Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Interning at LG

Connor

Major: Mechanical Engineering

At LG I was put in charge of the crating process which sent material to another one of our factories. Also, I worked on safety improvements to some of the roll press machines to get rid of pinch points operators run into. Also I assisted on a project that used Tekscan software to use a pressure sensor to determine the wear of the roll press and the many sub rollers on the machine. Finally, I added adjustable feet to a table. This allowed for the Tesa measurement device to take more accurate measurements by leveling and stabilizing the table.

Hutchinson Co-op

Nick

Major: Mechanical Engineering

-Prototyping Lab production

--Testing and creation of Rubber parts to have the correct properties of the rubber/plastic

-Validation Lab

-- Testing of multiple parts for characterization and properties of the fluid in said parts

--Multi-directional ultimate testing

-GM Team

--Fixture Creation

--DFMEA creation

--Design improvement

--Development meetings

Integrated Packaging Machinery Co-op experience

Brody

Major: Mechanical Engineering

As a Co-op student at IPM, I did a lot of computer aided design in programs like Solidworks and AutoCad. I had the opportunity to work on real projects with sometimes very custom solutions and problems which I had to work through with members of the team. Overall, I felt as if I was a functional member of the engineering team at IPM and not just an intern.

Read More About Integrated Packaging Machinery Co-op experience

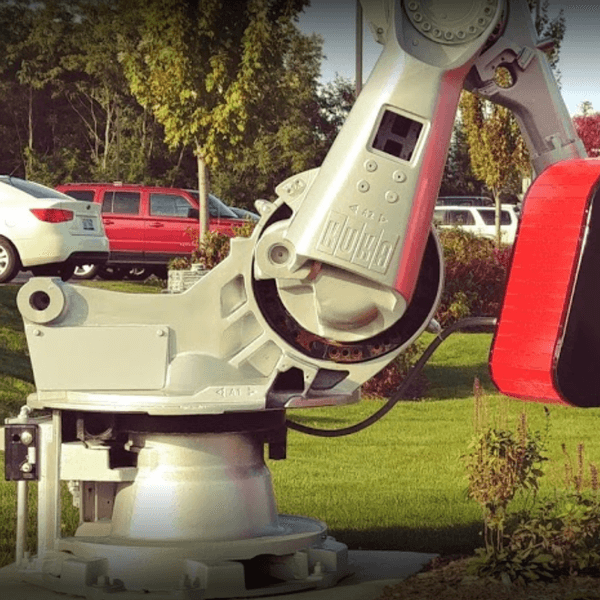

Magna Co-op

Zakary

Major: Mechanical Engineering

Throughout the course of a semester, I put to use my skills learned in classes to help improve on the design of a robot used for cycling. I was also able to help with determining how parts would fit together for a new mirror as well as complete multiple kinds of testing to determine if the mirrors were meeting required standards.

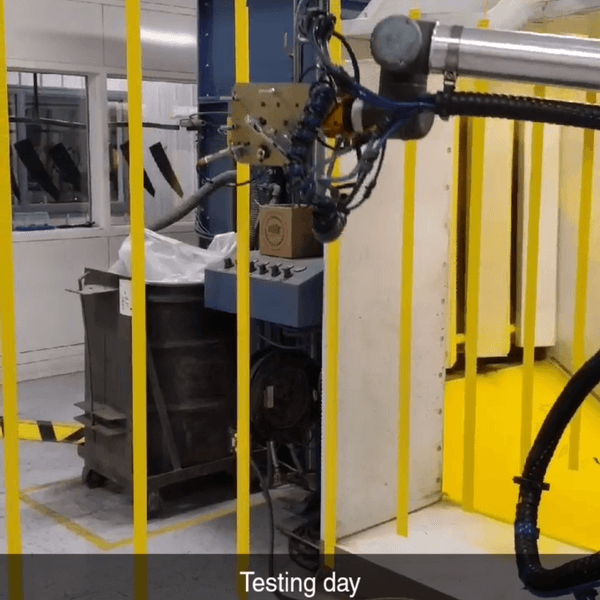

Axis Automation Second Co-op

Mason

Major: Mechanical Engineering

This semester I worked on a variety of projects on the back end of the design process. This consisted of detailing prints for parts and assemblies, redesigning and updating existing designs, verifying robot loads, and evaluating robot and fixture interaction.

