Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

More than Recycling

Ryan

Major: Mechanical Engineering

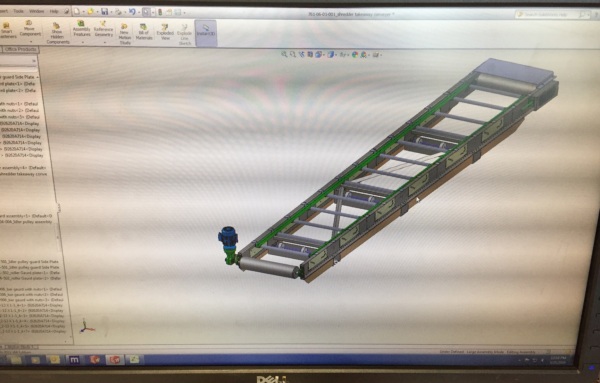

The tasks I was required to complete during the semester I worked at Padnos were very diverse and unique from each other. This was because the engineering department is only 4 full time engineers with 1 co-op student. They service all of the locations with recycling equipment on site. This means there is a lot of work and modification that need to be created by the department as well as new innovative processes and machines that also need to be designed. I had a lot of responsibilities in larger projects such as a new plastic recycling line was being put in I was required to take charge of designing and overseen the fabrication of multiple components of the system including conveyors and pneumatic sorting fingers. I also did many small tasks called "continuous improvements" that are ideas submitted by operators of machinery or other employees that give ideas of how to make a process more efficient, safer, or just maintenance that needs to be completed. These ranged from adding operating platforms to making safety bars to hold up a machine component when maintenance was being completed. I had many unique tasks that each brought their own challenges because every one had to do with a different process and had different requirements because of it.

Mechanical Engineer Co-Op 1

Patrick

Major: Mechanical Engineering

Benchmarked various automotive parts such as outside and inside mirrors. Design work with a 3D printer for prototyping parts. Designed displays for automotive parts created by Magna as well as other automotive companies. Conducted light, sound, vibration and impact studies of automotive parts.

Consumers Energy Low Voltage Distribution Co-op

Tyler

Major: Electrical Engineering

Projects assigned to me ranged from electric distribution line planning, concepts and designs.

Tasks required for these projects included many detailed drawings, creative designs, technical calculations and accurate cost estimates. Other tasks required customer communication, and coordination with electric construction operations.

In addition, I had the opportunity to tour many different Consumers Energy facilites that introduced me to other company operations such as the Webber Dam Hydro Plant, Ludington Pumped Storage, and J.H. Campbell Coal Plant.

Read More About Consumers Energy Low Voltage Distribution Co-op

Michigan Women's Foundation Internship

Mara

Major: Integrative Studies

I completed administrative tasks such as; creating a Doodle Poll, generating purchase orders, utilizing Donor Perfect, and answering/making phone calls.

I also completed substantial research on a potential organization merger with national implications

Co-op 1 at Autocam

Joe

Major: Mechanical Engineering

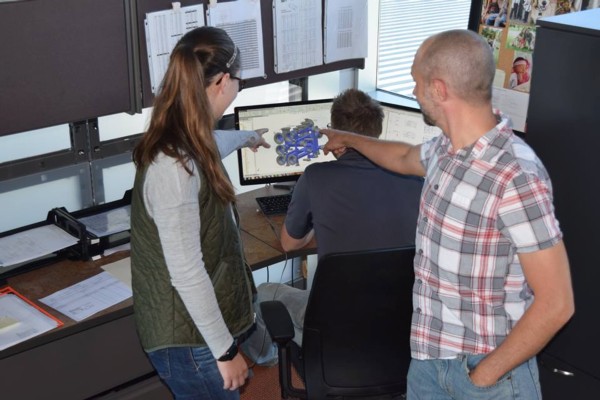

Many of the most successful engineers and managers at Autocam started their careers by operating machinery. For this reason, I spent the first half of my summer in a machinist and lab technician role. I was trained and gained operational certification for a CNC multi-spindle lathe as well as a multi-spindle screw machine. Both of these machines manufacture components for gas direct injection fuel pumps in high volumes and with high precision. I also performed first piece inspections using various gauges and lab equipment. Some of this equipment measured surface finish, surface profile, and roundness, capable of measuring fractions of nanometers. The second half of my summer was spent working in the engineering department. I assisted with research and development for a new Autocam part. I designed and performed studies to monitor critical dimensions at various stages in the product's manufacturing cycle to identify points in which problems are occurring. I also performed a gauge correlation study where I compared results from various measurement devices to identify the most efficient gauging method for accurate, automated, 100% inspection. I assisted with the assembly of an automated work cell and learned about how robots and vision systems can be used to inspect critical features and dimensions.

