Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

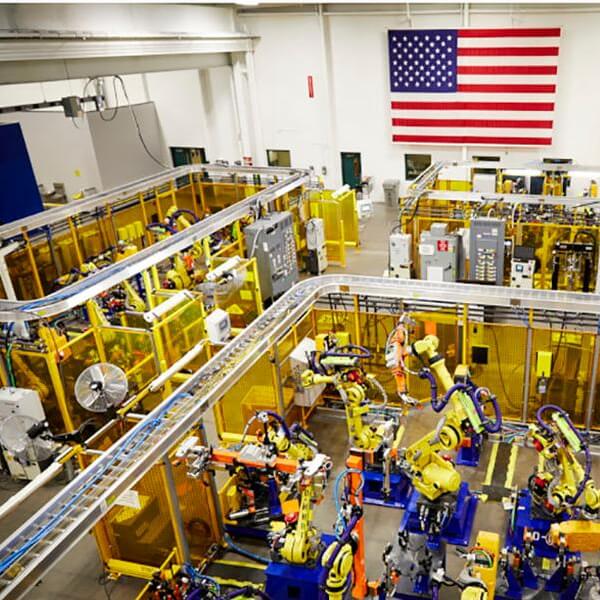

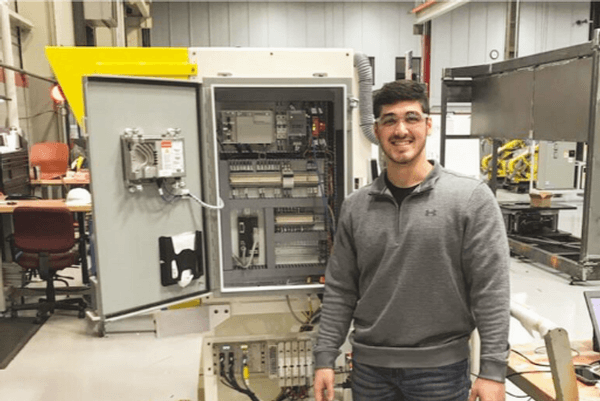

Third Semester Co-Op At JR Automation

James

Major: Electrical Engineering

I mainly worked on prototype projects for a large logistics machine system for our customer.

Experiencing the full spectrum of electronic design

Dongyao

Major: Electrical Engineering

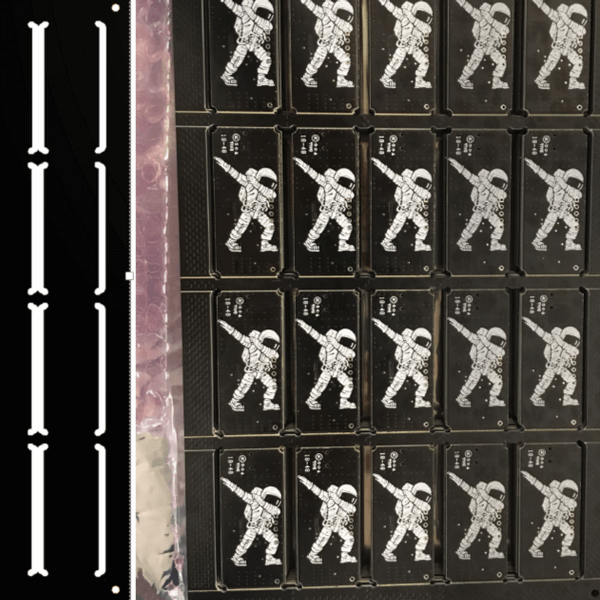

-Designed and built a tester printed circuit board.

-Redesign and built a commercial product (football stadium lighting) with appropriate supervisions and

-Assisted in designing a buck converter for automotive application.

-Assisted in the research and development project with EMI shield.

-Assisted process engineers in validating testers.

Read More About Experiencing the full spectrum of electronic design

Dematic Co-op III

Collin

Major: Electrical Engineering

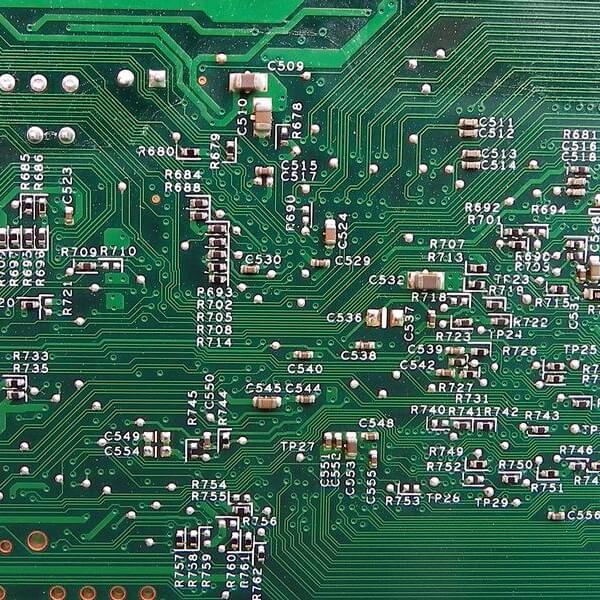

I worked on some PCB layouts for various internal projects in our Research and Development department. I performed testing, validation, and design of several internal products.

