Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-Op 2

Brianna

Major: Mechanical Engineering

I primarily worked on project management. This included organizing meetings and communicating with customers and suppliers, tracking document status, performing testing, etc.

Second Co-op Rotation at Genesis Seating

Daniel

Major: Mechanical Engineering

During this rotation I was tasked with designing a layout for a cell where a new product would be assembled. This included creating many drawings and ideas for how the cell would be arranged, as well as creating carts and racks to hold different tools and parts that would be used to assemble the chair.

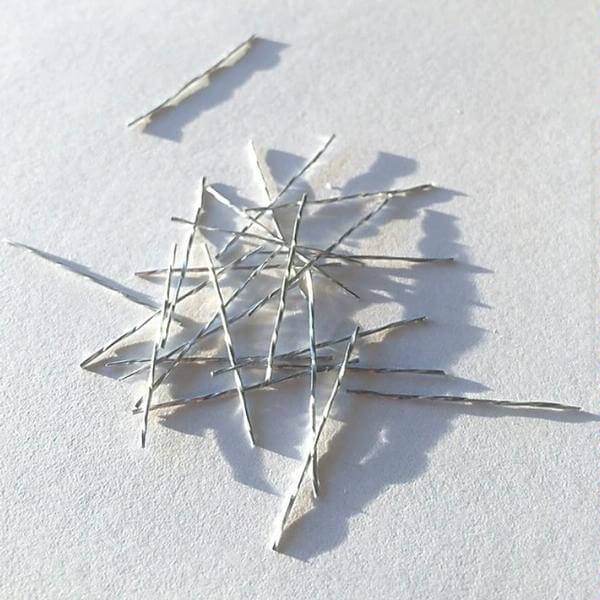

Helix Steel Engineering Co-op

Andrew

Major: Mechanical Engineering

For this semester, I was a machine operator. This meant fixing machine wire breaks, changing wire spools, and pulling and replacing full product boxes from the machines. I also completed excel quality reports for unmachined product and machined product for meeting testing standards and record keeping.

Woodward FST Inc - 1st Rotation

David

Major: Mechanical Engineering

Some of the tasks/projects that I worked on included coming up with new processes to aid in the production of parts. I was also apart of a few CAD design projects to either create new processes or improve existing ones. On a daily basis, the tasks varied to working with different engineers on projects or running with my own project. i also did some shadowing on the floor. There was always lots of collaboration with different engineers and operators and that created a great work environment where new ideas were always encouraged.

390 Co-op

Josephine

Major: Mechanical Engineering

I had launch engineering position this co-op rotation. Launch is our word for getting a machine up and running and ready to ship out to the customer. I worked on several machines, setting sensors, cameras, and flow controls, and testing the auto and manual functions of the machines with customer parts.

DeWys 2nd Co-op Rotation

Zachary

Major: Mechanical Engineering

This semester, I completed a variety of design projects. One of which was a continuation of a previous co-op student's project, where I finalized his design, fabricated the project, and saw it through testing until it was ready to be used to run production parts. I completed various other design and fabrication projects, including designing and fabricating a trash bin lifting system for a trash compactor.

JR Automation ME Rotation 1

Evan

Major: Mechanical Engineering

As a Mechanical Engineer Intern I designed, detailed, and checked my own work as well as others. All Design work was done on Creo and there were plenty of opportunities to learn something new everyday.

Engineering Co-Op rotation 2

Dylan

Major: Mechanical Engineering

I got to develop two new products and an electro-mechanical system.

ENGINEERING CO-OP II

David

Major: Mechanical Engineering

Continuing on through the second co-op rotation, I have mostly been working on new product development and testing with regards to coupler products (Fifth Wheels). I got into more complex projects involving design of new products and inovative designs to decrease cost and weight.

Second Co-Op Rotation

Morgan

Major: Mechanical Engineering

This co-op rotation, I was responsible for the entirety of the programming for the PLC's and HMI's of two machines for two automotive Tier 1 suppliers. In addition, I communicated with customers about the controls and programming of their machines.

A Liftoff into Launch

Joseph

Major: Mechanical Engineering

My primary project this semester was to assist with the deployment of a custom machine to build sub assemblies for automotive components. The machine consisted of five robots, six component feeding systems, vision systems, and a variety of assembly and testing apparatus'.

My duties included:

* Teaching and tuning sensors.

* Verification of machine functions during the machine cycle.

