Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Fall 20224 Co-op at EBW Electronics

Logan

Major: Product Design and Manufacturing Engineering

I collaborated closely with manufacturing engineers and technicians to enhance the ergonomics, optimize cycle times, and increase throughput across some of the highest-volume work centers in the facility. Additionally, I supported the ramp-up of new products to full production capacity, ensuring a smooth transition from the safe launch phase to active manufacturing.

Manufacturing Engineering Co-op

Kyle

Major: Product Design and Manufacturing Engineering

I provided support to the production floor by addressing real-time issues and minimizing operational disruptions. I analyzed machine capacity to optimize production targets. I developed a performance tracking system using Excel and Python to monitor key metrics like downtime and output, which helps engineers identify what issues are most important to address. I created detailed process instructions to standardize operations, reduce errors, and empower team members to solve problems independently.

MAGNA Mirrors CO-OP 1

Jonathon

Major: Product Design and Manufacturing Engineering

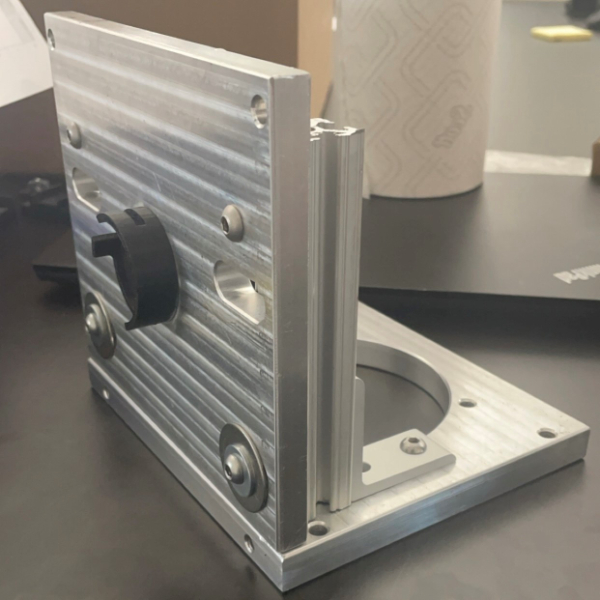

In my time working at MAGNA Mirrors, I was able to do a few gauge R&Rýs to test new and old measurement techniques and tools for repeatable and reliable measurements. Iýve also helped with building and testing mirrors at different MAGNA locations, and I designed and constructed a few fixtures that would for modifying mirrors, such as the one in the provided picture. I was also taken along and sent to different locations for our customers and dealerships to help diagnose problems and replace mirrors.

Autocam Medical First Engineering Co-op Summer 2024

Antonio

Major: Product Design and Manufacturing Engineering

Part of the training Autocam gives every engineering co-op student during our first rotation is a hands-on learning experience on the floor to enhance our understanding of their manufacturing process. In my case this involved learning to operate lathe machines for turning operations. This implicated not only learning about the machines themselves (debugging, set up, tool change, offset adjustments, etc.) but the results of the quality of each part that is made and how small details carry throughout the entire job (most comprised of hundreds of parts).

Read More About Autocam Medical First Engineering Co-op Summer 2024

First Co-Op Rotation with Genesis Seating

Casey

Major: Product Design and Manufacturing Engineering

In my role as a manufacturing co-op engineer, I spend a lot of time working on process improvement. I am often out on the plant floor talking with employees about how I can improve their jobs, which can be anywhere from increasing production volume to reducing discomfort due to manual labor. Basically, I design and implement solutions to make our situation better.

Viking Products Engineering Co-Op

Logan

Major: Product Design and Manufacturing Engineering

As an engineering Co-Op, I had the opportunity to work with all the engineers at Viking on various different projects. My responsibilities spanned the entire production process. One day I would be creating prints for new parts, and reaching out to our suppliers, and the next I would be testing the parts before they went out to our customers. Additionally, I provided support in Viking's assembly areas getting to set up and test the latest equipment and processes.

Great Coworkers Make All the Difference

Corey

Major: Product Design and Manufacturing Engineering

As with the first two rotations, we are expected to conduct EMC tests; This time around, however, we were challenged to operate with more independence. I was assigned tests I had never conducted before and was trusted to be able to either figure out how to do it and know when to ask for assistance. We were also tasked with communicating more frequently and directly with clients, just like the full-time engineers.

