Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-Op 2

Jacob

Major: Electrical Engineering

I worked in the Mechanical Engineering department. I spent my time creating parts, assemblies, and drawings in Solidworks. I often created or modified individual parts for existing machines, but on several occasions I designed groups of parts for larger changes. On some occasions I worked on internal development projects.

Controls Co-Op (Round 2)

James

Major: Electrical Engineering

I worked on the controls side of a R&D storage machine as well as a semi-automated assembly line for a major manufacturer.

Internship

Alexandra

Major: Political Science

I spoke with clients in Spanish, completed typical office tasks of filing, coping, and mailing. However, I also worked on documents and got a real hands-on experience in immigration law.

Engineering Co-op at Gill Industries

Jack

Major: Product Design and Manufacturing Engineering

During my second term as an engineering co-op at Gill Industries, I continued to gain a wide variety of skills and exposure. I rotated through four week intervals in product engineering, manufacturing engineering, quality engineering, and program management. I was able to design and manufacture prototypes for test fixtures, benchmark competitive products, develop an error detection system on an assembly line, learn how to run machines, and help with quality control. I was even able to collaborate with the other co-ops on small projects.

Small Company, Lots of Experience

Joseph

Major: Electrical Engineering

I usually ran different tests on various products. I maintained lab cleanliness and submitted test reports to the customers. I also typically greeted many customers in the morning and helped them get set up for tests while the rest of the company came to run the tests.

EGR 290 Co-op Experience

Eric

Major: Mechanical Engineering

During my internship at Flexfab, I worked with four other engineers and I had a large role in multiple projects. My first task was to learn daily activities such as quoting, part setups, and how to process engineering change-orders. I was also a part of several large-scale projects. One of the projects I was tasked with was to create a new expander tool for use in the company's 204-4-5 value stream. Flexfab has traditionally used pneumatic expanders, but these have now been deemed obsolete with the inception of the new expander I designed and tested. This project utilized knowledge obtained in both EGR 209 and EGR 309, primarily to ensure that it would stand up to the cyclical loading induced on it by the production line. I also submitted prototype testing requests which helped to familiarize myself with the industries and OEM's specifications.

Co-op Second Rotation

Grant

Major: Mechanical Engineering

This co-op rotation I have spent most of my time designing and modeling in Creo. Design projects began with modeling the crankcase, shroud, and intake system of 3W engine on test for a government contract. I continued my Creo work by modeling a CHP (Combined Heat and Power) system for a private contract. This system included exhaust and coolant heat capturing as well as integrating a turbo generator, forced air heating and charging systems for residential use. My other main project involved many small changes in an existing combustor design for a turbo test cart. This initial testing resulted in a significant redesign that required air flow calculations and part drawings for machining. Initial testing of the components indicated significant improvements over the previous design. Other projects through the semester included stepper motor programming for water flow control to a small dynamometer cart and research and design of an injection rate system to measure the injection volume and injection rate of common rail fuel injectors.

Test Engineering Co/op

Thomas

Major: Electrical Engineering

I ran many tests on specific units and designed new testing processes and software for specific units. Alongside this I worked on developing hardware for a station to run tests on units which involved circuit design and software design.

Test Engineering Co-op: Rotation 2

Collin

Major: Electrical Engineering

I worked in test engineering so I helped support and automate the test engineering processes. Almost all of our products must be vetted before leaving the facility so that was the job I assisted in. There was coding, computer support, and mild schematic analysis involved.

Magna Mirrors Co-op

Danijel

Major: Mechanical Engineering

At Magna Mirrors, I worked along the product engineers with the inside mirror team at the Kraft location. I was assigned many projects that involved aspects such as data collection, testing fixture production, design work, mirror assembly, test planning, and many more. I was given ample responsibilities that exposed me to the pace of a true engineering environment. The inside mirror is such an intricate little piece to a car, it is enjoyable to work with. The design of a simple rear view mirror has changed dramatically over decades, and it is keeping up with the pace of technology bringing many design innovations to life.

Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Kyler

Major: Electrical Engineering

My day-to-day tasks consisted of hardware and software design for various machines. Projects that I was involved with included a laser marking machine, a seat riv-nut insert machine, and a robot spot welding cell. I completed a few programs and electrical schematic drawings along with standard documentation for various machines.

Read More About Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Emerald Corporation 2nd rotation

Peter

Major: Product Design and Manufacturing Engineering

Some of the job requirements that I have include equipment implementation, CAD modifications, data measurement analysis, project development, time studies, capability studies, writing work instructions, and project management of engineering changes. I felt as though I was able to get a wide range of different projects working in different areas of the manufacturing plant. I really got the feel for what Emerald does and what they are capable of doing. One part of my job that I enjoyed the most was getting to do some project management. I was able to manage engineering changes that occurred with current product. This involves; running my own weekly meeting, organizing Engineering change controlled document, and making sure the necessary jobs are done in a timely manner by the team.

IPM Co-Op II - Beyond The Machine

Gavin

Major: Product Design and Manufacturing Engineering

This semesters experience was largely focused on a standardization project for several of our different conveyor product lines. The goals of this standardization project was to ultimately reduce delivery time from receipt of order to commissioning of a line. This required thinking outside of my traditional machine design roll, and focus more on processes and procedure than I would during a typical design process. During the course of this project, I spent a lot of time working with individuals throughout the company in a different capacity than I typically would throughout the course of a project. Aside from completing new equipment designs, I also worked with purchasing agents to develop new ordering strategies, mechanical builders on how to more efficiently deliver the information they need, as well as better equip our sales groups to accurately cost our equipment. I also worked to develop new process documents, libraries and templates, and finally trained my fellow engineers about how to best utilize the program. Once all of these deliverables were met, I helped apply the program to several customers' packaging lines and helped to realize the completion of customer's projects.

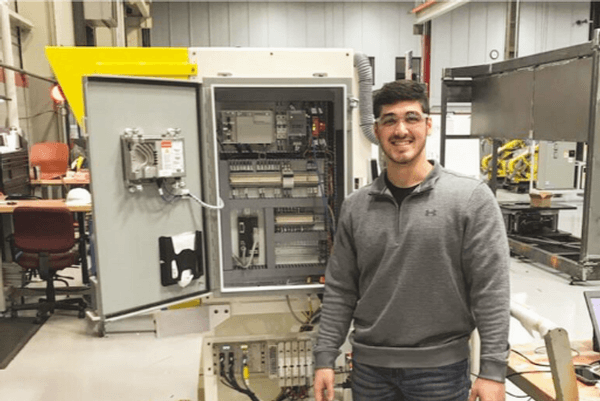

Dematic Co-op II

Collin

Major: Electrical Engineering

Controls Engineering at Dematic consists of determining type and location of various controls devices needed to transport product through a system of conveyors, sorters, and storage systems. It also includes designing the control cabinet. The cabinet contains the switching devices to control motors, as well as the main control device such as a programmable logic controller. It provides power distribution to all conveyor and devices under its control.

Internship

Megan

Major: Advertising & Public Relations

As a Social Media Intern for Grand Rapids After Hours (GRAH), I was in charge of four different venues which included the following: Van Andel Arena, the Intersection, the Downtown Market, and the Tin Can. With those four venues, I was responsible for collecting information on every event that they host(ed) from January to July, and entering that data into our GRAH website for the community to access. I was also in charge of taking my own professional photographs of my venues to add a visually pleasing appeal to the website. Along with my venues, each week I was expected to find 2-3 events in the downtown Grand Rapids area to attend and cover on our three social media platforms: Facebook, Twitter, and Instagram. On top of posting on our social medias, blogging before or after events was expected in order to better resonate with the community and develop our relationship with our growing network list.