Test Engineering Co-op 3

Collin

Major: Electrical Engineering

I worked in test engineering so I helped support and automate the test engineering processes. Much of the work went towards software support specifically. Writing code to fix errors in old software or creating new programs for new testing procedures.

The Final Co-op

Ryan

Major: Electrical Engineering

Designed PLC and HMI programs for two projects, one project consisted of modifications to 3 air handling units and the other was the design of two new air handling units. I also went on a few commissioning trips (Indiana and Virginia) to aid in the commissioning and installation process for these projects.

Software and Hardware Development

Kelly

Major: Electrical Engineering

This semester I got to dive a bit into hardware development. I helped design and prototype a dongle that will be used by Amway. This dongle communicates with existing water and air filters, and technicians will use it to debug issues for customers whom own these devices. In addition, I worked on software development in Python and C for a missile systems project. I also began to gain more FPGA experience through other tasks I was assigned.

Co-op #3 The Final Twist

Christopher

Major: Electrical Engineering

In my previous semesters, I had the ability to work on numerous projects for different West Michigan companies where I learned a lot of valuable skills. However, this semester I had a very narrow focus on a single vision system project. This project included camera evaluation and testing, data set development, and transfer learning algorithms. I was able to utilize a variety of tools in order to complete this project including MATLAB, python-based scripts, TensorFlow and Google's machine learning engine.

Controls Engineering Co-op at

Kyler

Major: Electrical Engineering

My day-to-day tasks consisted of hardware and software design for various machines. Projects that I was involved with included a laser marking machine, a pin-stamping poka-yoke machine, robot end-of-arm-tooling configuration, and a rod crimping machine to name a few. I worked on PLC programs, electrical schematic drawings, and also completed standard documentation for all of the machines along with research and development for upcoming projects.

JR Automation - 3rd Rotation

Natalie

Major: Electrical Engineering

In my third rotation, I was given a lot of individual responsibility. I got the opportunity to write programs as well as teach routes and points for material handling robots. This is what moves parts through the cell to get the automation moving. I also got to create HMI (Human Machine Interface) screens so that operators can interact with the cell. On top of that I got to write logic for the actual operation of the machine and assist with design decisions to best suit the customer's needs.

Engineering Co-op

Andrea

Major: Electrical Engineering

Testing and quality control of device firmware, including the writing and development of automated firmware tests.

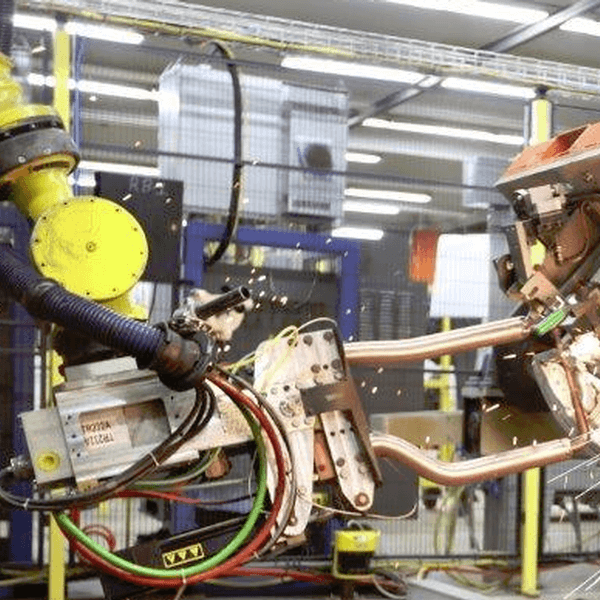

Project Management at Koops

Sam

Major: Electrical Engineering

I was assigned to the project management team, and was able to work on a variety of tasks and projects. I was tasked with my own project to manage, a small cell containing a single robotic unit. This project provided an excellent introduction to project management. I also assisted in working on various other projects, including multiple robotic sonic welding and clip driving stations, and a resistance welding cell.

