Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

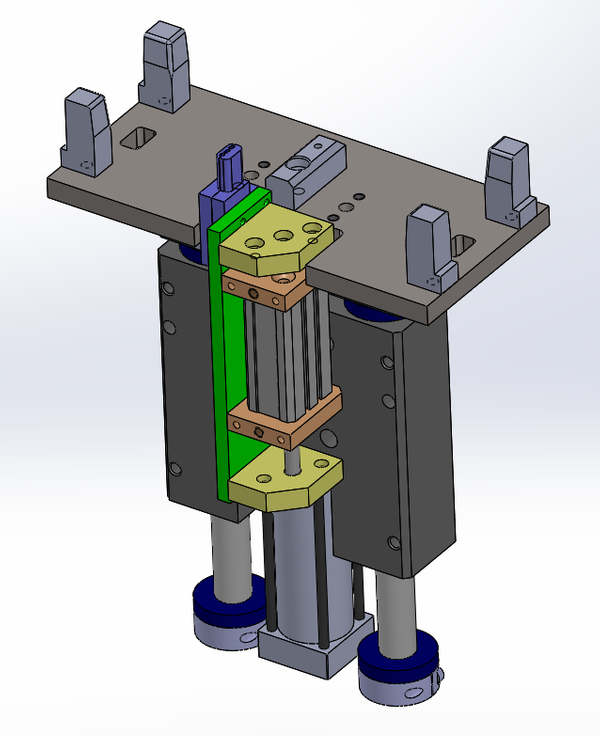

Controls Engineering for Automation

Benjamin

Major: Mechanical Engineering

I worked as a controls engineer on several major projects, primarily handling the programming aspects. My projects included a hydraulic edgefold press (in picture) and a medical packaging inspection and placement system. I was the primary person responsible for making the machines execute their operations properly and for making any number of minor changes on request.

Engineering Co-Op Semester at Flex

Lukas

Major: Mechanical Engineering

During the semester at Flex i assisted the engineering team in assembling solenoid prototypes to be tested in simulated vehicle transmissions at the Ford motor company prototype testing facility. I was taught how to read and analyze force and pressure output curves in order to tell if a part was good or bad. I also learned how to fix parts and troubleshoot malfunctioning testing equipment in order to get satisfactory force and pressure curves. In order to continue builds in the semester i learned how to use machining equipment so i could modify solenoid assembly components for further testing. I partook in a daily meeting with the engineering team where we discussed what was accomplished the previous day. Lots of engineering conversations took place to meet customer specifications which helped me gain a lot of experience in root cause problem solving.

JR Automation Co-Op

Gunnar

Major: Mechanical Engineering

As a quoting engineer my responsibilities included concept development for customer, creating a budget/estimate of cost for the cell, and customer communication. This job really combined the design side of engineering with the customer interaction required when selling a product to a customer.

Haworth Engineering 3rd co-op

Colton

Major: Mechanical Engineering

I worked on many projects that included quality control, new product development and product enhancement. I helped to document and design several parts for a new product. I was also able to help in the testing of product.

Cell Lead for Automation Company

Kyle

Major: Mechanical Engineering

Managed an automotive line that built an overhead lighting component that went into 3 different vehicles.

Presented daily efficiency reports and monthly reports.

Designed components for new projects and upgrades on the assembly line.

Managed projects and production schedules.

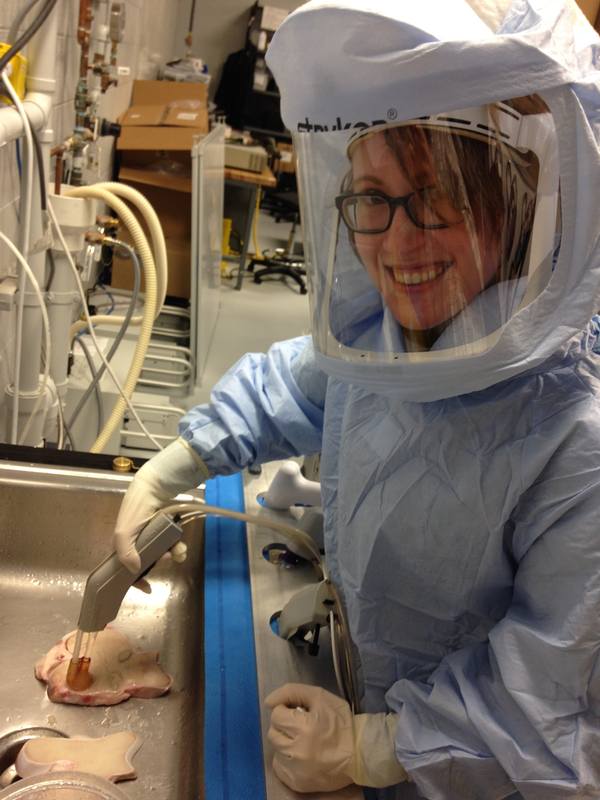

Mechanical Design Engineer

Caitlyn

Major: Mechanical Engineering

While working with Patient and Caregiver Safety Team, I was able to have three main projects. I was able to design and build a voice of customer light fixture, a head adjustment system for the surgical helmets, and researched and built prototypes of several designs for the disposable product line.

