Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-op Third Rotation

Grant

Major: Mechanical Engineering

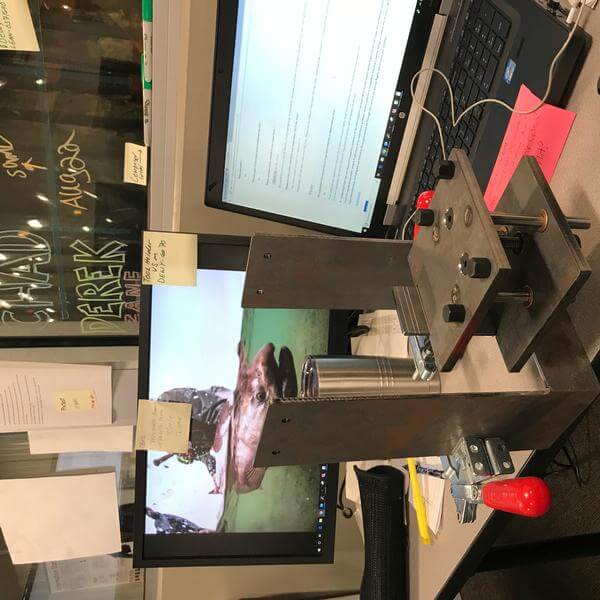

This semester at Baker Engineering I spent my time working on larger, independent projects that I was responsible for from design through to testing. The primary project I worked on was the modification of a hot water tank for the use in an advanced energy recovery system for an engine that we have developed and built in house. This system required extensive structural and layout design, with many design reviews to ensure the final design was as easy as possible to assemble and work on. Another significant project this semester was the design and assembly of a small engine electronic motoring dynamometer. This design presented challenges in both the layout of the system as well as creating a design that was easy to adjust and align the shafts, with minimal run-out on those shafts.

Gentex Co-op III

Dalton

Major: Mechanical Engineering

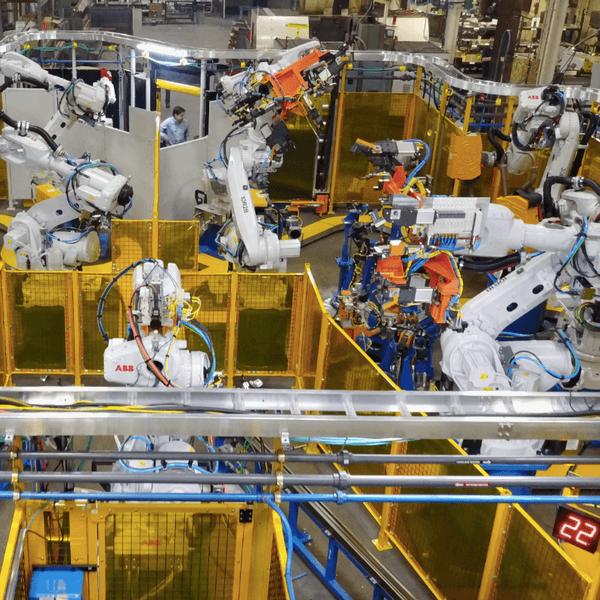

As a production technician, it is always my job to be available in order to maintain the function of the production floor. There are around 12 production lines in our department that produce parts on all three shifts. Each line is consisted of multiple machines that assemble a specific component of the mirror assembly. Each machine usually consists of multiple subsystems. Each system works together with the use of PCs and PLCs to function properly. The machine uses mechanical assembly's and fixtures that are operated by a user with the assistance of sensors and actuators. With this amount of automatic control, the need for constant trouble shouting arises. These systems go down for a multitude of reasons. Problems can arise with vision systems, actuators, motors, cameras, sensors, pneumatics, or mechanical designs. It is the technician's job to make sure these problems are immediately addressed. It is a great experience to be able to apply my engineering knowledge to troubleshoot issues in a fast-passed environment. Doing it yourself with little guidance is the fastest way to learn new skills in this job.

Test Engineering Coop

Thomas

Major: Mechanical Engineering

My work at L3 was focused on Test Engineering and the rigorous testing process which aviation products have to go through. Software work was emphasized as much of the mechanical/ electrical aspect of the design is taken care of by the initial engineering team as the products are designed. Some work was done in aspects of project management as well.