2016 Meijer State Games of Michigan

Julian

Major: Sport Management

I worked with the Meijer State Games of Michigan as their Vendor Coordinator. My job was to bring in different organizations/businesses to be apart of our Opening Ceremonies event which kicks off the games. After about 50 days of preparation for the games, we worked the opening ceremonies event and assisted each sport to help make the Summer Games a huge hit!

Spartan Fund Internship

Chris

Major: Sport Management

I was responsible for donor prospect research, reaching out and thanking donors, answering phone calls, updating personal information, and helping out in any other way that the team needed. My three months here were a very busy time for us because we run on a fiscal year from July 1st - June 30th. I also did a lot of administrative work to help keep our office from falling behind. This work included folding thank you letters, stuffing envelopes, creating new donor packets, scanning in pledge forms, and doing mail runs.

Expat Community Center Internship

Nicholas

Major: International Relations

Since The Spot is new, it needs to get its brand out there. I was in charge of marketing at The Spot. My job was to let expats know about what we had to offer The Spot. My usual tasks included posting on social media, organizing and promoting events, writing blog posts, managing web content and SEO, and attending expat networking events.

JR Automation Rocks!

Mike

Major: Mechanical Engineering

I completed automation quotes on a daily basis. Each quote takes anywhere from one day to three weeks. I dealt with vendors on a daily basis, and many different JR Automation employees as well. I organized meetings for quote reviews, and helped to organize and attend customer meetings as well. The very first quote that I worked on, lasted for a month and a half and was finally sold for more money than I ever thought I'd be involved with.

Experience at TwistHDM

Kyle

Major: Electrical Engineering

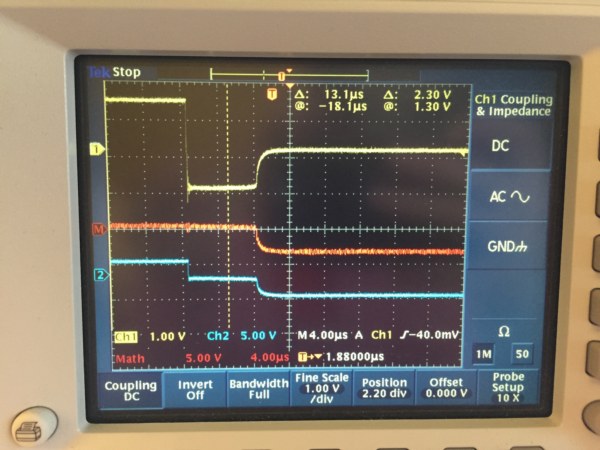

Validation for a new generation of our controls circuit involved a large amount of electronics testing equipment under temperature extremes, voltage surges, and many other "what-if" situations to ensure the product is bullet-proof. This also included fine-tuning of component values and the code accompanying it, applying external modifications, and actively looking for issues and addressing them as we go.

RF signal analysis using spin-testing in various configurations.

Root-cause analysis of components that failed in the field and working with manufacturing to address the problems.

Analysis of sensor effectiveness in various climates using Python scripts to interface with data sent from our controllers.

Supporting the engineers: applied many intricate mods to boards which involved cutting & re-routing PCB traces and replacing small surface-mount components.

Design ME at JR Auto

Jatinderpal

Major: Mechanical Engineering

During my time at JR I designed stations for assembly lines, modified existing assemblies, and detailed and checked design prints.

Royal Technologies - Plastic Injection Molding

Dylan

Major: Product Design and Manufacturing Engineering

The theme for my summer at Royal was "learn the company from the ground up". I accomplished this by learning a variety of positions. The coop started with me working as an operator and then quickly becoming a scanner/auditor. I was then moved to the utility position where I got to change molds on the injection presses and learn more about how the presses worked. A supervisor role brought more chances for troubleshooting issues and learning more about team management. Later I moved to assembly and assembly supervisor. Time studies and management were used to help maximize efficiency.

Read More About Royal Technologies - Plastic Injection Molding

Engineering Internship at Rose Medical

Bridget

Major: Mechanical Engineering

At Rose Medical I worked on a lot of documentation, fixture calibrations, prototype testing, and actually manufacturing products.