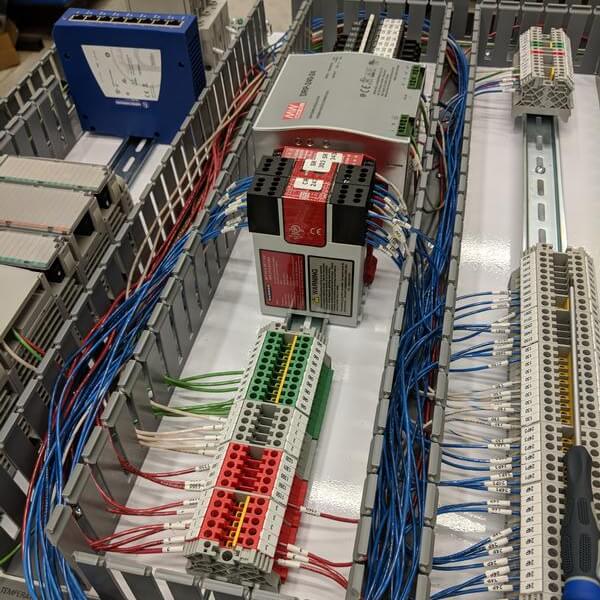

Electrical Controls Systems in Manufacturing

Nigel

Major: Electrical Engineering

I was responsible for keeping wiring diagram drawings up to date with the machines that were on the manufacturing floor. In addition, I did programming and debugging for multiple Allen Bradley PLCs and an HMI (Human-Machine Interface).

Read More About Electrical Controls Systems in Manufacturing

Controls Internship - 1st Rotation

Jaret

Major: Electrical Engineering

My tasks included building control panels, wiring machines, editing electrical schematics, debugging machines, and programming PLCs. I also did some work with a client who needed a secondary HMI display on a few of their machines.

A Summer at Phase One

Benjamin

Major: Electrical Engineering

Buying parts for PCBs.

Construction of several perfboards for demo circuits.

Taking radiation patterns from a PCB with helix antennas.

Making Helix antennas by wrapping copper wire around an high dielectric material.

One big project I did was swapping out a old modem that ran on Verizon's 2G/3G network to Verizon's 4G network. This included getting familiar with AT commands and Mobile network infrastructure.

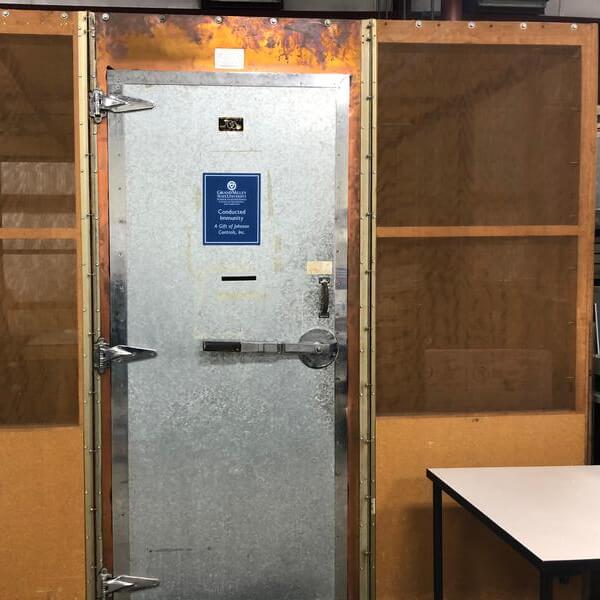

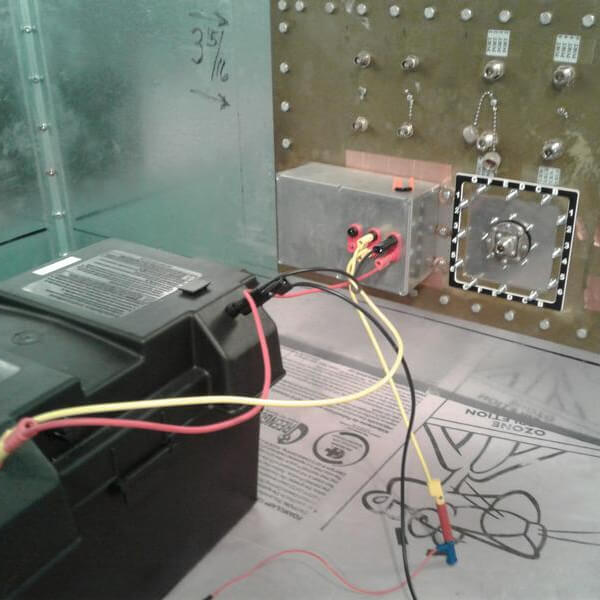

Working in the world of EMC

brittany

Major: Electrical Engineering

I did a variety of tasks, some were day to day tasks which include several types of testing such as radiated/conducted emissions and radiated/conducted immunity. These tests would include working with customers, modifying products, and assessing data. Other tasks completed were long term projects that benefited the efficiency of the lab such as generated lab reports and creating profiles for testing standards.