Co-op Student at RDI - Semester 1

Andrew

Major: Mechanical Engineering

The first half of each day began by cleaning, inspecting, and organizing the pattern plates that were recently ran. During this time, various other tasks could come up including shipping out or receiving patterns, stamping unmarked patterns, and watching a sample run for a modified or new pattern.

The second half of each day usually consisted of various jobs on the CAD program Creo. I reverse engineered patterns on transfer tools and created new tools from scratch. Molten iron flowing through the created patterns was simulated in a program called Magma. These simulations were then used to make modifications to potential new patterns as well as improvements to existing tools.

Magna Mirrors Co-op Experience

Joshua

Major: Mechanical Engineering

I did a variety of tasks. Much of my time was spent in preparation for engineering builds for prototypes, studies, etc. This required me to gather mirror components and arrange for time to be spent on the line. I also performed studies/gathered measurements. This usually came in the form of dimensional measurements, reflectivity measurements, angle measurements, and Instron measurements (pull-out strength, for example). I also had several longer term assignments, such as designing a portable "suitcase" tester for a new video mirror, and a role in producing, testing, and statistical analysis of mirrors built with experimental aluminum tubes (replacing steel).

Third Co-op Rotation

Jordyn

Major: Mechanical Engineering

I analyzed customer verbatim and complaints, benchmarked competitors, and made possible recommendations to improve customer satisfaction

DeWys Manufacturing Co-op

Zachary

Major: Mechanical Engineering

In my final co-op rotation, I worked mainly on a project which sought to add a collaborative robot to the powder coating line on-site to help with quality issues of the powder application. I did lots of CAD design and planning, and the build and testing will be happening shortly. It was overall a great semester and I learned a lot from the experience.

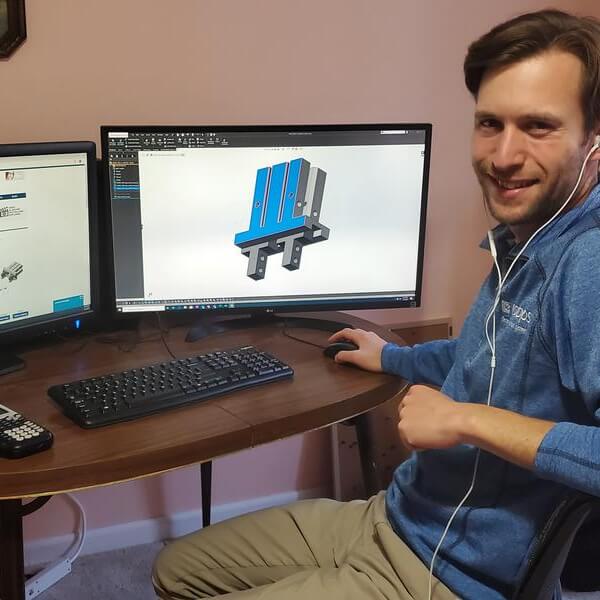

IPM Mechanical Engineering Co-op #3

Logan

Major: Mechanical Engineering

I was tasked with various degrees of project work, where I designed, modeled, and assembled hundreds of parts to form a specified conveyor for the application at hand. I also worked on standard library components to help improve efficiency for designing in future similar projects.