Herman Miller CoOp Fall 2022

Dylan

Major: Product Design and Manufacturing Engineering

I worked as the primary operations engineering support for the machining area in Casegoods manufacturing. I also helped integrate 3D printing into the plant and trained some of the engineers at the plant on 3D printing common practices and modeling.

SoundOff Signal Co-Op

Kristen

Major: Product Design and Manufacturing Engineering

The internal projects I completed included, but were not limited to, designing a part in CAD for our goniometer to fix the chain slack, designing an LED sign for Project Night Lights, and creating an updatable bracket wall with all of our sellable vehicle specific accessories. I was also tasked with designing multiple sellable bracket products.

Herman Miller Co-op

Jarrod

Major: Product Design and Manufacturing Engineering

I was tasked with day to day operations of running an assembly line. This included tasks from improving safety like creating new stapling processes to improving machinery to make lines more efficient. I was also tasked with larger products like helping with new product launches and creating floor layouts.

Koops Summer Co-op: First rotation

Cory

Major: Product Design and Manufacturing Engineering

During my summer semester, I was a part of the Controls Programming team. My mentor and I worked on an automated conveyor line used to assemble a small oil pump. From day to day we problem solve issues involved with programming, vision systems, robots, sensors, and lights.

Manufacturing Engineering Co-op at Herman Miller

Nick

Major: Product Design and Manufacturing Engineering

I worked on several projects that target creating manufacturing department more efficient. For one project I tested cycle times on a boring machine on our manufacturing line, and then presented results to the machine's manufacturer based in Italy.

Read More About Manufacturing Engineering Co-op at Herman Miller

GVSU PDM Engineering Co-op with Haworth

Emily

Major: Product Design and Manufacturing Engineering

One of my most favorite things about working for Haworth is the large range of projects, both in time span and complexity. There is always filler work to do whether it's updating CAD files, or costing products in the system, or progressing through the stages of changing a product that's already in production. Additionally, I have had the opportunity to work on projects that have lasted several months. A lot of these projects have pertained to looking into the future and analyzing trends in order to brainstorm and cost products that may be popular in a few years from now. These projects are always incredibly interesting because you have to interact with so many different people in order to get enough input and questions answered so that you can justify your decision making. Lastly, there are projects that fit in between the long term and short term time span, but are just as important. For example, sometimes customers receive orders that are incorrect and you have to diagnose the problem, fix it, and go through a lot of other steps under a specific time limit depending on the demand for that product. If you are looking for an internship with a broad range of projects, Haworth does an excellent job providing exactly that.

Engineering Co-op

Nicholas

Major: Product Design and Manufacturing Engineering

I worked as part of the engineering sustaining team. I worked with an engineer to maintain three manufacturing lines and assist in moving out one of those lines at the end of march. I wrote and worked on a wide variety of documentation for each line as well as performing hands-on maintenance for the lines.

Creating a Seat at the Table

Patrick

Major: Product Design and Manufacturing Engineering

I participated in many projects in my experience at Genesis Seating. Shelving units and manufacturing fixtures were created to improve ergonomics and efficiency within the cell of a main chair line of Herman Miller, as well as cell layouts, which were redesigned to increase efficiency. A proposal was created for the re-design of an assembly station for the Eames Plastic and Wire chair line from Herman Miller. Torque specifications were gathered for battery, pneumatic, and electric drills from each cell in the factory. Finally, I re-designed a leather buck to expand and contract to improve ergonomics for the leather cutters.

Third co-op rotation at Autocam Medical

Zachry

Major: Product Design and Manufacturing Engineering

For my third rotation I took on a full manufacturing engineer's role. I focused mainly on new product launches and production support for our bone screw division. I also completed many continuous improvement projects for secondary operations such as bead blasting and electropolishing.

