Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Herman Miller Green House

Stephen

Major: Mechanical Engineering

I was assigned a section of the factory for which I was responsible. As a manufacturing engineer, my job was to make the operators job faster and easier. I solved day to day problems as well as working on long term projects. A few projects I worked on were prototyping a design a vacuum lift assist device, designing a unique tool using modeling software, and managing departmental moves.

Engineering Co-op

Andrea

Major: Electrical Engineering

Testing and quality control of device firmware, including the writing and development of automated firmware tests.

Project Management at Koops

Sam

Major: Electrical Engineering

I was assigned to the project management team, and was able to work on a variety of tasks and projects. I was tasked with my own project to manage, a small cell containing a single robotic unit. This project provided an excellent introduction to project management. I also assisted in working on various other projects, including multiple robotic sonic welding and clip driving stations, and a resistance welding cell.

Electrical Controls Systems in Manufacturing

Nigel

Major: Electrical Engineering

I was responsible for keeping wiring diagram drawings up to date with the machines that were on the manufacturing floor. In addition, I did programming and debugging for multiple Allen Bradley PLCs and an HMI (Human-Machine Interface).

Read More About Electrical Controls Systems in Manufacturing

Web Developer

Collin

Major: Computer Engineering

The projects in the IT department that I dealt with starts simple with writing acceptance criteria, where I would have to write the specifications of the current page, the required data that the user must input, and the required functionality to be added for a page update. To mild difficulty where I would be fixing bugs that were on the current page to help prevent page errors and improve the user experience. As well as this I would help with user interface updates, where I would make sure the page is saving the information properly, displaying the appropriate fields at the appropriate time, making sure the layout of the page is up to the standard of the company. As well as making sure the page was properly functioning and alerting the user of any errors/missing fields that they may have had. My attached screenshot is just one of the many pages I helped with. To the hard projects, such as conversion of pages to Angular, where the page would be completely modernized and updated.

Co-op at Dominion Systems

Collin

Major: Computer Engineering

Tasks, assignments, and projects that were worked on at Dominion Systems varied from bug fixes, redesign of pages, and complete rework of pages on our web application.

Engineering Co-op

Kyle

Major: Mechanical Engineering

Throughout this summer i have done work on many gages for many different customers. Each gage is assigned to a specific experienced builder and i had the chance to help the builders complete gages by either machining parts for the gage or assembling the gage with them. I also had the opportunity of working in our CMM lab (Coordinate Measuring Machine) where i was able to measure the final stage of the gage to make sure that gage met our customers standards before we sent the final product to them.

Engineering Co-op

Gabriel

Major: Product Design and Manufacturing Engineering

I converted ACAD and Inventor drawings to SolidWorks models and drawings using advanced modeling techniques. This involved aiding the development of an updated drafting standard based on current ANSI standards. Additionally, I completed time study analysis and completed several Engineering Change Orders (ECO's) for components that were being converted. Lastly, I designed and produced piece parts for an antenna for one of our customers based on military specifications. This project involved working hands on with machinists to understand manufacturing processes and with senior Engineers for precise Geometric Dimensioning and Tolerancing (GD&T).

EGR 290: Co-Op Experience

Breanna

Major: Product Design and Manufacturing Engineering

With Surge Cardiovascular, projects and tasks that were completed include the implementation of an antimicrobial wound care product line, updates to product packaging design, performing and completing design validation and verifications for a variety of tests on multiple product families, update to general documents, and completion of performance qualifications to validate manufacturing equipment and processes.

JR Automation Controls Engineering Co-op

Robert

Major: Computer Engineering

The tasks I completed were largely dependent upon the project I was placed on, which I am not at liberty to disclose details about. In general terms, I did a great deal of HMI work, configuring and programming of numerous different devices around the line, teaching points to robots, device testing, and a whole lot of debugging. I also spent time communicating with suppliers regarding defective units for some of the devices and getting them replaced, updating electrical schematics in 2D CAD, as well as meeting with builders and electricians to determine solutions for some problems arising regarding alignment of mechanical components and wiring.

