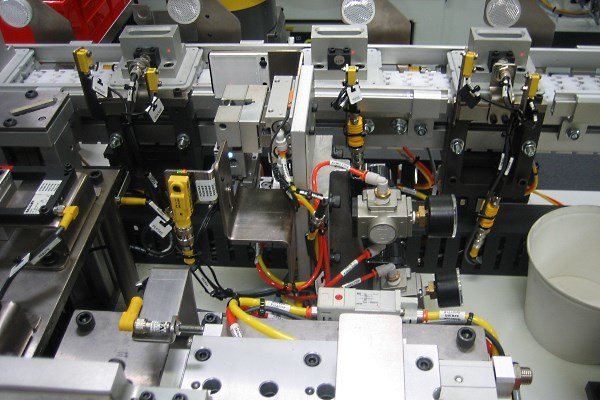

Over the semester, I was given multiple tasks. One job I was tasked with was setting up a camera attempting to detect a bead of silicone. On the same job I was also tasked with designing seven different HMI (Human Machine Interface) screens. This task of setting up the HMI screens introduced me to PLC, as well as several pneumatic and electrical drawings.

Trane - EGR 290

Mike

Major: Electrical Engineering

I created custom graphics for the user's interfaces. The graphics are used by the customers to monitor their HVAC systems. I was also responsible for checking in the parts that had been ordered for different projects.

Consumers Energy Low Voltage Distribution Co-op

Tyler

Major: Electrical Engineering

Projects assigned to me ranged from electric distribution line planning, concepts and designs.

Tasks required for these projects included many detailed drawings, creative designs, technical calculations and accurate cost estimates. Other tasks required customer communication, and coordination with electric construction operations.

In addition, I had the opportunity to tour many different Consumers Energy facilites that introduced me to other company operations such as the Webber Dam Hydro Plant, Ludington Pumped Storage, and J.H. Campbell Coal Plant.

Read More About Consumers Energy Low Voltage Distribution Co-op

Experience at TwistHDM

Kyle

Major: Electrical Engineering

Validation for a new generation of our controls circuit involved a large amount of electronics testing equipment under temperature extremes, voltage surges, and many other "what-if" situations to ensure the product is bullet-proof. This also included fine-tuning of component values and the code accompanying it, applying external modifications, and actively looking for issues and addressing them as we go.

RF signal analysis using spin-testing in various configurations.

Root-cause analysis of components that failed in the field and working with manufacturing to address the problems.

Analysis of sensor effectiveness in various climates using Python scripts to interface with data sent from our controllers.

Supporting the engineers: applied many intricate mods to boards which involved cutting & re-routing PCB traces and replacing small surface-mount components.

Dornerworks First Rotation Co-op

Kevin

Major: Electrical Engineering

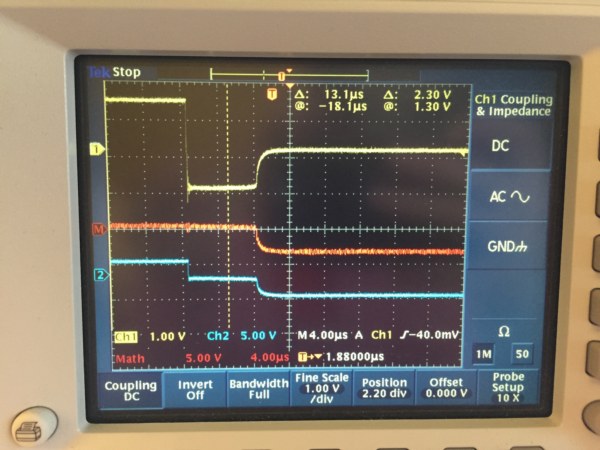

I was taken in as a hardware engineer co-op and thus all my tasks were hardware focused. I was task with making most of the board modifications for the lead engineers on the project team. I was also put in charge of functionality and performance testing of the many different circuits located on the customers PCB. This involved obtaining and setting up software to control specific signals and verify that the circuit functions as expected on both an analog and digital level. Also, I had to introduce the boards to worst case scenario options and verify that the designs did not fail. If the designs did fail it was my responsibility to help diagnose the failure and verify the the correct changes were made in consultation with the lead engineer. I spent most of my time in the lab working with oscilloscopes, DMM, and other electronic tools during the verification. I was also put in charge of the mechanical testing of the design in which the PCB boards would be enclosed in. This project involved exposure with the external customer and other engineering companies.

