Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-op #1

Luke

Major: Mechanical Engineering

Over the course of my co-op I designed and tested a fully mechanical cell to categorize multiple parts, I assisted in process layout and documentation for new jobs, and I designed and conducted multiple experiments which lead to process improvements and waste reduction.

Environmental Engineering

Nathan

Major: Interdisciplinary Engineering

1) GPS Surveying

Navigation to points

Elevations set to construction grade

Verification of construction grade

Wetland delineation staking

Set construction stakes

2) Instrument Surveying

Drain elevation surveying for WWAT approvals

Surveying to reset staff gauges

Ponds and wetlands

3) Well Sampling / Soil Sampling

Peristaltic pumps, submersible pumps

Field water meters

Static water levels, groundwater contouring, database updates

Profile coring tool for making composite samples for irrigation field testing

4) Reports and Letters

Project updates

Sampling Summary

5) Soils Lab

6) Beneficial Reuse Project

7) Microscope Analysis

a) Frac sand determination

8) Geoprobe

9) Sludge Testing / Application

10) Infiltrometer Testing

Magna Mirrors Co-op Experience

Mitchell

Major: Mechanical Engineering

Over the co-op semester there was a variety of tasks that I was assigned. I was in charge of printing 3D parts off for the advanced product development department (APD) and sometimes this meant my own. I had to clean and de-wax the parts for APD and keep track of the material used. By the end of the co-op semester I was running a variety of tests for the engineers in my department when they needed. Some of the tests included: sound testing in the sound chamber, illuminance scans, vibration tests, working on new prototypes, using Creo to create prototypes, using the instron for load readings, etc. Another main task was benchmarking new mirrors that APD purchased. Benchmarking the mirror involved a series of tests that were documented and organized into a area in the warehouse in bins. It was my job to keep the area organized, clean, and up to date.

Gentex Internship

Matthew

Major: Mechanical Engineering

The Process Engineering group did an excellent job of challenging me as an engineer. They did a great job of finding my strengths and weaknesses and shifting my work to balance my skill-set. Design projects ranged from a few days all the way up to 2-3 months and included tasks such as SolidWorks modeling, Work Orders, Purchase Orders, Project management, Hands-On Assembly, and Implementation. All of the projects were given deadlines either set by a customer within the company or by myself, which allowed me to have a much better understanding of how long a project will last based on the complexity of the design.

Mech. EGR Co-Op I

Travis

Major: Mechanical Engineering

During my time with the company I performed the work of a technician, operating various presses and manufacturing tools in addition to performing validation testing on various mounts.

The Hutchinson Experience

Brett

Major: Mechanical Engineering

Throughout the semester I worked in both the Validation & Prototype labs. In the Validation lab, I tested parts for the engineers on the MTS and the Alliance machines. One of my projects in this lab was to assist in the assembly of one of our fatigue machines. In the Prototype lab I cemented parts, ran our rubber press machines as well as assembling parts and subassemblies. My projects in the Prototype lab included running a study on one of our parts with high scrap and designing a machine that replicates the cement dipping process in production for our prototype parts.

Summer 2015 Engineering Co-op

Zachary

Major: Product Design and Manufacturing Engineering

During the summer I was part of a five man cell that operates an automated assembly machine that produces electrical parts for Haworth office furniture. Daily tasks for the cell included being machine responsible to make sure the machine is running smoothly, daily machine maintenance, machine repair, and design for new machine processes or re-design existing processes. I spent a lot of time working on projects to improve the efficiency of the assembly machine that I worked on as well as a quality check station re-design for another machine in my building.

Magna Co-op #1

Joel

Major: Mechanical Engineering

My projects had a wide range from building, programming, and modifying components of mirror programs to performing vast testing procedures such as impact, vibration, thermal shock, chemical exposure, and function analysis.

