Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Fogg Co-op Experience

Zachary

Major: Mechanical Engineering

Fogg kept me very busy right from day one whether they were teaching me about Fogg's procedures and standards getting me started with some work. I did a lot of revisions in the beginning of my co-op. These revisions were a good way for me to wade my way into the water. I learned a lot of things on SolidWorks through these revisions as well as being exposed to all the different ways of accomplishing the same goal. These revisions also helped me to learn names and faces of the engineers at Fogg. If I got a print that asked for a change of the part, I would go seek out the engineer that drew the part and had to check with them to make sure that the requested change wouldn't affect the part in a negative way. I also created a couple fixtures to hold a part in a specific orientation to allow for welders to create a consistent part. During my time at Fogg I have also received miscellaneous tasks here and there when they pop up. One of these tasks was to work with one of the electrical engineers to design a cable tray bracket. While not a large or complicated design I had a sense of accomplishment after creating the bracket.

More than Recycling

Ryan

Major: Mechanical Engineering

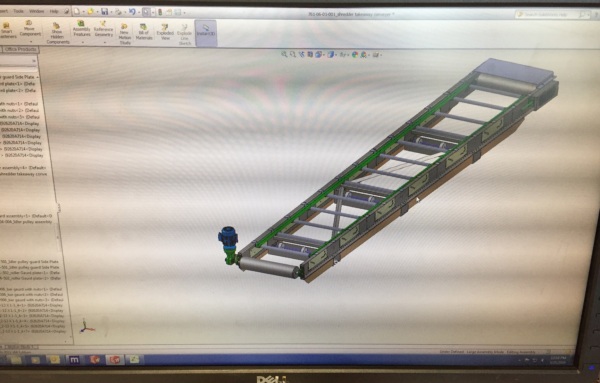

The tasks I was required to complete during the semester I worked at Padnos were very diverse and unique from each other. This was because the engineering department is only 4 full time engineers with 1 co-op student. They service all of the locations with recycling equipment on site. This means there is a lot of work and modification that need to be created by the department as well as new innovative processes and machines that also need to be designed. I had a lot of responsibilities in larger projects such as a new plastic recycling line was being put in I was required to take charge of designing and overseen the fabrication of multiple components of the system including conveyors and pneumatic sorting fingers. I also did many small tasks called "continuous improvements" that are ideas submitted by operators of machinery or other employees that give ideas of how to make a process more efficient, safer, or just maintenance that needs to be completed. These ranged from adding operating platforms to making safety bars to hold up a machine component when maintenance was being completed. I had many unique tasks that each brought their own challenges because every one had to do with a different process and had different requirements because of it.

Mechanical Engineer Co-Op 1

Patrick

Major: Mechanical Engineering

Benchmarked various automotive parts such as outside and inside mirrors. Design work with a 3D printer for prototyping parts. Designed displays for automotive parts created by Magna as well as other automotive companies. Conducted light, sound, vibration and impact studies of automotive parts.