3rd Co-op Rotation

Avery

Major: Product Design and Manufacturing Engineering

I was assigned tasks throughout the semester that required me to design new tooling to make parts and to modify old tooling to improve our stamping processes. I also worked on a task researching new 3D printing technology that we might want to implement at Trans-matic

Herman Miller Co-op 3

Chase

Major: Product Design and Manufacturing Engineering

This rotation, I was placed into more of a quality engineer role in an area of the company that packages the tabletops that we manufacture. My largest project this semester was to make an impact in the quality issues we had in fiscal year 20. In order to do this, I was placed on a blitz team that added multiple quality verification steps to the operator's jobs on the packaging line. Designing these checks in a way that makes them efficient was one of the early tasks of mine. Through data collection, it was concluded that almost 20% of our quality issues came from a singular supplied hardware box that we pair with our tables and ship to the customer. On top of the checks implemented on the line, I've been designing a process to "poka-yoke," or "error-proof" the way we package and ship these boxes.

ODL A Great Place To Work!

Caroline

Major: Product Design and Manufacturing Engineering

I worked on design feasibility and verification. I designed and performed experiments to identify and compare the robustness of potential design solutions. I also completed comparative analysisýs of design concepts. I learned how to document results to clearly compare the performance of multiple design concepts. And lastly, I dove deep into Design and Manufacturing Engineering documentation and gained technical skills. I had the opportunity to learn how to complete important design and manufacturing engineering documentation as well as understand the importance of each document.

Flexco - 2nd Co-Op Rotation - New Product Development Engineering

Trey

Major: Product Design and Manufacturing Engineering

During my second rotation at Flexco in the New product development department I mostly helped with the manufacturing of a new product. I was given other tasks that involved designing a new mounting system for a new product. I was given other miscellaneous tasks throughout the semester that involved a lot of SolidWorks and mechanical design.

Read More About Flexco - 2nd Co-Op Rotation - New Product Development Engineering

Magna Mirrors Engineering Co-op 3

Jacob

Major: Product Design and Manufacturing Engineering

This semester I worked along with product engineers in the door handle product development department. Throughout the semester I helped with the design and validation of various handle projects for numerous leading car manufacturers. Since the facility I worked at is an R&D facility, I spent a lot of time in the tool shop and validation lab modifying and testing handles for travel, effort, water ingress, and freeze testing. This semester I also started to work with designers to make changes to products I was working on. I was able to get FDM prototypes made and evaluate my designs. Along with testing, I was also tasked with filling out the DFMEA (Design failure mode and effect analysis) document for one of our new programs. This is a very important document for the beginning of a new program and it allowed me to learn a lot more about what is required and expected from engineers in industry.

Product Design at ODL

Callie

Major: Product Design and Manufacturing Engineering

I have had the opportunity to dive deep into hands on projects. From sketching, CAD, and Prototyping to seeing the product manufactured and shipped to customers it has been a really special opportunity. I worked directly under a mentor and was challenged and guided to learn the basics skills and behaviors that will lead me to be a great engineer. I spent my first co-op rotation in current product development and my second rotation in new product development.

Magna Mirrors Engineering Co-op 2

Jacob

Major: Product Design and Manufacturing Engineering

This semester I worked along side product engineers in the door handle product development department. Throughout the semester I helped with the validating and prototyping of various door handles for numerous car manufacturers. I spent a good majority of my time working on durability and ultimate strength testing for door handles. Along with that I did an in depth DOE on salt water submersion tests and its impact on the capacitors in electronics. I was also given my own design project/DOE for developing the next generation of switches that will be used in Magna's future door handles.

Great Co-op Experience

Robin

Major: Product Design and Manufacturing Engineering

" Designed assembly cells and fixtures for the Aeron, Cosm, Case Goods and Vivo lines

" Collaborated with line engineers to interpret initial problems and provide solutions within established time, budget and quality expectations

" Responsible for material selection, implementation footprint, scope of work, bill of materials and manufacturing processes for each solution

IPM Mechanical Engineering Rotation 3

Gavin

Major: Product Design and Manufacturing Engineering

As a Co-Op at IPM, you have the same job responsibilities as your engineering mentors. Because IPM is a systems integrator, we get to work with both other individualsý equipment, as well as develop our own custom machine centers. The major, high-level task for a given project, include developing a plant layout, designing custom equipment in 3D cad, releasing equipment, guiding the build and providing installation support. As a Co-Op student, you will likely get to touch each of these steps on large projects, as needed, or you may get to complete all of them on a smaller sided project, depending on the work that is needed to be done.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.