Mechanical Engineering Coop at Gentex

Derek

Major: Mechanical Engineering

My primary task at Gentex this semester was to support production lines as issues arose. I worked mostly on technical and mechanical malfunctions of the machines. Not only did I support the lines to keep them running, I worked at increasing quality, safety, and productivity in my projects.

Mechanical Engineer Co-op 3

Michael

Major: Mechanical Engineering

Designed and built multiple displays, designed lab test equipment, designed and built prototypes of potential products.

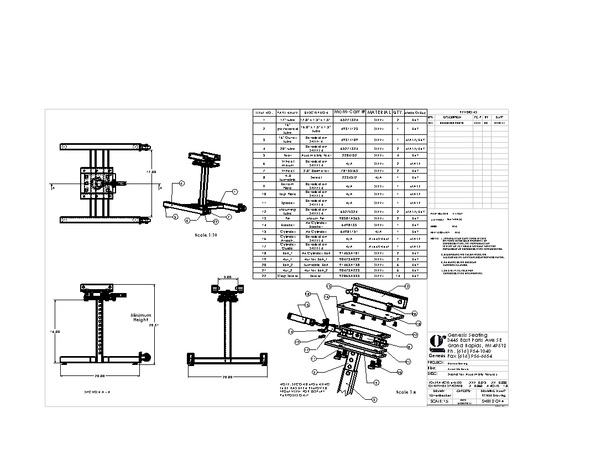

New Product Development

Leif

Major: Mechanical Engineering

I have worked more on the new product development side of Genesis Seating during this rotation. This means that I've been involved in the construction of prototype models for testing and also been involved in enhancing old designs. In creation of new products we, as a manufacturer, need work instructions and control plans on these products, so I've been involved in the creation of those. I've sat in on multiple meetings with customers in discussion on the progress of changes made to existing chairs. I've also been involved in the design and fabrication of work fixtures.

Manufacturing Engineer Co-op at Bosch Emission Systems in Germany

Chris

Major: Mechanical Engineering

I worked as a planner in the MOE1 department (Manufacturing Operations and Engineering). I helped plan the equipment, working sequence, layout, documentation, and helped solve daily problems within the various manufacturing areas on the floor. I worked on making the manufacturing line more lean using lean line design tools and implementation.

Read More About Manufacturing Engineer Co-op at Bosch Emission Systems in Germany

Trans-Matic Experience

Reid

Major: Mechanical Engineering

Working as an intern for the engineering department I completed a wide range of tasks. I managed engineering drawings for a new product launch. I developed a new tool to aid in tool setup which allows the toolmakers to use a comparator (measurement device) to establish tolerance profiles of the part after each stamping process. I used SolidWorks FEA to analyze a prototype side piece assembly post. I also completed Engineering Change Requests of gauges and part prints. I updated tooling drawings and models based on toolmaker feedback. I redesigned stamping stations to include things like ejector pins, spring sleeves, and higher tonnage chucks. I aided in the design of a geared assembly and recommended design changes to customers for ease of manufacture and measurement while keeping design intent. These recommendations were implemented by them.

Innotec Mechanical Engineering Experience

Zachary

Major: Mechanical Engineering

During this semester I ran production, worked on machine improvement projects, and repaired machines. One of the machine improvement projects I lead was an improvement of an automatic nail machine by adding an encoder, and designing/building a chute that can redirect too short or too long nails down a separate scrap chute to reduce the risk of non-conforming parts being sent to the customer.

BISSELL Mech. Engineering Co-op

Tony

Major: Mechanical Engineering

I was on the Product Attributes team (sort of R&D), so I wasn't tied down to working on any specific product. For example, this term I designed a test/test fixture for analyzing torsional stiffness of deep cleaner handles. I also wrote an excel macro to automatically summarize data for one of our tests. I also created a calculator tool in excel to solve a FBD system for the drive wheel suspension in our robot vac.

TowerPinkster

Alec

Major: Mechanical Engineering

I designed the mechanical systems for buildings ranging in multiple market sectors (including healthcare, commercial, governmental, K-12, and higher education). This included designing HVAC and plumbing systems, 3D building modeling in the AutoDesk Revit software, and producing building documents for use in construction.

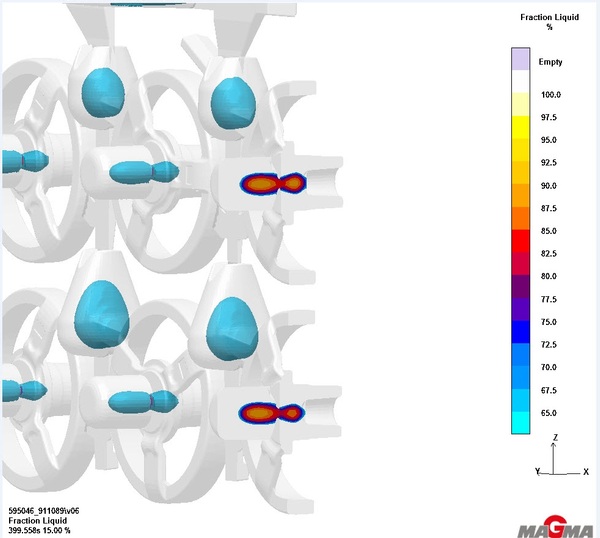

Semester 3

Eric

Major: Mechanical Engineering

3D design of new patterns, replacement patterns, reverse engineering of old tool.