Co-Op Rotation 3

Robert

Major: Mechanical Engineering

The tasks and projects that I completed ranged from troubleshooting machines, to recording data, and managing processes. I spent a majority of my time working with prototype parts, helping the process and ultimately ensuring that the parts are of the highest quality.

3rd Co-op Rotation Experience Summary

Erich

Major: Mechanical Engineering

In my third rotation the tasks I completed include the following: prototype design, that includes CAD, FEA, and hands on fabrication; FEA for various products; visits to suppliers; and physical testing of new ideas and product designs.

Header and Hanger

Tyler

Major: Mechanical Engineering

This semester I was assigned with a senior engineer on a specific project. He put me in charge of designing a header and hanger system. This system supports conveyor by suspending them from the ceiling. This allows for additional conveyor to run underneath. The goal was to design components that will safely hold the conveyor with the maximum conveyed load. Part drawings were made and sent to fabricators to make the necessary components. Installation drawings were made with labels for the correct parts and dimensions to tell mechanical installers where to put the components in the building. Finally, assembly drawings were made to show the installers how to put the components together.

Controls Programming At Koops

Max

Major: Mechanical Engineering

The projects I was given were PLC based, which is programming via ladder logic. A task given to me was to offline code machines; this is creating the general structure of the machine and how it processes inputs and outputs. Another task of a controls engineer at Koops is to debug machines, which required working with the PLC and the hardware of a machine to create create an operational PLC.

Open doors to a Bright future

Luis Enrique

Major: Mechanical Engineering

In my time at Axis, I wanted to be part of the different department along with my three co-op rotations. My first semester with them I was mainly working on the factory floor with the workers and reporting directly to one of the project managers. On my second rotation, y was part of the Design department, this is where I wanted to stay the most time since the work was more interesting and the relation between the designers, factory floor workers, project managers, and customers was interconnected. Basically, I was able to know what was going on everywhere and suggest changes to anything.

This is where I found the most interest inside the company other from the project manager position that I wanted to be part of, but this was not possible since a project on the automation industry could take more than 1 constant year of work and I was just there 1 semester at a time making this opportunity almost impossible.

Mechanical Design

Johnathan

Major: Mechanical Engineering

This co-op semester I worked as a mechanical engineer at JR Automation Technologies. The majority of my tasks were related to one project. The project involved designing an automated machine to assemble industrial A/C compressors. When I joined the project the design was nearly 100% complete. Most of the engineers that were working on the project left to work on others. I became responsible for supporting the build team and dealing with any issues that came up during the build process. I designed some of the guarding around the machine and added sensors where needed. I redesigned some machine components when issues came up on the build floor with components that were not working as planned. I met with the customer to discuss changes they wanted to make to the machine that were not brought up in the original design meetings and processed an Engineering Change Order for their requests. Other mechanical engineers, controls engineers and machine builders taught me a lot this semester, I have gained tons of practical experience during my time at JR Automation.

Final Co-op Rotation

Bruce

Major: Mechanical Engineering

The two project that I worked on most were improvements to an existing product as well as the launch of a new product. I was around for the entire design phase for the new product.

'Controlling' the HVAC Industry - One Building at a Time

Anthony

Major: Mechanical Engineering

My co-op rotations were spent working with the contracting department. This department is contracted to building owners to install Building Automation controls. Once our sales department wins a job, the contracting department takes over the project management, engineering, installation, and programming of the controls. Specifically, I was/am involved in the engineering of this process. The engineering consists of creating Control Drawings for the installation and programming phases of the jobs. The Control Drawings show our electrical subcontractors and control technicians what controllers are going to be used throughout the job and what end devices / equipment are going to be used in the Building Automation System.

Read More About 'Controlling' the HVAC Industry - One Building at a Time

Ravenna Ductile Iron Co-op III

Spencer

Major: Mechanical Engineering

This semester, I worked with RDI's engineering team completing a large variety of tasks. These tasks included: cleaning and inspecting casting tooling, designing casting tooling, evaluating performance of said tooling, and determining appropriate solutions to any problems found. A major project completed was a redesign of several high volume tools to improve yield and decrease costs.