Summer Co-op

Chris

Major: Electrical Engineering

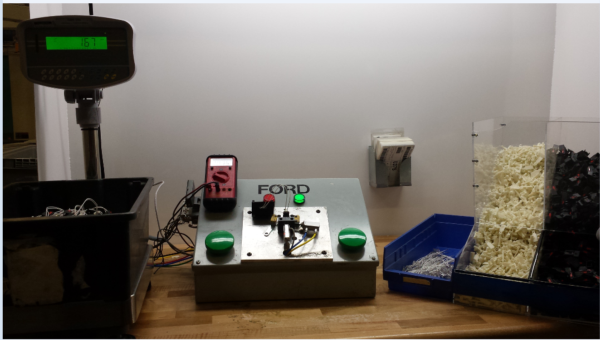

I worked with the office group to help design prototypes, repair and maintain part testers for the production floor, worked with Altium to design schematics and board layouts. I also made testers for ITW so they could test some of the boards we sent them. Along with working with the office group I also helped out the production floor with creating test fixtures and programming and testing parts.

Electrical Engineering Co-op 1

Nicholas

Major: Electrical Engineering

Most of the tasks and projects that were completed included C programming, hardware testing, and the interaction between software and hardware. Test engineering is important for keeping manufacturing error to a minimum.

Working as a contractor

Josiah

Major: Electrical Engineering

This semester was split into two halves. The first half had me working at Disher on small customer or stewardship projects. I also spent time during this semester learning the coding language of Python. The second half of the semester I spent working as a contractor for one of Disher's clients as a components engineer. I helped the client's components engineer transition the company to a new database software and check their old database for errors.

Largest and Great Company LG

Yoonsun

Major: Electrical Engineering

About work experiences, LG Chemicals are dealing with lots of automation devices. I learned process of battery production. Electrically, I was also dealing with lots of automation program. I was not actually designed a program. However, I had experiences with finding a problem on PLC Program.

Because I can speak Korean, I also worked with Korean technician. And then, I educated other engineers, operators and American technician.

Twisthink Co-op Round 2

Audrey

Major: Electrical Engineering

This round of co-op I was able to expand upon my programming skills by learning C#, and created several WPF applications during the planning and exploration phase of a project TT was working on. I studied the feasibility of various concepts such as drag and drop, reading/writing XML documents, and custom styles in WPF by creating these demo apps.

In addition, I did a fair amount of hardware validation testing. This included taking measurements such as ripple voltage with different applied loads or transient response, and then making modifications to improve the performance. Similarly, I wrote some software unit tests to verify another board's performance for a separate project, as well as taking physical measurements and constructing graphs to display the data.

I also did some research on live streaming, and extracted information about the various protocols, streaming providers, and how products that exist in the market accomplish streaming.

Engineering Co-op at Magna Mirrors

Jay

Major: Electrical Engineering

I received a wide variety of task throughout the semester. I spent a lot of my time making mockup mirrors. This required me taking mirrors apart, making some form of modification to an area of interest inside the mirror, building the mirrors back up, and then testing the new mirrors for desired performances. In doing this I spent a lot of time in our shop, gaining familiarity using some of our machining equipment. I also was exposed to a number of different testing procedures including current draw, vibration, water spray, wind tunnel, and several others. In addition to these tasks, I was able to gain some electrical engineering experiences as well. I performed circuit analysis on a few turn signal modules, populated and modified a few sets of PCBs, soldered together multiple wire harnesses, and was even able to run some EMC testing.

EBW Electronics Co-op II

Bryan

Major: Electrical Engineering

Throughout the semester I did some electronics hardware development as well as a write some firmware for a microcontroller. Some projects included use of electronics lab equipment. I also attended meetings with customers and suppliers, as well as learn more about other areas such as manufacturing processes.

Co-op II: Innotec Group

Lauren

Major: Electrical Engineering

In terms of electrical projects, I completed a limit switch project, thermolator project, planned a large controls project, and learned about extensive relay logic. With these projects I learned new 2D CAD software, how to properly draw my own electrical wiring diagrams from scratch, how to work with relays, how to use auxiliary contacts, and much more. I also worked on putting together on-line electrical-check stations for some of the products that my team produces, fixed countless wire and connector damage, updated sensors, and x-rayed parts to help understand electrical failures.