Daily pattern inspection, clean-up, storage.

Sample Traveler Program, Weight Traveler Program.

Gauge Design and Procurement.

Wafer Core Project Design and Procurement.

Cost and Concept Development Co-Op at JR Automation Technologies LLC

Jonathan

Major: Mechanical Engineering

I was a Concept and Cost Development Intern for the summer in which I worked with several engineers of various knowledge bases to design concepts with CAD and cost the concept accordingly. The job not only entails critical thought and thinking outside the box in literally every situation but also developed my thought for legal business practice. Writing a quotation is extremely difficult and demands covering all of ones bases so that when something comes up down the road, the company isn't out thousands of dollars. Not only was I required to write these quotes, but also act as a salesman of the product I was designing a concept for as well. No one will buy what you are designing, if you can't stand behind it and back up what you were thinking. On several occasions I held and led meetings with department heads, business unit managers, VP of sales, and even the CEO at one point.

Read More About Cost and Concept Development Co-Op at JR Automation Technologies LLC

Co-op #1

Luke

Major: Mechanical Engineering

Over the course of my co-op I designed and tested a fully mechanical cell to categorize multiple parts, I assisted in process layout and documentation for new jobs, and I designed and conducted multiple experiments which lead to process improvements and waste reduction.

Magna Mirrors Co-op Experience

Mitchell

Major: Mechanical Engineering

Over the co-op semester there was a variety of tasks that I was assigned. I was in charge of printing 3D parts off for the advanced product development department (APD) and sometimes this meant my own. I had to clean and de-wax the parts for APD and keep track of the material used. By the end of the co-op semester I was running a variety of tests for the engineers in my department when they needed. Some of the tests included: sound testing in the sound chamber, illuminance scans, vibration tests, working on new prototypes, using Creo to create prototypes, using the instron for load readings, etc. Another main task was benchmarking new mirrors that APD purchased. Benchmarking the mirror involved a series of tests that were documented and organized into a area in the warehouse in bins. It was my job to keep the area organized, clean, and up to date.

Gentex Internship

Matthew

Major: Mechanical Engineering

The Process Engineering group did an excellent job of challenging me as an engineer. They did a great job of finding my strengths and weaknesses and shifting my work to balance my skill-set. Design projects ranged from a few days all the way up to 2-3 months and included tasks such as SolidWorks modeling, Work Orders, Purchase Orders, Project management, Hands-On Assembly, and Implementation. All of the projects were given deadlines either set by a customer within the company or by myself, which allowed me to have a much better understanding of how long a project will last based on the complexity of the design.

Mech. EGR Co-Op I

Travis

Major: Mechanical Engineering

During my time with the company I performed the work of a technician, operating various presses and manufacturing tools in addition to performing validation testing on various mounts.

The Hutchinson Experience

Brett

Major: Mechanical Engineering

Throughout the semester I worked in both the Validation & Prototype labs. In the Validation lab, I tested parts for the engineers on the MTS and the Alliance machines. One of my projects in this lab was to assist in the assembly of one of our fatigue machines. In the Prototype lab I cemented parts, ran our rubber press machines as well as assembling parts and subassemblies. My projects in the Prototype lab included running a study on one of our parts with high scrap and designing a machine that replicates the cement dipping process in production for our prototype parts.

Magna Co-op #1

Joel

Major: Mechanical Engineering

My projects had a wide range from building, programming, and modifying components of mirror programs to performing vast testing procedures such as impact, vibration, thermal shock, chemical exposure, and function analysis.

Engineering Co-op 1

Ethan

Major: Mechanical Engineering

I was a part of several projects during the semester that gave me a broad idea of how the entire process of pricing, design, and execution worked. Pricing was an important project because to earn the contract bid from a potential customer it was necessary to address all of their needs while keeping the project as inexpensive as possible. I had the opportunity to participate in phone meetings with customers where I observed how to address the needs of the customer while being realistic about how much we can do. I used AutoCAD to design layouts and the conveyor system, which were used in discussions with the customer about the direction of the project. For another project I calculated the point loads on conveyor supports to ensure that the correct support was being used.

Tool Design Engineering

Marcus

Major: Mechanical Engineering

On the job, my assignments varied from updating part prints to designing new tooling for efficiency and manufacturing purposes. Much of the work I performed revolved around toolmaker requests to improve designs by eliminating time, efficiency, and cost. Some of the most important jobs I completed throughout the semester include: complete tool station redesigns, the modeling of automation assemblies on the floor, and, finally, the designing of new fixtures for the manufacturing of tooling parts.

Co-op

Jack

Major: Mechanical Engineering

As a launch engineer it was my job to get the machines running from when they were assembled to when they leave to the customer. This involved mechanical, programming, and electrical debug.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.