Co-op 1 at Autocam

Joe

Major: Mechanical Engineering

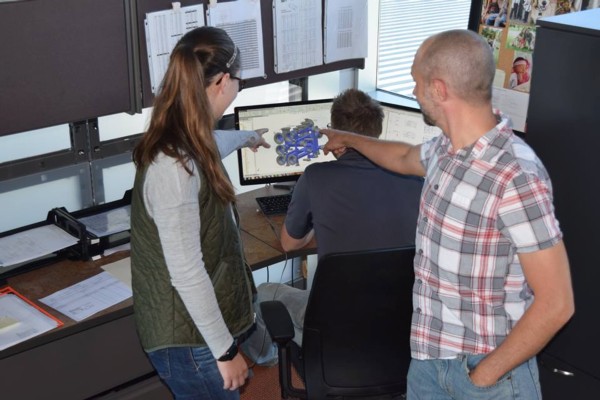

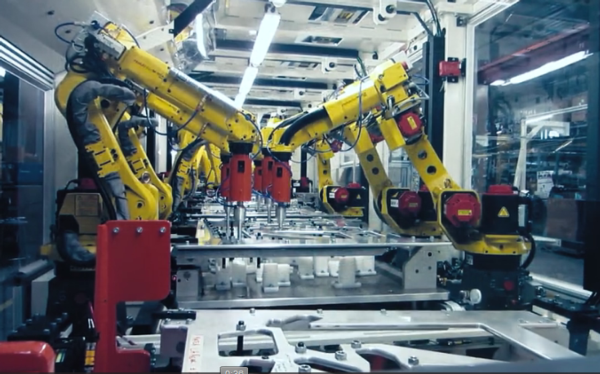

Many of the most successful engineers and managers at Autocam started their careers by operating machinery. For this reason, I spent the first half of my summer in a machinist and lab technician role. I was trained and gained operational certification for a CNC multi-spindle lathe as well as a multi-spindle screw machine. Both of these machines manufacture components for gas direct injection fuel pumps in high volumes and with high precision. I also performed first piece inspections using various gauges and lab equipment. Some of this equipment measured surface finish, surface profile, and roundness, capable of measuring fractions of nanometers. The second half of my summer was spent working in the engineering department. I assisted with research and development for a new Autocam part. I designed and performed studies to monitor critical dimensions at various stages in the product's manufacturing cycle to identify points in which problems are occurring. I also performed a gauge correlation study where I compared results from various measurement devices to identify the most efficient gauging method for accurate, automated, 100% inspection. I assisted with the assembly of an automated work cell and learned about how robots and vision systems can be used to inspect critical features and dimensions.

JR Automation Rocks!

Mike

Major: Mechanical Engineering

I completed automation quotes on a daily basis. Each quote takes anywhere from one day to three weeks. I dealt with vendors on a daily basis, and many different JR Automation employees as well. I organized meetings for quote reviews, and helped to organize and attend customer meetings as well. The very first quote that I worked on, lasted for a month and a half and was finally sold for more money than I ever thought I'd be involved with.

Design ME at JR Auto

Jatinderpal

Major: Mechanical Engineering

During my time at JR I designed stations for assembly lines, modified existing assemblies, and detailed and checked design prints.

Engineering Internship at Rose Medical

Bridget

Major: Mechanical Engineering

At Rose Medical I worked on a lot of documentation, fixture calibrations, prototype testing, and actually manufacturing products.

MFP Automation Engineering Co-Op Semester

Brianna

Major: Mechanical Engineering

I spent time in our production shop learning basic shop practices including milling, welding, making hoses for power units, testing the units, as well as prepping for paint. During my time in engineering, I gained more experience with AutoCAD for our 2D drawings of power units. With more part familiarization, I was able to begin quoting my own projects.

Cascade Engineering Co-op

Sara

Major: Mechanical Engineering

I worked in the CFI (center for innovation) department where most of the engineers are located. However, much of the work for my projects required me to go to other plants on the campus to view either parts or the work cells for different machine presses.

I worked mainly on two projects, however I did help with some other testing studies as well. One of my main projects was designing and building an inspection table for one of the machines. The boxes of parts would sit on the table to make it easier for the supervisor of the press to inspect the parts. This project helped me gain a lot of problem solving skills as the project was almost entirely self led.

The other main project I worked on was helping create a tool for some of our customers. Our trash containers get shipped out in stacks of 10 and often are hard to pry apart. There was already a tool in place that helped de-stack these containers, however, it was not very user friendly. Along with another engineer, I helped create a new tool that is much more user friendly to de-stack the containers.

Co-op

David

Major: Mechanical Engineering

I have spent a majority of my time working on the architectural mechanical systems in universities throughout west Michigan including GVSU. I have designed, commissioned. and coordinated the mechanical systems that help buildings operate efficiently and conserve energy.

Mechanical Engineering Co-op

Jordyn

Major: Mechanical Engineering

Throughout the summer I was able to work with several departments in order to complete order entry tasks, cost analysis drawings using AutoCAD, order-completion drawings, and drawing modifications. I also had the opportunity to travel to Mexico for two weeks to aid in part identification. All of these tasks helped further my knowledge of products within the company as well as how to use different programs in order to properly complete my job.

GMCH Co-op 2

Alex

Major: Mechanical Engineering

I worked on completing testing that was requested by the other engineers. Some specific tests were system response and component response of a new valve train system; component durability and robustness benchmarking of alternative materials on cam phasing components, and some EOT component measurements for the diesel engine programs.

Engineering Co-op Intern

Kevin

Major: Mechanical Engineering

This semester, I designed fixtures that are being used to create one of the monitor mounting systems that we sell. These fixtures allow the systems to be built in a faster and safer manner than was previously used.