Mechanically, I learned how to operate a manual three-axis mill,successfully milling limit switch stops, an entirely new electronic-check station for one of our products with over ten detailed parts needed, and color check stations.

Additionally, this semester I assisted our launch team. I made over a dozen unique prototypes for a new product on a CNC machine, which required learning a new CAM software and a new milling interface. I measured light intensity and color data for thousands of parts for multiple new products. I also helped perform analysis on diode functions and analyzed multiple different design performances to choose which scheme should be kept for a final product launch.

There were so many more amazing experiences that I worked on, from presenting at company meetings, attending design reviews, ordering materials [working with supply chain], to assisting with 5S projects. I learned something new every single day at work, and I highly recommend Innotec to anyone who wants a fast-paced, hands-on job!

GE Aviation Electrical Engineering-Dayton

Aaron

Major: Electrical Engineering

Some C-programming, little circuit design, lots of hardware debugging and rework (soldering).

Controls Engineering Co-op

Marshall

Major: Electrical Engineering

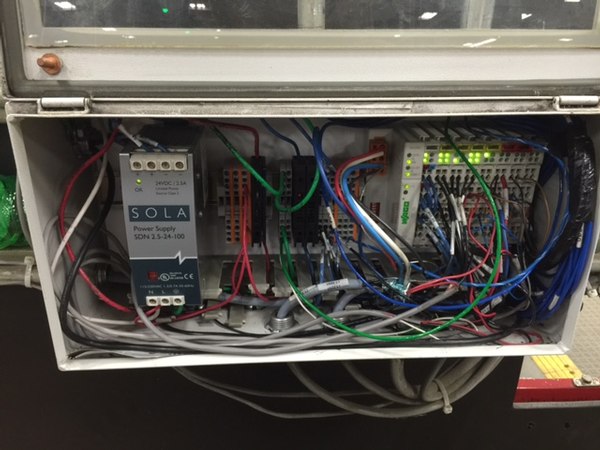

Over the course of the semester, I worked in a manufacturing facility operating controls equipment such as PLC's, safety equipment, and network communications equipment. I used ladder logic to solve issues with machines' programming, AutoCad Electrical to generate electrical wiring diagrams and panel layout prints, and physical components to modify and update machinery.

Co-Op at Magna

Alexander

Major: Electrical Engineering

This semester I participated in a variety of EMC, Spot meter, Illuminance Reduction, Current Draw, Extreme Environmental Resistance, and Light Consistency Tests.

I also assisted with various design alterations and testing concerning a prototype rearview camera design and several prototype light indicator module designs.

Electrical Engineering in the Architecture/Engineering Industry

Greg

Major: Electrical Engineering

I aided in the layout and design of lighting systems in new construction buildings as well as historical renovations. I also provided design assistance in the layout of power distribution systems within these buildings according to local, state and national electric codes. I provided assistance on a variety of different building projects for K-12 education, higher education (including projects for Grand Valley State University), historical building renovations, healthcare facilities, and large scale airport renovations.

Read More About Electrical Engineering in the Architecture/Engineering Industry

Test Software Engineer Intern

John

Major: Electrical Engineering

During the time spent here, I was able to be involved in many different areas. Anywhere from fixing problems that arouse in the production line (both hardware and software), to developing software and hardware used to test new units going through qualification testing. The task that I was able to spend the most time on was writing/updating code for stations that were being upgraded from Windows XP machines to Windows 7. Much of the hardware used in Windows XP is not supported in Windows 7, therefore the code had to be altered to communicate with a new pieces of hardware. This gave me the opportunity to learn how many different communication protocols work, and how to interface with many different components.

Co-op at JR Automation

Kevin

Major: Electrical Engineering

Projects and tasks included writing a PLC program to control and monitor equipment (heat gun) via interfacing Allen Bradley ControlLogix systems with hardware by generated tags (timer and control). Also, it included creating a Macro to assist in importing and generating data for use in software. It also included human machine interface design and implementation on machines to interface between machine and operator and also included data transfer via machine to databases.

Co-op I: Innotec Group

Lauren

Major: Electrical Engineering

I helped wire machines, build machines, create and update schematics, use CAD to design solutions, and helped move a launch product into production. I also was able to learn how to use different electrical equipment and conduct studies directly for our customer.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.