Dornerworks First Rotation Co-op

Kevin

Major: Electrical Engineering

I was taken in as a hardware engineer co-op and thus all my tasks were hardware focused. I was task with making most of the board modifications for the lead engineers on the project team. I was also put in charge of functionality and performance testing of the many different circuits located on the customers PCB. This involved obtaining and setting up software to control specific signals and verify that the circuit functions as expected on both an analog and digital level. Also, I had to introduce the boards to worst case scenario options and verify that the designs did not fail. If the designs did fail it was my responsibility to help diagnose the failure and verify the the correct changes were made in consultation with the lead engineer. I spent most of my time in the lab working with oscilloscopes, DMM, and other electronic tools during the verification. I was also put in charge of the mechanical testing of the design in which the PCB boards would be enclosed in. This project involved exposure with the external customer and other engineering companies.

Experience of a lifetime

Sarah

Major: Computer Engineering

Throughout six weeks as an intern, I have completed 5 projects :

- Update GVSU It Department's Wiki page

- Implement bootstrap to web pages

- Detect illegal characters from file names and alert the user

- transfer data from XML files to an Oracle Database

- Apply JQuery and JQuery Ajax to JavaScript functions.

Summer Co-op

Chris

Major: Electrical Engineering

I worked with the office group to help design prototypes, repair and maintain part testers for the production floor, worked with Altium to design schematics and board layouts. I also made testers for ITW so they could test some of the boards we sent them. Along with working with the office group I also helped out the production floor with creating test fixtures and programming and testing parts.

Electrical Engineering Co-op 1

Nicholas

Major: Electrical Engineering

Most of the tasks and projects that were completed included C programming, hardware testing, and the interaction between software and hardware. Test engineering is important for keeping manufacturing error to a minimum.

MFP Automation Engineering Co-Op Semester

Brianna

Major: Mechanical Engineering

I spent time in our production shop learning basic shop practices including milling, welding, making hoses for power units, testing the units, as well as prepping for paint. During my time in engineering, I gained more experience with AutoCAD for our 2D drawings of power units. With more part familiarization, I was able to begin quoting my own projects.

Cascade Engineering Co-op

Sara

Major: Mechanical Engineering

I worked in the CFI (center for innovation) department where most of the engineers are located. However, much of the work for my projects required me to go to other plants on the campus to view either parts or the work cells for different machine presses.

I worked mainly on two projects, however I did help with some other testing studies as well. One of my main projects was designing and building an inspection table for one of the machines. The boxes of parts would sit on the table to make it easier for the supervisor of the press to inspect the parts. This project helped me gain a lot of problem solving skills as the project was almost entirely self led.

The other main project I worked on was helping create a tool for some of our customers. Our trash containers get shipped out in stacks of 10 and often are hard to pry apart. There was already a tool in place that helped de-stack these containers, however, it was not very user friendly. Along with another engineer, I helped create a new tool that is much more user friendly to de-stack the containers.

Internship at Fox Hills Golf and Banquet Center

Kyle

Major: Sport Management

I was responsible for helping with setting up the various golf outings that we had at the course. Once the outing or tournament was completed, I assisted with scoring the events. As league coordinator, I helped with scheduling leagues and collecting league payments from all the golfers that made up the individual leagues. As Director of Junior Golf, I was able to communicate with parents and participants about league schedules and rules. I was able to help and organize both the junior leagues and the adult leagues so that they were able to play every week throughout the summer.

Read More About Internship at Fox Hills Golf and Banquet Center

Co-op

David

Major: Mechanical Engineering

I have spent a majority of my time working on the architectural mechanical systems in universities throughout west Michigan including GVSU. I have designed, commissioned. and coordinated the mechanical systems that help buildings operate efficiently and conserve energy.

Intern

Hripsime

Major: Sport Management

I am working with the YMCA inner city baseball/softball program. I have done everything and anything that is needed of me. I go to fields and make sure everything is running smooth, I pass out food to kids, I register kids, I update rosters, and I recruit players and coaches.

Mechanical Engineering Co-op

Jordyn

Major: Mechanical Engineering

Throughout the summer I was able to work with several departments in order to complete order entry tasks, cost analysis drawings using AutoCAD, order-completion drawings, and drawing modifications. I also had the opportunity to travel to Mexico for two weeks to aid in part identification. All of these tasks helped further my knowledge of products within the company as well as how to use different programs in order to properly complete my job.

MHSAA Intern

Kevin

Major: Sport Management

Daily responsibilities and skills will be handling daily correspondence, insurance planning, officials training, tournament scheduling and policy writing

Engineering Co-op

Ryan

Major: Product Design and Manufacturing Engineering

Tasks include print creation for sales and production purposes. Includes quality checking and some product development

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.