Hutchinson NA Coop 1

Stephen

Major: Mechanical Engineering

Although this was my first official coop, I worked at Hutchinson NA last summer as an Intern. This gave me a huge advantage going into my coop semester because I had already completed all of my lab and safety training the year before. I was able to jump right in, working closely with engineers for projects for well known companies including Ford and GM. My primary role was designing fixtures for cementing, the process for preparing components to have rubber adhere to them, assembly, and testing of parts. I used SOLIDWORKS to design all of these fixtures.

Herman Miller Green House

Stephen

Major: Mechanical Engineering

I was assigned a section of the factory for which I was responsible. As a manufacturing engineer, my job was to make the operators job faster and easier. I solved day to day problems as well as working on long term projects. A few projects I worked on were prototyping a design a vacuum lift assist device, designing a unique tool using modeling software, and managing departmental moves.

Engineering Co-op

Kyle

Major: Mechanical Engineering

Throughout this summer i have done work on many gages for many different customers. Each gage is assigned to a specific experienced builder and i had the chance to help the builders complete gages by either machining parts for the gage or assembling the gage with them. I also had the opportunity of working in our CMM lab (Coordinate Measuring Machine) where i was able to measure the final stage of the gage to make sure that gage met our customers standards before we sent the final product to them.

Hutchinson Engineering Co-op

James

Major: Mechanical Engineering

Tasks and projects given were extremely varied and well rounded for an entry level internship. Working through different departments such as the characterization and prototyping lab then being tasked to assist with manufacturing and pre-production approved cells to create parts was the majority of my co-op experience. There were intermittent projects given to perform jobs such as designing shielding for machines, modifying parts for tuning purposes, and preparing display pieces.

(Injection) Molding My Future

John

Major: Mechanical Engineering

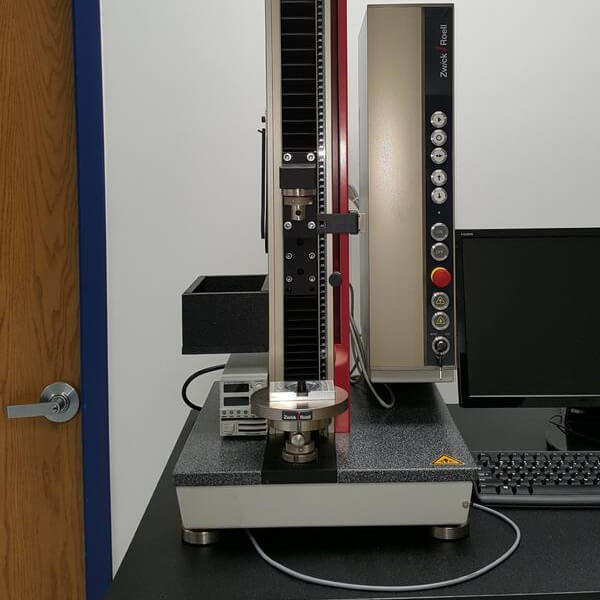

I was directly involved in the testing and developing of a new part for production. This included testing prototypes- both dimensionally and for performance, performing durability tests, assembling parts, and working with my supervisors to recommend changes. My primary duty was carrying out all testing of parts, writing reports on my findings, and then working with my supervisor to identify design and process changes that were necessary. I also was involved in the production of most sample parts produced during my time there. I worked on multiple different molding machines for different components of the part, did coil winding, welding, and final assembly of components. I also completed several projects related to documenting both critical dimensions of new components in our database and creating instructions for quality inspections, testing, and production.

Co-op Rotation I

Kyle

Major: Mechanical Engineering

During my first rotation at Trane, I worked to create graphics for projects in which the engineering work was recently completed. These graphics include floor plan, air handler, and water system graphics. It was also my job to check in parts that were ordered by the engineers and ensure everything that was ordered had arrived.

Engineering Co-op, Koops Inc.

Joseph

Major: Mechanical Engineering

My co-op time in Koops was spent in the Business Development team and was split into two distinct sections: Sales and Applications.