App State Campus Recreation Summer Internship

Isaac

Major: Sport Management

I worked with all six programs within the Campus Recreation. I did things with inventory, budgeting, planning outdoor trips, risk management mapping, closing the facilities, and more. I got a wide variety of things to learn within the office setting.

Read More About App State Campus Recreation Summer Internship

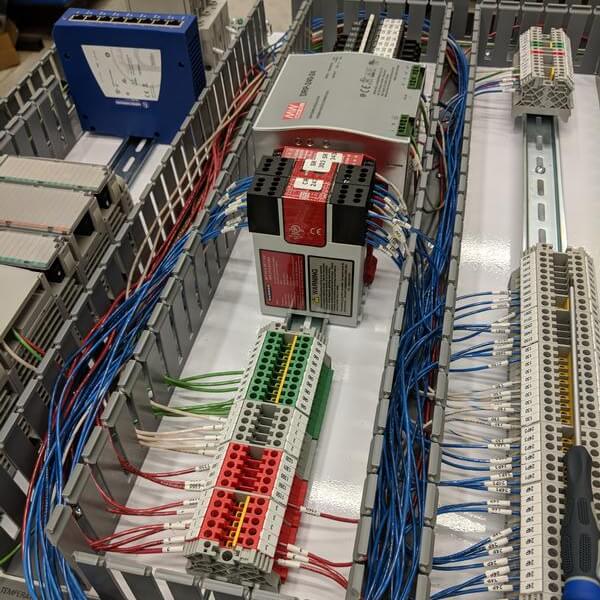

Controls Internship - 1st Rotation

Jaret

Major: Electrical Engineering

My tasks included building control panels, wiring machines, editing electrical schematics, debugging machines, and programming PLCs. I also did some work with a client who needed a secondary HMI display on a few of their machines.

A Summer at Phase One

Benjamin

Major: Electrical Engineering

Buying parts for PCBs.

Construction of several perfboards for demo circuits.

Taking radiation patterns from a PCB with helix antennas.

Making Helix antennas by wrapping copper wire around an high dielectric material.

One big project I did was swapping out a old modem that ran on Verizon's 2G/3G network to Verizon's 4G network. This included getting familiar with AT commands and Mobile network infrastructure.

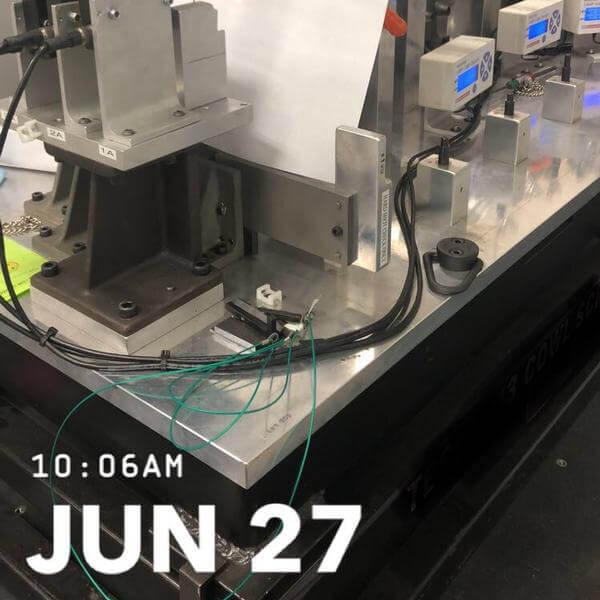

Hutchinson Engineering Co-op

James

Major: Mechanical Engineering

Tasks and projects given were extremely varied and well rounded for an entry level internship. Working through different departments such as the characterization and prototyping lab then being tasked to assist with manufacturing and pre-production approved cells to create parts was the majority of my co-op experience. There were intermittent projects given to perform jobs such as designing shielding for machines, modifying parts for tuning purposes, and preparing display pieces.