I also worked on designs for a cart that has a magnet in it so that hospitals can use tablets on the cart, move the carts around and not have the tablets fall off.

JR Automation Quoting Co-op

Joe

Major: Mechanical Engineering

My tasks included everything from customer facility visits, concept development, and cost development, to presenting these ideas and costing to lead managers and then to engineers from the companies I would be submitting these quotes to. I was also able to work with our research and development team to develop and present innovative solutions to customers requesting technology that hadn't been previously tested.

Koops Mechanical Engineering Co-op

Adam

Major: Mechanical Engineering

As a mechanical engineering co-op I was placed as the lead mechanical engineering on projects, assigned to work on engineering changes for machines that have been shipped to the production plant, traveled to several productions plants, worked one-on-one with several customers, participated in and lead design reviews, and worked on designs with other mechanical engineers. Koops ensures that their co-ops are treated as mechanical engineers as soon as they enter the workplace. I would say that my experience was nothing short of having a full-time engineering position at Koops.

Co-op #2

Luke

Major: Mechanical Engineering

This Past Semester I completed the tooling of a screw machine for a new job launch, I executed several design projects (tool holders, wash fixtures, and custom automation components), and improved an automated sorting system which I designed and implemented during my first co-op experience. I was also given the opportunity to represent the company during a customer visit and an out of state supplier visit.

Learning to Design Machines

Andrew

Major: Mechanical Engineering

I was responsible for designing portions of machines, detailing prints for parts that were to be made, completing design checks for other engineers, supporting builders, and completing redlines for completed jobs.

Winter Semester Co-Op (Round 2)

Joseph

Major: Mechanical Engineering

3D printing is a daily task that I've been assigned to. Running the 3D printer is a big responsibility, because without it, the prototypes being built in the advance prototype department (my department) would come to a halt. I've also done a lot of benchmarking, where I take data and tear down new production mirrors. It's a nice task that really lets me appreciate the engineering put into outside mirrors that a regular person couldn't see. It also helps me learn more about Magna Mirrors and what we specialize in and try to improve. I have mostly been working on projects where lighting is the main objective. These projects are really fun because of the challenge it gives me. Lighting is a really complex concept that I have little understanding of, but working with an engineer over the past couple months in my department has allowed me to learn much more.

EGR Co-op 2

Christian

Major: Mechanical Engineering

Manufacturing process improvement

Rotary Engine Experience

Mitchell

Major: Mechanical Engineering

I worked on tasks related to the rotary engine program including tasks such as testing parts to determine cause of failure, working with the build log and disposition of parts, doing tolerance stackups to determine if a non-conforming part could be used as is, and working with a balancer to balance parts for the engine.

Co-Op Experience at Rose Medical; Winter, 2016

Travis

Major: Mechanical Engineering

As a project engineering intern, I primarily supported the engineering team. This entailed manufacturing prototype parts, improving process efficiency, manufacturing of various fixtures, and general support of the company as a whole.

Read More About Co-Op Experience at Rose Medical; Winter, 2016

JR Automation Technologies Co-op II

Jon

Major: Mechanical Engineering

I have worked for JR for two semesters and throughout that time have spent a vast majority of time quoting material handling cells, assembly cells, both fully auto, partially auto, and manually operated machines. This past rotation I worked in design and help detail two large press for pressing some components together. I dipped a bit in quoting to help knock out a few of the RFQ's that we were going to be late, but everything worked out. As far as the design aspect goes, datum features are my new best friend. This is because of the large amount of detailing that I completed,which really help me to think about how a machinist would actually go about making the specific part.

Tool Design

Andrew

Major: Mechanical Engineering

I solved multiple production issues using Pam-Stamp metal forming simulation software to identify key issues and suggesting solutions. I have designed production tooling and fingers to produce new parts. I have done miscellaneous design work for our presses as well. I have also done some gage design for our quality processes.

On the job with viastore

Ethan

Major: Mechanical Engineering

This rotation I spent most of my time in the field. I oversaw installations as well as engineering solutions to problems as they arose. I was given responsibilities throughout my time that were key to the completion of the projects.

Winter 2016 Mechanical Engineering Co-op

Parker

Major: Mechanical Engineering

On a weekly basis, I performed a variety of tests on products ranging from those sold at local big box department stores to products newly developed from Attwood's engineering department. I also worked with my fellow engineering co-op students to develop a new product for the company, as well as on an individual project for the lab.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.