Final Co-op at Medical Device Manufacturer

Emily

Major: Mechanical Engineering

Being my third co-op rotation at Rose Medical, I had the opportunity to work on more challenging and complex projects. I worked mostly independently on protocols-- drafting, receiving customer approvals, executing, and writing reports. The nature of these were for installing new tooling/fixtures, updating tooling, manufacturing process qualifications, operational (verifying machine settings for various products) qualifications, measurement system analysis validations, and numerous customer requested validations. The vast majority of these were for two projects with two project engineers at Rose Medical; I reported to both for the duration of the semester. I also was given the opportunity to run my own project for a company requesting prototypes of a tipped cannula. For this, I was the point of contact for the customer. I created a schedule, designed four fixtures/tools for the tipping process, got quotes for tooling, and placed orders for tooling and material. The project reached a bump in the road with ordering the customer specified material with the customer ultimately changing material; therefore, I didn't get to create any prototypes. Instead, I learned bounds and leaps more by this hiccup through difficult communications than if everything had gone smoothly. In addition, I was a point of contact on one of my supervisor's projects where I sat in on meetings and communicated daily with the customer, answering questions and providing recommendations. By doing so, I kept the project's rapid pace while my supervisor was out of the office and aided getting product out the door during crunch time. I executed multiple DOE's for different products to recommend settings for thermal welding, medical pouch sealing, and cannula bending processes to multiple engineers.

Engineering Co-Op rotation 3

Dylan

Major: Mechanical Engineering

I started off the semester doing a robotic welding fixture for a local manufacturing company and then I went more into product development, specifically with landscaping tools and power equipment.

Engineering Co-op Final Rotation Experience

Abbey

Major: Mechanical Engineering

I spent the semester mostly designing and detailing parts and assemblies using PTC Creo software.

EGR 490: Co-op 3

Ryan

Major: Mechanical Engineering

During my co-op, my main responsibility was to execute projects that improve upon our manufacturing processes. Some larger projects included redesigning/refreshing major components of our machines. In addition, I was also responsible for a portion of the day's production, materials handling, preventative maintenance, and spare parts management.

Quality Engineering Co-op at Flexco

Austin

Major: Mechanical Engineering

There were a wide variety of tasks that I completed. I was able to complete multiple solidworks composer animations of product assemblies (they are used as a reference for the shop floor). I also spent time writing work instructions that explained how parts went together in assemblies. A considerable amount of my time at Flexco was spent inspecting, sorting, or salvaging parts.

Regular Employee

Beau

Major: Mechanical Engineering

Project engineering at TGW puts all of the puzzle pieces together and orders anything todo with mechanical install. After the project is sold and the preliminary design is done Project engineering takes the project and does more detail engineering for the entire project. Some of the major items that we handle are mezzanines, fencing, safety, stairs, racking, and large portions of conveyor like sorters or cranes.

EBW Electronics - Rotation III

Jacob

Major: Mechanical Engineering

During my final co-op rotation, I was able to be much more independent by heading projects on my own. I contributed to many mechanical engineering designs and analyses associated with new product launches. I was also able to perform finite element analyses to determine thermal strains associated with heat generated from new LED assemblies.

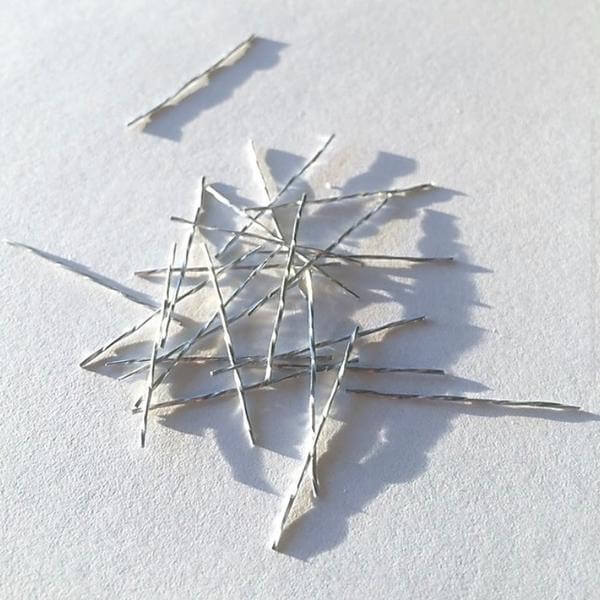

Helix Steel Engineering Co-op

Andrew

Major: Mechanical Engineering

This semester I was a machine operator at the plant. This meant doing routine tasks like quality checks, restringing machines, and preventative maintenance. It also included diagnosing machine and quality issues and learning about how to fix those issues in a time-efficient manner.