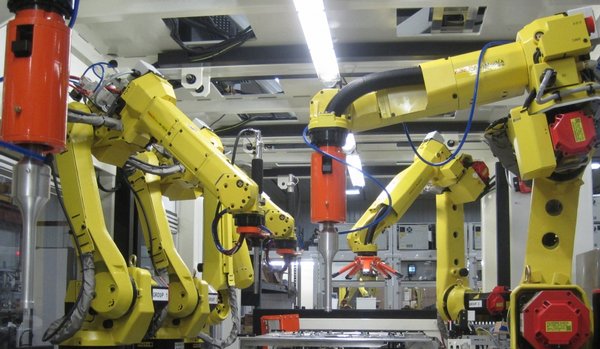

Koops Co-op

Alex

Major: Product Design and Manufacturing Engineering

I did various controls work on several different machines such as PLC, HMI, vision camera and robot programming. Some of the projects I was involved in produced interior car panels, headliners, as well as other automotive interior components. My work lead me on multiple trips to Louisville, KY for install and support of a line I worked on, which was a great experience with the manufacturing industry.

Working and Learning at a Great Company

Isaac

Major: Electrical Engineering

I worked on many projects for different engineers this semester ranging in size and complexity. I worked on schematic updates, PLC programming, circuit design, and circuit building. I also received the opportunity to go to Mexico as a new machine was being assembled there and assist an engineer. It has been a great experience being at Shape learning and working with the engineers here.

ICS, First Co-op

Jaden

Major: Computer Engineering

The tasks assigned were programming in CODESYS and RSLogix software and using these to program PLCs for various projects throughout the US and Canada.

I was also given a project to implement a QR code into one of their visualization solutions. Through this project I learned a great deal about Linux and the workings of the CODESYS program.

Co-op at Corvac Comp

Abby

Major: Product Design and Manufacturing Engineering

I had a few major projects throughout the summer as well as small tasks. My main projects were; (1) Record cycle times of the top 80% of parts based on quantity shipped in order to get a base line standard. Also involved with this project was timing change over times to get a base line for those as well. (2) Layout proposal for the redesign of a cell. The purpose of the redesign was to see how the addition of another trim machine would affect the cycle time of that part.

(3) Running samples of different sheet where regrind material was replaced with reproduced material to see how the different material affects quality of the finished part.

Controls Engineering Co-op

Marshall

Major: Electrical Engineering

This summer, I worked with machine controls, handling electrical drawings and documentation. I set up inputs and outputs in electrical panels and had them installed according to my design. I installed safety features and the electrical systems controlling them. I worked with PLC installation and programming, setting up and modifying the controls that determine how machinery behaves under certain conditions.

Computer Engineering Co-op at JR Automation

Ethan

Major: Computer Engineering

I have been involved in quite a few project which I am not able to discuss in depth. For most of these, I've been doing a lot of programming, mostly in C#, in addition to quite a bit of R&D style work (such as testing and evaluating different hardware). I've also spent a good deal of time on some internal software projects. The one which I have spent the most time on throughout the semester is a program to allow users to change the IP address on multiple network cards at once,

and to track their various settings. I've also spent some time on a set of add-ons to our CAD software which will allow controls engineers to be more efficient and uniform in their work.

In addition to these, I've had several chances to meet with vendors and customers. I've also attended an industry conference about combining industrial and corporate networks on behalf of the company.

Design Engineering Co-op

Alex

Major: Interdisciplinary Engineering

As a co-op student, I was placed on projects that were related to my interest. Due to the diverse make-up of the company in terms to technical and design focuses, I was exposed to a multitude of projects. My work was generally done alone, interfacing with teammates when necessary. I focused in large parts on a testing system for the user interface of a product we were working on for a customer. There was consistent correspondence with the customer as we worked together to identify bugs within the system, pinpoint their causes, and adjust the code to fix them. This was a nice project to work on in that it was nearly instant gratification. When we were able to pinpoint an error in the code, fixing the bug generally didn't take long and the device firmware was quickly updated. One of the more fun projects I completed required me to do a physical build of an office productivity unit; this hands-on project was an incredible change of pace from the research that I was so often assigned and was a great opportunity for me to express my creativity in the prototyping process and iterative stages of the design. Additional projects included an analytical demo project working to develop the company's technological resources for future projects, product benchmarking,

Engineering Co-op 1

Ethan

Major: Mechanical Engineering

I was a part of several projects during the semester that gave me a broad idea of how the entire process of pricing, design, and execution worked. Pricing was an important project because to earn the contract bid from a potential customer it was necessary to address all of their needs while keeping the project as inexpensive as possible. I had the opportunity to participate in phone meetings with customers where I observed how to address the needs of the customer while being realistic about how much we can do. I used AutoCAD to design layouts and the conveyor system, which were used in discussions with the customer about the direction of the project. For another project I calculated the point loads on conveyor supports to ensure that the correct support was being used.