In Sales I was introduced to the company, our structure, organization and products. I learned to be the front face of the business presenting customers with solutions for their manufacturing needs. Doing site visits, taking phone calls, and responding to website leads were part of my jobs. The most major project I undertook in Sales was an email campaign to revitalize old customer leads with whom we had lost contact. More than three hundred emails later and I am still responding to healthy sales leads.

Applications taught me how to quote a project. When a customer sends us a request for a quote it's the job of the applications team to put together a comprehensive, itemized list of parts, components and manpower necessary to complete it. Quoting involves a certain level of engineering creativity to discern the most efficient, feasible and economic solution to each problem.

Mechanical Engineering Co-Op Experience

Austin

Major: Mechanical Engineering

Tasks at HMC has a large range. Tasks include, SolidWork designs for new or improved tooling, data collecting and excel work, and hands on technical work. The main focus of my rotation was in the foundry. Creating new processes and improvements to increase productivity.

Yanfeng Automotive Interiors Intern

Ann

Major: Mechanical Engineering

For this summer internship I was placed in the Advanced Manufacturing Engineers Department under Dale Boone. My mentor was Laura Snyder and I have been working closely with Joel Timmer on the DJ IP Trim Line that is being sent down to Mexico, 34 machines. For the IP Trim Line, I developed ODS (Operator Description Sheets) for the DJ IP Trim assembly line, assisted in creating a Poka Yoke Matrix for the different sensors on the machines and updated the PFMEA (Process Failure Mode and Effects Analysis) spreadsheets. I built parts for our different builds, evaluated the control plans and proved out equipment to send to Mexico. I also worked on my own project, proposing to replace our current peel and stick labeling process with a more advanced and efficient laser marking process.

Co-op Semester #1

Connor

Major: Mechanical Engineering

At Cascade, I have worked on the floor to become more familiar with the operators and the manufacturing methods as well as worked in the office to learn more about engineering in the real world. I have done maintenance projects on our office's 3D printer, created ergonomically friendly production work cells, and have assisted engineers on molding tryouts on several projects.

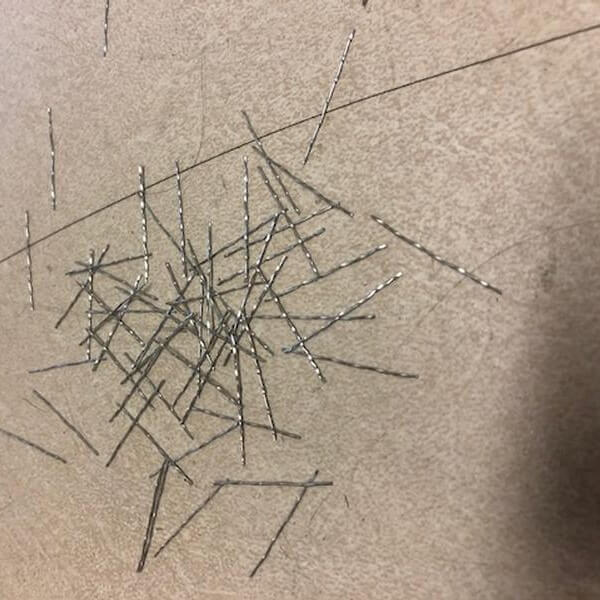

Quality and Machine work at Helix Steel

Andrew

Major: Mechanical Engineering

Wrote quality reports which took different tests regarding overall product strength and dimensions for both new and finished product. Also worked and performed maintenance on machines that ran our 8 mm wire. Helped start a new chute design project designed to reduce floor scrap, saving time and money.

Co-Op 1 Summer 2018

Chad

Major: Mechanical Engineering

The team that I was officially on was the innovation team. This meant that we focused on ways to improve what was going on in house, that could mean helping improve quality, helping improve how machines run and taking employee suggestions on how to make things around the shop better. This semester I designed a couple of carts that will hold the waste from the paint line when parts are powder coated. This barrel can come close to 500 lbs. before the barrel needs to be emptied. Another project that I worked on was a system that would use a PLC to open a lid to one-inch container when the parts in the anywhere are to be used.

First Co Op Rotation

Natalia

Major: Mechanical Engineering

I worked on projects ranging from labeling tools, to assembling an electrical plug, to designing supports using CAD software. I also had the responsibility of keeping the work area clean and organized.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.