Audio/IT Test

John

Major: Electrical Engineering

My co-op focused in two areas: Test Bench Creation & Assisting in Vehicle Tests. Most of my time was spent designing and creating a test bench area that is meant to seamlessly simulate a vehicle's Audio/Infotainment functions (Meter, Head unit, navigation, USB Port, Radio, SXM, etc). By using the test bench, the engineers can perform all software tests without getting into an entire car. Thus saving time and the number of reserved vehicles for the department.

I collaborated with other engineers to design & build a mechanical frame to place all of the equipment. Then, documented/constructed all of the electrical wiring & harnesses that connects each device together to form a complete system.

On another note, each week I acted as an assistant for my co-workers in performing various vehicle tests such as GPS Synchronization, USB Performance, etc.

Interning at Trans-Matic Co-op II

Michael

Major: Product Design and Manufacturing Engineering

My second rotation at Trans-Matic involved: updating 3D cad prints using the Pro-E software, creating drawer layouts for organization of parts, and analyzing functionality of the company for continuous improvement.

Rotations at Trans-Matic have you explore different aspects of the company. Thus no rotation is exactly the same experience.

Congressman Huizenga's District Office

Clayne

Major: Political Science

Being a District Intern came with a number of different tasks/projects. Including; compiling news articles for the congressman and his staff, speaking to constituents both over the phone and in person, aiding the staff in writing congratulatory letters and/or letters of recognition, making sure constituents were directed to the proper case worker to handle their issue, sorting and assigning mail, along with other office duties.

Software Development and Embedded Systems

Christian

Major: Computer Engineering

I got to work on developing GUI applications in Python for integration testing and configuring embedded systems, as well as developing embedded software in C.

Campaign experience

DeMario

Major: Political Science

I worked primarily in fundraising and field operations. I had the duty of gathering donor research and applying that information to a database in which we use to secure funds for our operations. I also was in charge of creating field events for our candidate to speak at.

Co-Op Rotation 2

Robert

Major: Mechanical Engineering

As a Manufacturing and Quality Engineer Co-Op Student, I studied and developed ways to reduce scrap, participated in design projects, capability studies, and other small projects.

Second Co-op rotation

Ryan

Major: Product Design and Manufacturing Engineering

During this second co-op rotation at Yanfeng, I worked in the advanced manufacturing engineering department. Here I helped in launching a new product. In doing this, I participated in many conference calls, meetings with suppliers, and troubleshooting at the factory were the part is made.

JR Automation Co-op 2

Natalie

Major: Electrical Engineering

I spent time this semester doing a few different things. The first thing I worked on was making red-line changes to electrical and pneumatic prints. Next, I set up a vision system to be able to take a picture of a completed part and determine whether is was good or bad. After that, I was placed on a project team and got the opportunity to assist in the PLC programming and creation of HMI screens for a new project. I also spent a little bit of time teaching points to robots.

Mechanical Design Semester

Johnathan

Major: Mechanical Engineering

Most of the tasks I was responsible for during my co-op experience included supporting engineering projects in form of detailing machine designs and checking machine prints for consistency. This was my first co-op rotation in the Mechanical Design department. For this reason I also spent a lot of time learning the CAD software Creo through tutorials and light design work.

West Michigan Whitecaps

Emily

Major: Sport Management

During my time with the West Michigan Whitecaps I have tried participate in as many things as possible. Although, the majority of my time has been spent focused on the Whitecaps Community Foundation Reading Club. This year I was able to grow the program to 322 schools (259 participated in 2017) from the West Michigan area. Students who complete the program during March is Reading Month receive the opportunity to attend a Whitecaps game for FREE! I have also attended mascot appearances, worked in the box office on game days, fulfilled phone and mail orders for tickets using Ticket Return, logged all group ticket orders for the Reading Club, assisted with parking on game days, and of course, pulled tarp.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.