* Fine tuning cylinder positions, robot pick and place positions, and actuator responses.

* Offering feedback to the design and assembly teams for engineering changes and overall project direction and development.

* Assembly and modification of machine subsystems.

* Customer interaction to explain machine functions/modifications.

* Coordination with mechanical engineers and machine shop to get pieces installed in the most achievable time frame.

* Preparing machine for shipment to the customer.

* Verify HMI interactions with operators.

* Wiring modifications and replacing of minor electrical equipment.

* Assure machine was compliant to safety audits and practices.

* Preparation of shipment documentation.

* Fine tuned feeder systems for small parts entering the machine cell.

Other projects that I worked on throughout the semester included:

* A series of ten individual workstations for the assembly of an all electric car console.

* A series of nine individual workstations for the assembly of automotive interior components.

* Shipment prep on a variety of different machine bases.

Advanced Manufacturing Engineer

Eric

Major: Mechanical Engineering

Day to day activities includes quoting, part setup, tooling design, material deficiency report review, and change-order processing. I also managed two projects: one was the acquisition and logistics of a new gas-fired oven (dims: 16ft x 10ft) and the other was the design and execution of a new 10.1 HP lathe. Both pieces of equipment were installed at the M-43 location.

DHBW Co-Op Abroad in Germany at Solar Research Company

Stephen

Major: Mechanical Engineering

I was tasked with the development of a heat chamber. The heat chamber was to reach and maintain certain temperatures in order to measure the emissivity of silicon wafers at different temperatures and angles of measurement.

Read More About DHBW Co-Op Abroad in Germany at Solar Research Company

Co op rotation 3

Natalia

Major: Mechanical Engineering

I worked on a variety of different projects. My main role was to keep track of the scrap parts made during production and learn what caused the parts to be bad and work toward a solution. I was also exposed to supply chain management. I performed audits, took inventory, and learned to use an inventory tracking software. Another responsibility I had was to update and debug one of our machines to improve efficiency. I also helped with 5S and assembled a wiring harness for testing purposes.

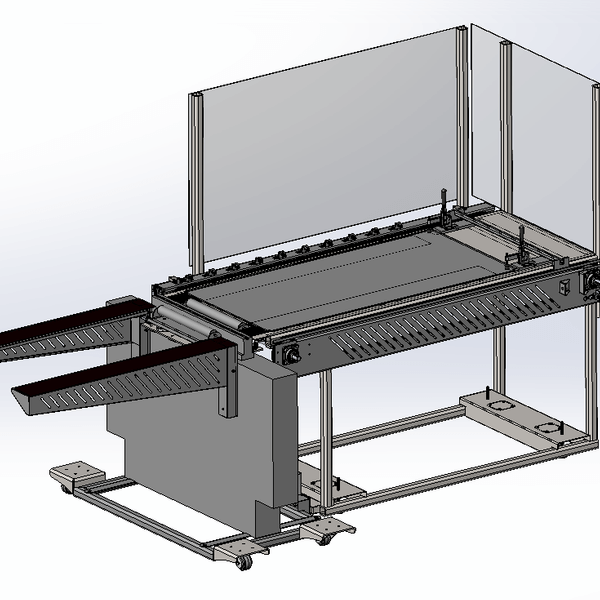

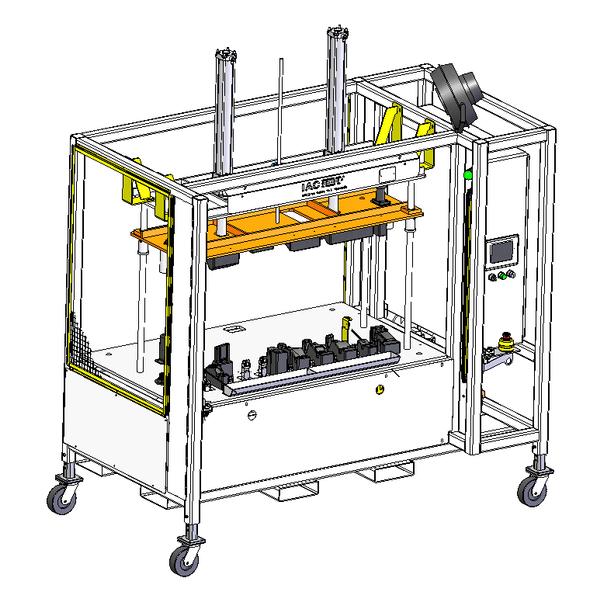

M.E. Co-Op with HS Inc.