(Injection) Molding My Future

John

Major: Mechanical Engineering

I was directly involved in the testing and developing of a new part for production. This included testing prototypes- both dimensionally and for performance, performing durability tests, assembling parts, and working with my supervisors to recommend changes. My primary duty was carrying out all testing of parts, writing reports on my findings, and then working with my supervisor to identify design and process changes that were necessary. I also was involved in the production of most sample parts produced during my time there. I worked on multiple different molding machines for different components of the part, did coil winding, welding, and final assembly of components. I also completed several projects related to documenting both critical dimensions of new components in our database and creating instructions for quality inspections, testing, and production.

Co-op Rotation I

Kyle

Major: Mechanical Engineering

During my first rotation at Trane, I worked to create graphics for projects in which the engineering work was recently completed. These graphics include floor plan, air handler, and water system graphics. It was also my job to check in parts that were ordered by the engineers and ensure everything that was ordered had arrived.

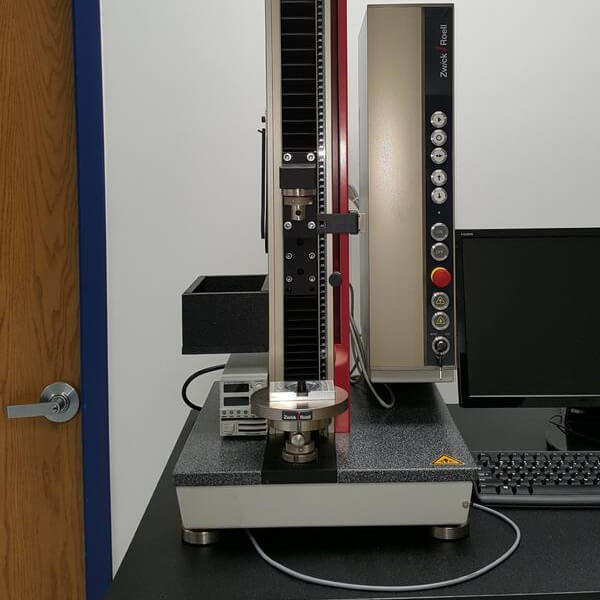

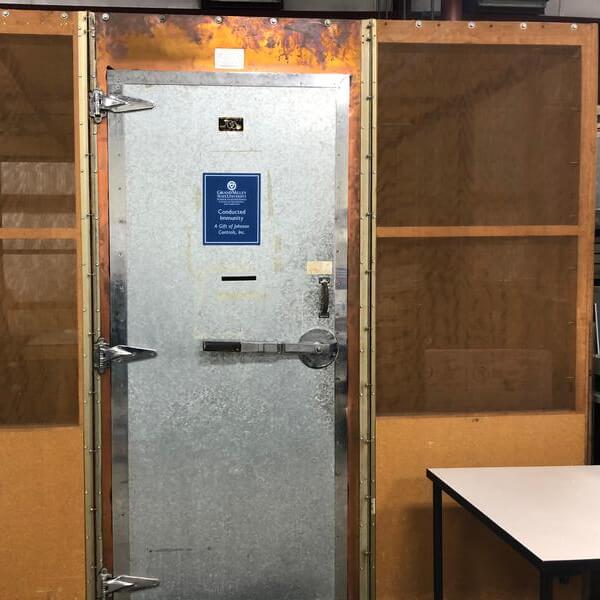

Working in the world of EMC

brittany

Major: Electrical Engineering

I did a variety of tasks, some were day to day tasks which include several types of testing such as radiated/conducted emissions and radiated/conducted immunity. These tests would include working with customers, modifying products, and assessing data. Other tasks completed were long term projects that benefited the efficiency of the lab such as generated lab reports and creating profiles for testing standards.