Tool Design Engineering

Marcus

Major: Mechanical Engineering

On the job, my assignments varied from updating part prints to designing new tooling for efficiency and manufacturing purposes. Much of the work I performed revolved around toolmaker requests to improve designs by eliminating time, efficiency, and cost. Some of the most important jobs I completed throughout the semester include: complete tool station redesigns, the modeling of automation assemblies on the floor, and, finally, the designing of new fixtures for the manufacturing of tooling parts.

JR Auto

Adam

Major: Electrical Engineering

As a controls intern at JR Automation I was tasked with a variety of goals and jobs. This could have ranged from computer programming and debugging to swapping parts in and out of a machine trying to find the perfect solution to setting up a camera to accurately analyze a part.

Electrical Engineering Co-op

John

Major: Electrical Engineering

My main focus of this semester was trolling motors, however, I was able to spend a little bit of time in lighting. I soldered and potted boards, working on my coding skills and used a thermal imaging to find hot spots on boards during testing. I also designed an LED board for task lights.

More than just 9-5

Josiah

Major: Electrical Engineering

While at Disher I was able to work on many different interesting projects that I cannot describe to thoroughly. I was able to work with a company that makes car visors, on a project that is meant to redefine how visors are made and installed. I also was able to work on a project for a company that makes smart tables as well. There were plenty of smaller projects as well, but these were the two most important and interesting ones.

A Jack of All Trades

Colin

Major: Product Design and Manufacturing Engineering

I worked in the New Product Manufacturing group. When new products were launched, my group was responsible for spanning the bridge between design and mass production of new products.

My work entailed the design and development of tooling, fixturing devices, and other various manufacturing tools that would make new parts possible to produce.

On top of my engineering responsibilities, I also took part in an intern project with a team of interns with a diverse set of skills. Together, we looked at the way Herman Miller trains and communicates to the people who install the product for our customers. This involved conducting research speaking to business partners involved in selling and putting together the product (dealers and installers). Ultimately, this culminated in a presentation of our proposed solutions to the CEO and executives of the company.

Computer Engineering at Active Inspection

Michael

Major: Computer Engineering

I worked on writing unit tests for various parts of our surface inspection application.

I wrote a couple console applications to further test a couple more difficult algorithms, such as detecting repeating defects in a material.

I added features to our application using WPF and C#.

I tested our application from the UI perspective.

I did a lot of debugging when I found errors to locate and fix them.

Engineering Co-op

Emily

Major: Electrical Engineering

I would split my work into three categories: projects, reports and busy work. Projects were things given to me that took more than a few days. Tasks of this nature occupied about 60-70% of my time. Reports were things that required the acquisition of data, the transformation of raw data, and the actual writing of a report. I had 4 of these within my 3 months at Gill. The last category is busy work. This is the doing of miscellaneous and small tasks. This ranged anywhere from cleaning, to assembling products and this is where the remainder of my time was allocated.

Twisthink Co-op Round 1

Audrey

Major: Electrical Engineering

I did a lot of research on machine learning algorithms for various applications Twisthink is working on, and also wrote some MATLAB functions. I also worked on a detection project, which included determining the optimal sensor for the project's application by researching and then testing. In addition to those projects, I did some temperature testing on several resistors by creating a circuit that simulated what would be happening in the product, and used an IR camera and an oscilloscope to capture the temperature at different time intervals.

Co-op

Jack

Major: Mechanical Engineering

As a launch engineer it was my job to get the machines running from when they were assembled to when they leave to the customer. This involved mechanical, programming, and electrical debug.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.