Herman Miller 2018 Summer

Andrew

Major: Electrical Engineering

Throughout the summer, I've been introduced to a few different types of work at Herman Miller, Spring Lake location. Early on, I started with basic PLC programming using Rockwell software's RSLogix 500. There were a few simple assignments such as mimicking a stoplight sequence and taking the positions of analog sensors. As the summer progressed, my work team lead began assigning me work orders that consisted of issues throughout production. Many of these issues were caused in the PLC programming, whether it be timers that weren't correct, or certain limits that needed to be changed. The most exciting portion of updating the PLC programs is that everything was done online with the controller, so the machines and assembly lines were still running while the changes were being made. Most of the assembly lines and machines are programmed using RSLogix 5000, which is an expansion of RSLogix 500 and offers more functionality to a programmer. Later on in the summer I began working with the HMIs(Human Machine Interface) which are the main interaction between the line workers and the assembly lines. We try to design and program them as simple as possible, while making sure they have maximum functionality. Towards the end of the summer, I started working more with AutoCAD electrical for designing controller layouts and schematics containing sensors, switches, and other components. Along with the wiring schematics, I designed a few control panel enclosures that were later installed for a temporary project on a couple of the smaller assembly lines. The rest of the time this summer was spent working with my project team on the summer intern project. Every intern is placed into a group with 7 or 8 other interns and given a real company issue and the team is to present their solution at the end of the summer in front of the project sponsor, CEO, and many other employees.

Stepping Into The World of Industry

Edward

Major: Electrical Engineering

I was able to design and implement a Heijunka Kanban system for our electronics room. It will help the overall flow of the room and over time help increase the capacity of the room as WIP (Work In Progress) is reduced.

Foundation- Rotation I

Taylor

Major: Electrical Engineering

During my time at Gentex, I was able to work directly on the production floor as a part of a glass fabrication team. Some of my daily responsibilities consisted of servicing quality alarms, helping lead a team, and troubleshooting various issues. I was a member of a team focused on finding the root cause and permanent fix of a quality defect in our product. This consisted of extensive isolation testing, data management, and creating an innovative solution. Throughout my first co-op semester I was also involved in many small continuous improvement projects.

Co-Op 2

Jacob

Major: Electrical Engineering

I worked in the Mechanical Engineering department. I spent my time creating parts, assemblies, and drawings in Solidworks. I often created or modified individual parts for existing machines, but on several occasions I designed groups of parts for larger changes. On some occasions I worked on internal development projects.

Controls Co-Op (Round 2)

James

Major: Electrical Engineering

I worked on the controls side of a R&D storage machine as well as a semi-automated assembly line for a major manufacturer.

Small Company, Lots of Experience

Joseph

Major: Electrical Engineering

I usually ran different tests on various products. I maintained lab cleanliness and submitted test reports to the customers. I also typically greeted many customers in the morning and helped them get set up for tests while the rest of the company came to run the tests.

Test Engineering Co/op

Thomas

Major: Electrical Engineering

I ran many tests on specific units and designed new testing processes and software for specific units. Alongside this I worked on developing hardware for a station to run tests on units which involved circuit design and software design.

Test Engineering Co-op: Rotation 2

Collin

Major: Electrical Engineering

I worked in test engineering so I helped support and automate the test engineering processes. Almost all of our products must be vetted before leaving the facility so that was the job I assisted in. There was coding, computer support, and mild schematic analysis involved.

Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Kyler

Major: Electrical Engineering

My day-to-day tasks consisted of hardware and software design for various machines. Projects that I was involved with included a laser marking machine, a seat riv-nut insert machine, and a robot spot welding cell. I completed a few programs and electrical schematic drawings along with standard documentation for various machines.

Read More About Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Dematic Co-op II

Collin

Major: Electrical Engineering

Controls Engineering at Dematic consists of determining type and location of various controls devices needed to transport product through a system of conveyors, sorters, and storage systems. It also includes designing the control cabinet. The cabinet contains the switching devices to control motors, as well as the main control device such as a programmable logic controller. It provides power distribution to all conveyor and devices under its control.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.