H.S. Die Engineering Co-op Student

Vincent

Major: Product Design and Manufacturing Engineering

My daily tasks consisted of: testing the glass content of polypropylene production products, documenting functional and safety improvements to the plant, and inspecting molded parts for quality. Projects completed include: the creation of a safety data sheet booklet for chemical hazard reference, development of standard operating procedures for plastic injection molding, and data extrapolation for mold scoring.

Ravenna Ductile Iron Co-Op I

Nicholas

Major: Product Design and Manufacturing Engineering

Throughout this semester I worked with RDI's engineering team, performing a variety of tasks to gain a broad understanding of the engineering aspects of a foundry. This included the cleaning and examination of casting mold patterns for damage or defects, scrap analysis of castings to determine patterns in defects, and CAD work to create new mold patterns or modify existing ones. A major project completed was the reverse engineering of a transferred pattern, utilizing measurement techniques and CAD skills acquired in earlier EGR courses.

Communications and Golf

Jack

Major: Communications

I assisted with open play, anything golf outing related, maintenance work, pro-shop work, social media and advertising for the course, and concession work.

Learning Experience

Elgin

Major: Communications

We must provide walk in tours for customers

We set up onsite outside to advertise to potential buyers

Make high priority calls

Provide incentives to convince consumers to buy.

Engineering Co-op, Koops Inc.

Joseph

Major: Mechanical Engineering

My co-op time in Koops was spent in the Business Development team and was split into two distinct sections: Sales and Applications.

In Sales I was introduced to the company, our structure, organization and products. I learned to be the front face of the business presenting customers with solutions for their manufacturing needs. Doing site visits, taking phone calls, and responding to website leads were part of my jobs. The most major project I undertook in Sales was an email campaign to revitalize old customer leads with whom we had lost contact. More than three hundred emails later and I am still responding to healthy sales leads.

Applications taught me how to quote a project. When a customer sends us a request for a quote it's the job of the applications team to put together a comprehensive, itemized list of parts, components and manpower necessary to complete it. Quoting involves a certain level of engineering creativity to discern the most efficient, feasible and economic solution to each problem.

Herman Miller 2018 Summer

Andrew

Major: Electrical Engineering

Throughout the summer, I've been introduced to a few different types of work at Herman Miller, Spring Lake location. Early on, I started with basic PLC programming using Rockwell software's RSLogix 500. There were a few simple assignments such as mimicking a stoplight sequence and taking the positions of analog sensors. As the summer progressed, my work team lead began assigning me work orders that consisted of issues throughout production. Many of these issues were caused in the PLC programming, whether it be timers that weren't correct, or certain limits that needed to be changed. The most exciting portion of updating the PLC programs is that everything was done online with the controller, so the machines and assembly lines were still running while the changes were being made. Most of the assembly lines and machines are programmed using RSLogix 5000, which is an expansion of RSLogix 500 and offers more functionality to a programmer. Later on in the summer I began working with the HMIs(Human Machine Interface) which are the main interaction between the line workers and the assembly lines. We try to design and program them as simple as possible, while making sure they have maximum functionality. Towards the end of the summer, I started working more with AutoCAD electrical for designing controller layouts and schematics containing sensors, switches, and other components. Along with the wiring schematics, I designed a few control panel enclosures that were later installed for a temporary project on a couple of the smaller assembly lines. The rest of the time this summer was spent working with my project team on the summer intern project. Every intern is placed into a group with 7 or 8 other interns and given a real company issue and the team is to present their solution at the end of the summer in front of the project sponsor, CEO, and many other employees.

Mechanical Engineering Co-Op Experience

Austin

Major: Mechanical Engineering

Tasks at HMC has a large range. Tasks include, SolidWork designs for new or improved tooling, data collecting and excel work, and hands on technical work. The main focus of my rotation was in the foundry. Creating new processes and improvements to increase productivity.

Committee to Elect Rachel Hood

Natalie

Major: Advertising & Public Relations

This role was very heavy in community relations. I had to engage the community and build relationships. I coordinated events and did a lot of volunteer recruitment. I also was in charge of social media and developing tactics such as posts, fliers, and event execution schedules.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.