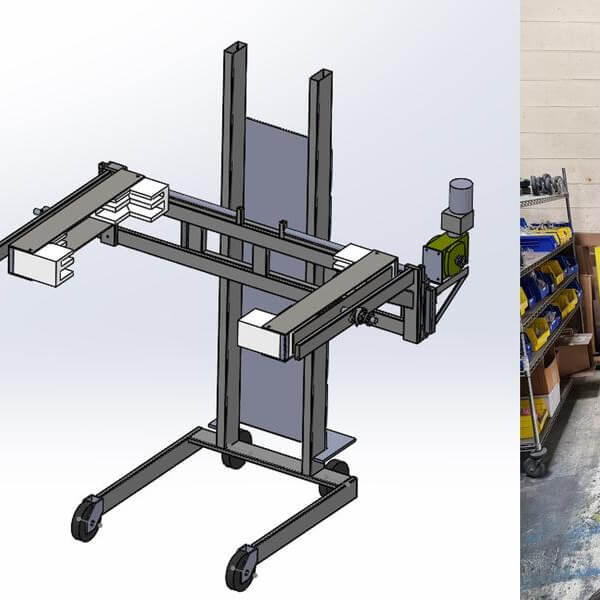

Engineering Co-op at Genesis Seating

Daniel

Major: Mechanical Engineering

This was my third rotation, so many of the projects I worked on were larger than previous rotations. Last semester, I created a proposal for a portable lift which would be used to raise and lower sofas from an assembly table. This rotation my main project was creating this lift. However, it now needed a rotational function lift rotate and lower 200 lb table tops without damage. This was completed by modifying a portable pallet stacker to meet our needs. I designed every component of the lift in SOLIDWORKS and used this design to create the lift.

EGR490 Co-Op III

Malcolm

Major: Mechanical Engineering

I often worked directly with customers to understand their needs and desires of the projects. I drafted project specifications and qualification protocols. I often had a hand in the manufacturing processes as well.

Co-op III @ Gentex Corporation

Chadwick

Major: Mechanical Engineering

While at Gentex, I was given the opportunity to work on some awesome projects with the aerospace group making auto dimming windows. I was able to work on process improvements for our Boeing 777X product, improve epoxy materials to protect the electro chemistry in the window, apply statistical analysis to the manufacturing process to identify high impact projects, and a multitude of other projects. I was able to be hands-on with the product and processes for much of my work.

Co-op Rotation 2

Jake

Major: Mechanical Engineering

At IPM I was given many opportunities to learn about business, conveyors, and CAD. At IPM i was able to work with AutoCad and SolidWorks every day. Hands on experience for me is extremely important and IPM was a perfect learning opportunity and a great co-op decision.

EGR 390 Co-Op Rotation

Jordyn

Major: Mechanical Engineering

I worked with the design team. My duties include supplier parts test support & closure, design issues support & closure.

Cooped Up at Koops

Daniel

Major: Mechanical Engineering

During my rotation I modified the design of an overhead cage for use in assisting the assembly process of vehicle headliners. During this project, the design was reviewed, prints were drawn, and a bill of materials was created and kicked off. After Kick off, I had the opportunity to build the cage I had designed to experience some of the issues that could come up in the assembly process when not caught by the mechanical engineer.

Later in the semester, I worked on a team designing stations in an automation cell that assembled vehicle components. Design reviews were held twice a week to try to keep things on track for kickoff. This involved a lot of problem solving and team work to try to meet customer specifications and keep costs down.

EGR 390 Co-op experience

Greg

Major: Mechanical Engineering

For this rotation, I was assigned to the quoting department. I would put together full quotes that would be sent out to customers for potential work.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.