Steven

Major: Mechanical Engineering

During my third Co-Op rotation, I played the role of a full-time mechanical design engineer. I was in charge of designing eight different automation machines using SolidWorks 2019. Each machine was designed around a different automated process. These machines were designed to assemble automotive interior parts.

EBW Electronics - Rotation II

Jacob

Major: Mechanical Engineering

Projects consisted of product function tester designs and builds, fixture designs, packaging designs, torque studies using torque transducers, project management, and developing engineering drawings using GD&T.

EGR 490 Co-op 3

Jacob

Major: Mechanical Engineering

Throughout the co-op semester, I worked on several K-12 education, government, and healthcare projects that involved designing new and updating existing mechanical systems (HVAC, mechanical equipment, and domestic plumbing). I was presented with a higher level of responsibility through getting to work on smaller projects from start to finish with the oversee of a professional engineer. An interesting project that I worked on was a snowmelt system that involved using knowledge I learned at GVSU as well as applying practical knowledge from work experience.

Coalescence

Anthony

Major: Mechanical Engineering

I oversaw and assisted with multiple program developments, quality control of parts received, prototype design and manufacture. Furthermore, I was given opportunities to exercise GVSU curricula in ways that fused disparate regions of study.

Applications Engineering Co-op Rotation

Kyle

Major: Mechanical Engineering

My primary role was to develop quotes for automation projects requested by our customers. This involves reviewing specifications, asking questions to further our understanding of the requirements, working with our team to develop concepts, determining costs, and writing technical proposals.

Koops Controls Programming Co-op

Jacob

Major: Mechanical Engineering

During my co-op rotation as a member of the Koops controls programming team my primary responsibility was to program the custom automation equipment that the company produces. The main tasks associated with this were programming PLCs (programmable logic controllers) and the other devices that the PLC interacts with, such as industrial robots, dispensing systems, and vision systems. During the fall semester I had the opportunity to work on two main projects, one of which I was able to work on as the primary controls programmer.

Koops Controls Programming Co-op

Jacob

Major: Mechanical Engineering

During my co-op rotation as a member of the Koops controls programming team my primary responsibility was to program the custom automation equipment that the company produces. The main tasks associated with this were programming PLCs (programmable logic controllers) and the other devices that the PLC interacts with, such as industrial robots, dispensing systems, and vision systems. During the fall semester I had the opportunity to work on two main projects, one of which I was able to work on as the primary controls programmer.

Trane Grand Rapids Graphic's Experience

Tyler

Major: Mechanical Engineering

At Trane Grand Rapids, I was responsible for drawing their floor, hydronic, and air handler graphics using Photoshop. Using floor and mechanical plans, I drew 2-D graphics their customers use to control their HVAC system and what the technicians use to easily fix any issues. I put together graphics orders by going through mechanical plans and control submittals and sent the order to their centralized graphics team.

Intern project

Reuben

Major: Mechanical Engineering

I created work instructions, performed team member training, data analysis, and product development. I worked extensively with a team to develop a product rationalization process - meaning, how to wisely determine which products to discontinue producing.

Super Hands-on

Zachary

Major: Mechanical Engineering

As an intern/cop-op student working with the Innovation team, my job as long as the other engineers job's on the Innovation team was to find any and all ways to improve the manufacturing processes throughout the shop. Whether that be deciding where to put a new machine or relocate a current machine, to designing milling fixtures for various parts, or designing new systems or parts to be used around the shop. I was tasked with a job in pretty much every aspect of the shop. I designed and fabricated a new cart that holds hooks for the powder coating line, designed 7-8 milling fixtures for the automated CNC milling cell, to running a time study and analysis looking at the laser cutting and press braking processes.

Engineering Co-Op Rotation One at Motion Mechanics LLC

Dylan

Major: Mechanical Engineering

This semester I was able to design, build and test. I designed various mounts for a company that we developed a front mount blower for. These mounts adapted to various z-Turn mowers and golf course vehicles. I also was able to go through a prototype build of a floor scrubber and do a lot of validation testing. Whether it was developing mounts or building the scrubbers I was able to do a lot of testing and troubleshooting.

Read More About Engineering Co-Op Rotation One at Motion Mechanics LLC

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.